User Area > Advice

Element quality

It is essential that a

finite element solution should converge to the “exact” solution as the number of

elements is increased (where “exact” is measured according to assumptions made

in the model). Moreover, the convergence should also be monotonic, that is converging from

one direction only - not oscillating in some manner about the exact solution. The

following diagram shows both monotonic and non-monotonic convergence.

The basic requirements

for guaranteed monotonic convergence are

-

The displacement function should

be such that it does not permit straining of an element to occur when the nodal

displacements are caused by rigid body displacement. This is self evident, since an

unsupported structure in space will be subject to no restraining forces

-

The displacement function should

be of such a form that if nodal displacements produce constant strain conditions such

constant strain will be obtained. This is essential since significant mesh refinement will

cause near-constant strain conditions to occur in elements and they must be able to handle

this condition correctly

-

The displacement function should

ensure that the strains at the interface between elements are finite (even though

indeterminate). By this, the element boundaries will have no “gaps” appear

between them and, hence, will show a continuous mesh.

These are satisfied

by all elements in LUSAS when they are of a general (but admissible) geometric shape. The

recommended mesh sensitivity tests to ensure that the analysis results are not affected by

mesh coarseness rely on this being true.

The slope of the convergence curves in the previous diagram measure the

rate at which mesh refinement attains the exact solution. The magnitude of the slope is

determined by the order of the elements used in the mesh – higher order elements

providing faster convergence than low order.

It has been found,

however, that the rate of convergence for a given element (low or high order) and for any

size (large or small) is significantly dependent on the degree of geometric distortion

present in both its undeformed and deformed states. This effect is due to the elements no

longer being able to represent the same order of displacement polynomial after the

geometric distortion as they did without the distortion.

The following table

summarises the effects of various element distortions on the 8-noded plane continuum

element, a similar effect is seen on most other elements.

Undistorted, aspect or parallelogram distortion (if

unrotated) |

Undistorted, aspect or parallelogram distortion (if rotated) |

Angular distortion |

Excessive midside node distortion |

1, x, y, x2,

xy, y2, x2y, y2x |

1, x, y, x2,

xy, y2 |

1, x, y |

1, x, y |

The first column in the table gives the displacement field that

can be exactly modelled by the element when the element is undistorted and unrotated or is

subjected to an aspect ratio or parallelogram distortion only. The second column is

similar but includes the effect of general element rotation.

What is most

noticeable is that an angular or midside node distortion significantly reduces the

predictive capability of these elements. With such distortions the elements can represent

only linear displacement variations in x and y exactly compared to the original quadratic

capability.

The definitions of

these element distortions are presented in the following diagrams:

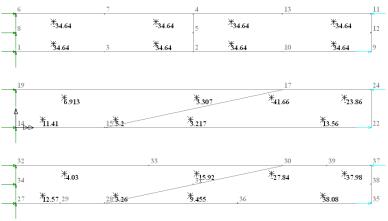

An example of the

effect of angular distortion is seen when considering a simple cantilever beam modelled

with plane elements and loaded with a moment on the free end. The top picture represents

the correct results obtained at Gauss points when using an undistorted mesh of 8-noded

elements and integrated with a 2x2 rule. The middle picture shows the results

obtained with distorted 4-noded elements and the bottom picture, the results from the

distorted 8-noded mesh.

For

this reason LUSAS writes WARNING messages to the output file

when (a) midside nodes are not centred

sufficiently, (b) excessive midside node distortion is present

and (c) element aspect ratios

exceed a default limit.

It

is also essential to view unsmoothed

contours to detect significant discontinuities at element boundaries

(since it is difficult to construct a robust test for angular

distortion and rotated configurations).

Additionally, the

convergence rate of elements is reduced in the presence of localised singularities as a

result of, for example, the presence of single point loads or point reactions. In such

cases, errors in both the displacement and stress will be locally infinite, although the

overall solution may well be acceptable. Similar localised behaviour will exist near

re-entrant corners where stress singularities exist in elastic analysis. Such

localisations are significantly ameliorated by modelling sharp corners with a smooth

radius or by applying loading and supports over an area.

Finite

Element Theory Contents

Aspect

Ratio Warnings

The

Jacobian Matrix

Finite

Element Equilibrium

Numerical

Integration

|