Case Study

UK's largest

clinker store designed using LUSAS

- Evaluation of pre-stress load

transfer

- Prediction of induced

loadings and displacements

- Static, soil-structure and nonlinear

analysis

LUSAS Civil & Structural analysis software

has

been used by consulting engineers Oscar Faber to predict induced loadings and subsequent

deflections on the wall and foundations of a 120000 tonne capacity post tensioned clinker

store for Rugby Cement. The store is part of a design and construct contract let to Bierrum and Partners Limited by AMEC Construction

Limited and with an internal diameter of 55 metres, a wall height of 35 metres and a roof

height of 54 metres, the store is the one of the largest in the world.

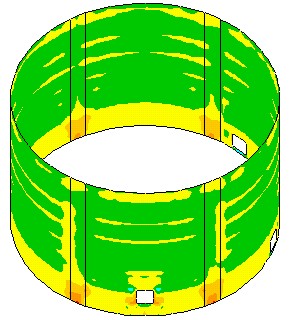

With a wall thickness of 500mm, the store is relatively

thin walled and being post tensioned required a full 3D geometric nonlinear analysis using

LUSAS to prove the design. Thick shell elements of various thicknesses modelled the store

wall, upper ring beam, tendon anchorage pillasters and foundation. Beam elements modelled

steel stiffening frames around conveyor openings. 2D plane strain and axisymmetric

analyses of the soil / structure interaction were done initially to assess the effect of

the weight of stored material on foundation rotation. The results obtained were then used

to specify spring support conditions to the base of the wall in the 3D analysis.

|

|

|

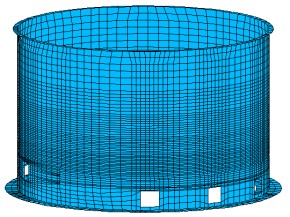

| Finite

element model |

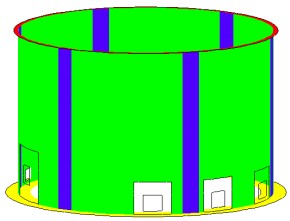

Geometric

assignments |

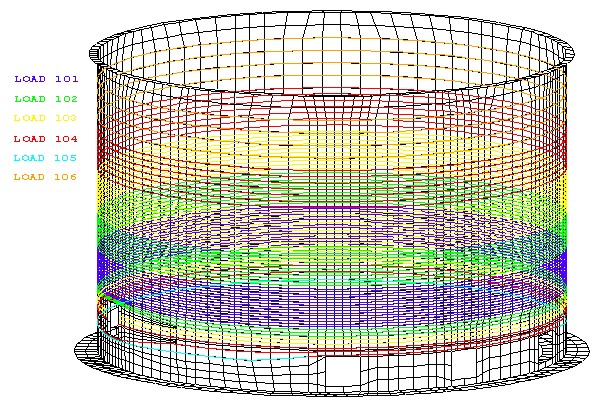

Eccentric

discharging of clinker using underground conveyors causes uneven pressure loads against

the wall of the store. Assessment of this non-uniform partially-full situation together

with other load cases such as loads at pre stress transfer, wind loading on the empty

store before and after post tensioning, and a full store with long term tendon loads were

the key to obtaining a full understanding of the response of the structure.

LUSAS Civil

& Structural provides comprehensive results processing facilities. The use of a

variety of contouring features clearly illustrated the effects of the different loading

considered. Contour plots showing forces, bending moments and out of plane shears in the

wall and foundation were produced. Deflection plots showed model deformation under each of

the applied loads. For each load case horizontal and vertical

Clark-Nielsen forces were

plotted for both faces to aid reinforcement detailing. By using the

Clark-Nielsen facility

in LUSAS, in plane forces, bending and torsional bending moments are combined into a set

of orthogonal forces - ideal for reinforcement design.

|

|

|

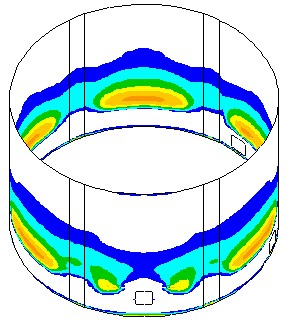

| Horizontal

Clark-Nielsen forces |

Vertical

out-of-plane shear forces |

By making use of LUSAS Civil & Structural analysis Oscar

Faber obtained a comprehensive set of results that showed the behaviour of the store under

all loading conditions. "LUSAS modelled the stress stiffening effects on the store

very well", said Phil Benson of Oscar Faber. "The details given on foundation

movement and stresses at tendon jacking points were of particular use to us in proving the

design. LUSAS helped us to save design time and allowed us to produce a more efficient

reinforcement arrangement due to the Clark-Nielsen contour plots produced for each

loadcase."

"The details given on foundation

movement and stresses at tendon jacking points were of particular use to us in proving the

design. LUSAS helped us to save design time and allowed us to produce a more efficient

reinforcement arrangement due to the Clark-Nielsen contour plots produced for each

loadcase."

Phil Benson, Oscar

Faber

Find out more

Other LUSAS Civil &

Structural case studies:

|