LUSAS New Release and Software Feature Videos

Watch a short video to find out about

new software releases and see

specific features of LUSAS in action.

See also:

LUSAS

conference papers and presentations LUSAS

conference papers and presentations

LUSAS

webinar recordings LUSAS

webinar recordings

LUSAS Version 23.0

LUSAS Version 22.0

LUSAS Version 21.1 and 21.0

|

|

|

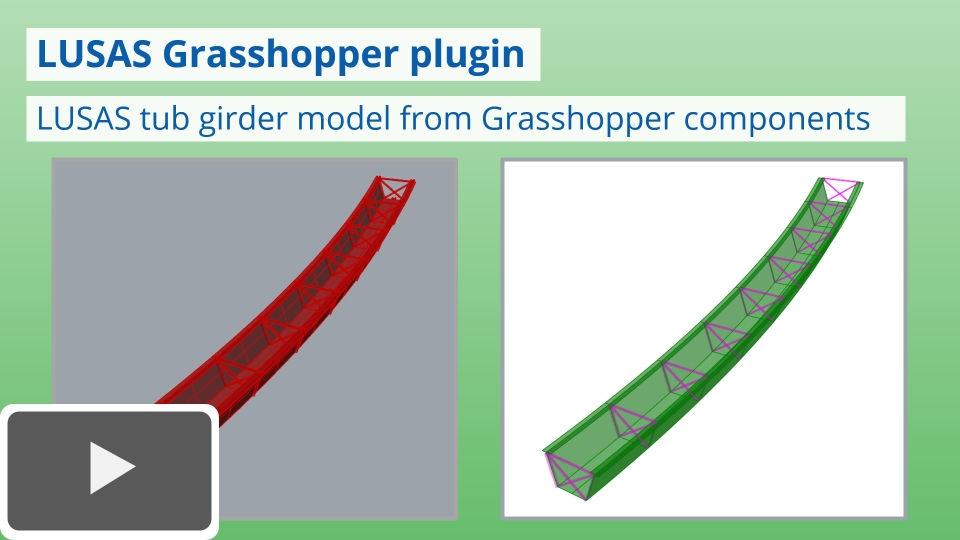

LUSAS

tub girder model created from the LUSAS Grasshopper plugin

(2:39)

LUSAS

tub girder model created from the LUSAS Grasshopper plugin

(2:39)

|

|

|

|

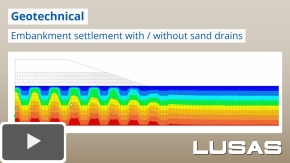

Embankment

settlement with / without the use of sand drains (4:11)

Embankment

settlement with / without the use of sand drains (4:11)

|

|

|

|

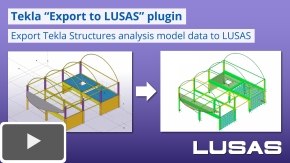

Tekla

"Export to LUSAS" plugin (2:33)

Tekla

"Export to LUSAS" plugin (2:33)

-

Export Tekla

Structures analytical model data

for use with LUSAS in order to solve a linear static

analysis and optionally extend the model to carry out

design checks or to include loading, dynamics, nonlinear

or other advanced options. (Version 21)

|

|

|

|

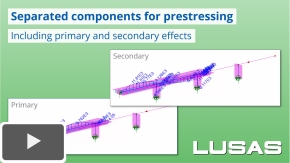

Separated

components for prestressing (3:44)

Separated

components for prestressing (3:44)

-

Watch

how, for beam models, it is

now possible to calculate and view, for each stage of

construction, primary and secondary load effects arising

from prestressing, and primary effects from each tendon

loss type (friction, anchorage, elastic shortening,

creep, shrinkage and relaxation).

(Version 21.1)

|

|

|

|

Enhanced

traffic loading and bridge assessment (1:37)

Enhanced

traffic loading and bridge assessment (1:37)

|

|

|

|

Updated

Masonry Bridge Wizard (5:19)

Updated

Masonry Bridge Wizard (5:19)

|

|

|

|

LUSAS

Version 21 Overview Presentation (7:57)

LUSAS

Version 21 Overview Presentation (7:57)

|

|

|

|

Post-tensioned Bridge

Wizard (10:00)

Post-tensioned Bridge

Wizard (10:00)

|

|

|

|

Revit

"Export to LUSAS" plugin (2:08)

Revit

"Export to LUSAS" plugin (2:08)

|

|

|

|

Vehicle load

optimisation using Envelope Runs (4:33)

Vehicle load

optimisation using Envelope Runs (4:33)

|

|

|

|

Non-reflecting

boundaries (3:22)

Non-reflecting

boundaries (3:22)

|

|

|

|

Embedded rebar in

continuum models (3:56)

Embedded rebar in

continuum models (3:56)

-

Model reinforcement bar

arrangements in 2D and 3D continuum models or import

from Revit or other CAD software. (Version 21)

|

|

|

|

Improved

visualisation tools (1:09)

Improved

visualisation tools (1:09)

|

|

|

|

Pedestrian dynamics

(8:41)

Pedestrian dynamics

(8:41)

-

Easily

define excitations for a single pedestrian, groups of

walkers or joggers, to suit international codes of

practice and generate a transient analysis with the

appropriate moving and varying loads. (Version 21).

|

|

|

|

Seepage modelling

using phreatic surfaces (1:35)

Seepage modelling

using phreatic surfaces (1:35)

|

LUSAS Version 20

LUSAS Version 19 and 19.1

|

|

|

LUSAS

Version 19 (1:00)

LUSAS

Version 19 (1:00)

|

|

|

|

LUSAS

Version 19 Overview Presentation - More Productivity

(10:02)

LUSAS

Version 19 Overview Presentation - More Productivity

(10:02)

|

|

|

|

LUSAS

Version 19 Overview Presentation - More Design

(7:57)

LUSAS

Version 19 Overview Presentation - More Design

(7:57)

|

|

|

|

LUSAS

Version 19 Overview Presentation - More Applications

(6:10)

LUSAS

Version 19 Overview Presentation - More Applications

(6:10)

|

|

|

|

Steel Composite

Bridge Wizard (10:23)

Steel Composite

Bridge Wizard (10:23)

-

Watch

how to create a beam and shell model of a 3-span curved

steel composite bridge using the Steel Composite Bridge

Wizard. Composite sections, girders, spans,

supports are defined prior to generating an initial

bridge model from the input data. Stiffeners and

cross-bracing details are added also using the wizard

and the bridge is re-generated to show their inclusion

in the model. After solving the model, bending moment

results are displayed for a selected girder by using the

slice resultants facility. (Version 19.0)

|

|

|

|

Composite Bridge Deck

Design (6:54)

Composite Bridge Deck

Design (6:54)

|

|

|

|

Branched

analysis for staged construction checks (5:07)

Branched

analysis for staged construction checks (5:07)

-

Watch how to

use the branched analysis facility to set-up and carry

out buckling, stability and other what-if checks for chosen

construction stages, or to consider an alternative

construction sequence. (Version 19.0)

|

|

|

|

Phi-C reduction soil

stability checks (1:44)

Phi-C reduction soil

stability checks (1:44)

|

|

|

|

Temperature

profile loading (1:25)

Temperature

profile loading (1:25)

-

Watch how to

model temperature profile loading of a concrete deck

with a slab and surfacing to Eurocodes. From defined

values the temperature loading is visualised over the

height of the deck and assigned to the model.

Temperature profile loading to other codes is also

available, as is manual definition of profiles.(Version

19.0)

|

|

|

|

Influence

analysis and enhanced

vehicle load optimisation (7:09)

Influence

analysis and enhanced

vehicle load optimisation (7:09)

-

Explains key

aspects of influence analysis and shows how influence

analysis can now also be carried at beam/shell slice resultant

locations. Influence results for selected locations on

the structure are viewed using contour plots, and then

used in a vehicle load optimisation analysis to derive

corresponding traffic loading positions on the bridge

deck. (Version 19.0)

|

|

|

|

CS

458 and AASHTO MBE loading (5:44)

CS

458 and AASHTO MBE loading (5:44)

|

|

|

|

Grillage modelling

(5:44)

Grillage modelling

(5:44)

|

|

|

|

Defining

member reinforcement and RC design checks to AS 5100

(7:06)

Defining

member reinforcement and RC design checks to AS 5100

(7:06)

-

Shows how to

define reinforcement bar arrangements for member sections in a bridge model. RC design

attributes are specified and design checks carried out

on the bridge model showing the range of concrete design

checks and summary, detailed and interaction diagram

results that can be obtained.(Version 19.0)

|

|

|

|

Cut

and cover tunnel modelling (8:58)

Cut

and cover tunnel modelling (8:58)

-

Shows how activation

and deactivation of elements is used to model the

staged construction process of excavating the soil,

installing ground anchors and constructing the tunnel

structure. A linear and a nonlinear analysis is

performed to evaluate using different soil properties,

and a soil stability check is carried out using the

Phi-c reduction method. Live loading to simulate

vehicles passing over the ground above the tunnel is

applied prior to looking at bending moments in the

structural elements. (Version 19.0)

|

|

|

|

Simple

post-tensioned bridge - Part 1 (deck modelling) (8:32)

Simple

post-tensioned bridge - Part 1 (deck modelling) (8:32)

-

Shows the

import and building of a model of a 3-span slab bridge

with twin deep ribs, using beam and shell elements.

Constraint equations are used to tie the surfaces and

beams together to ensure composite action. Concrete

material, supports and gravity are assigned prior to

solving the model. The beam/shell slice resultants

facility is then used to view composite bending moments

along the deck. (Version 19.0)

|

|

|

|

Simple

post-tensioned bridge - Part 2 (prestress loading)

(8:26)

Simple

post-tensioned bridge - Part 2 (prestress loading)

(8:26)

-

Shows the

addition of prestress loading to the bridge deck

modelled in Part 1. Tendon profiles are defined and

assigned to the model, requiring specification of tendon

properties, prestress force and jacking details, and

selection of the lines of the model to which they apply.

Concrete with creep properties and age assignments are

made prior to solving. The deformed shape from

self-weight and prestress loading is viewed for each in

isolation, prior to looking at the effects of both for a

long term loadcase. (Version 19.0)

|

|

LUSAS Version 18

|

|

|

LUSAS

Version 18 Update Presentation (10:43)

LUSAS

Version 18 Update Presentation (10:43)

|

|

|

|

CAD import

and solid modelling of a cable connector (4:58)

CAD import

and solid modelling of a cable connector (4:58)

-

Shows

third-party file types supported, then imports an IGES

file to create the basic geometry of a cable connector.

A solid model is defined and meshed showing the difference in

using linear and quadratic elements. Supports and

loading are added to represent in-service use, and once

solved, Von-Mises stresses are obtained

and additionally plotted on slice sections taken through

the connector. (Version 18.1)

|

|

|

|

Hygro-thermal

modelling of a concrete dam (10:50)

Hygro-thermal

modelling of a concrete dam (10:50)

|

|

|

|

Vehicle

load optimisation to UK bridge assessment code CS 454 (4:10)

Vehicle

load optimisation to UK bridge assessment code CS 454 (4:10)

-

Shows how to

carry out a vehicle load optimisation analysis on a

three-span flat slab bridge modelled using shell

elements. Locations of interest are identified, and an

influence analysis run to calculate vehicle loading

patterns for maximum and minimum effects at the chosen locations. (Version 18.1)

For more

information see Vehicle

Load Optimisation

|

|

|

|

Train/rail

load optimisation (8:23)

Train/rail

load optimisation (8:23)

-

Shows how to

carry out train/rail load optimisation analysis on a

two-span box beam bridge modelled using shell

elements. Tracks, including a crossover and a signal

stop location, are defined and visualised, and after

running an influence analysis, critical rail loading

patterns for a chosen design code are obtained for

selected track arrangements. (Version 18.0)

For more

information see Vehicle

Load Optimisation

|

|

|

|

Defining

member reinforcement and carrying out RC design checks

(14:03)

Defining

member reinforcement and carrying out RC design checks

(14:03)

-

Shows how to

define reinforcement bar arrangements for beam and

column members in a simple building frame model, and

then how more complex section

reinforcement details are defined for arbitrary and

tapering sections in a bridge model. RC design

attributes are specified and design checks carried out

on the bridge model showing the range of concrete design

checks and summary, detailed and interaction diagram

results that can be obtained.(Version 18.0)

For more

information see RC

Frame Design.

|

|

|

|

RC

design checking of a circular tank wall (9:36)

RC

design checking of a circular tank wall (9:36)

|

|

LUSAS Version 17

|

|

|

|

LUSAS

Version 17 Update Presentation (7:32)

LUSAS

Version 17 Update Presentation (7:32)

-

Version 17.0

sees steel frame design checking and vehicle load

optimisation capabilities extended to include EN1993-2: 2006 Eurocode

3, prestress

enhancements, additional creep and shrinkage models, and

new facilities for soil-structure interaction modelling.

New viewing and editing features simplify the management

and changing of attribute assignments, improving general

ease-of-use. Watch this short overview presentation to

find out more. (Version 17.0)

|

|

|

|

Steel

bridge design

to EN1993-2 Eurocode 3 (6:05)

Steel

bridge design

to EN1993-2 Eurocode 3 (6:05)

-

Design checks for a steel railway bridge are carried out to EN1993-2: 2006 Eurocode 3: Design of steel structures - Part 2: Steel Bridges. Shows viewing of utilisation factors, and creation of a member report for a selected member to demonstrate the transparent nature of the LUSAS steel design checking facility, that shows the calculations made, revealing every step, every clause reference, and every

formula. (Version 17.0)

For more

information see Steel

Frame Design.

|

|

|

|

Post-tensioning in shell models (5:10)

Post-tensioning in shell models (5:10)

|

|

|

|

Easier

viewing and editing of

attribute assignments (4:18)

Easier

viewing and editing of

attribute assignments (4:18)

-

Shows how to use the new loading attributes editor and the new attributes assignment dialog to make individual changes for multiple

selections. An incorrectly entered tendon force for a post-tensioned model is shown to be easily spotted and corrected. Then, by copying and pasting dynamic load factors from a spreadsheet to replace constant values used by a moving load, it is shown that the dynamic effect of a tank crossing a structure can be modelled. (Version 17.0)

|

|

LUSAS Version 16

|

|

|

LUSAS

Version 16 Update Presentation (13:48)

LUSAS

Version 16 Update Presentation (13:48)

-

Version 16

marks a new era for LUSAS with the addition of comprehensive design checking tools for steelwork, and a host of other new features and enhancements that improve general usability and make collaboration between design teams easier.

Watch this short

introductory presentation video to find out more. (Version

16.0)

|

|

|

Steel

bridge design to AASHTO LRFD 7th Edition (7:29)

Steel

bridge design to AASHTO LRFD 7th Edition (7:29)

-

Design code-based combinations are created followed by steel frame design attributes that specify member design values, members lengths and end conditions used in the determination of buckling capacities. Design checks are carried out to AASHTO LRFD 7th edition showing utilisation factors, and a member report is created for a selected member to demonstrate the transparent nature of the LUSAS steel design checking facility that shows the calculations made, revealing every step, every clause reference, and every formula. (Version 16.0)

For more

information see Steel

Frame Design.

|

|

|

|

Beam

and shell slicing of results for a composite bridge deck (5:14)

Beam

and shell slicing of results for a composite bridge deck (5:14)

|

|

|

|

LUSAS eigenvalue frequency analysis using the loading to mass facility (2:19)

LUSAS eigenvalue frequency analysis using the loading to mass facility (2:19)

-

Following an initial linear analysis, eigenvalue controls are specified in separate analyses, firstly without using the loading to

mass option, and then using the loading to mass

option for comparison purposes. (Version 16.0)

|

|

|

|

Steel

frame modelling (10:37)

Steel

frame modelling (10:37)

-

Modelling of

a multi-storey steel framed building showing use of

layout grids and generation of columns, bracing and

floor slab geometry. The use of rigid zones to

accurately model steel members is explained together

with the use of floor loading that distributes

floor sub-beam and imposed loads automatically to

supporting perimeter beams. Merging-in of a model of the upper tower is performed to show one of the new

collaboration features. (Version

16.0)

For more

information see Steel

Frame Design.

|

|

|

|

Steel

frame design to EN1993-1-1 Eurocode 3 (6:28)

Steel

frame design to EN1993-1-1 Eurocode 3 (6:28)

-

Design code-based combinations

are created followed by

steel frame design attributes that specify member design

values, members lengths and end conditions used in the

determination of buckling capacities. Design checks are

carried out to EN1993-1-1 Eurocode 3 showing utilisation factors and a member

report is created for a selected column to demonstrate the

transparent nature of the LUSAS steel design checking facility

that shows the calculations made, revealing every step,

every clause reference, and every formula. (Version

16.0)

For more

information see Steel

Frame Design.

|

|

|

|

Design of skewed

3-span reinforced concrete bridge deck to Eurocode (13:11)

Design of skewed

3-span reinforced concrete bridge deck to Eurocode (13:11)

|

|

LUSAS Version 15

|

|

|

Building a

footbridge model for

linear analysis (9:08)

Building a

footbridge model for

linear analysis (9:08)

-

Model

building of a footbridge using point and line features, creation and

assignment of geometric and material properties,

meshing, gravity loading and supports. (Version 15.2)

|

|

|

|

Progressing the

footbridge model

for linear dynamics (6:23)

Progressing the

footbridge model

for linear dynamics (6:23)

|

|

|

|

Pedestrian

footbridge

loading assessment to

Eurocode using UK National Annex (13:35)

Pedestrian

footbridge

loading assessment to

Eurocode using UK National Annex (13:35)

|

|

|

Seepage

through an earth dam (14:28)

Seepage

through an earth dam (14:28)

|

|

|

Beam

and shell modelling of a post-tensioned bridge (12:55)

Beam

and shell modelling of a post-tensioned bridge (12:55)

-

Covers the

building of a simple model of a 3-span slab bridge

with twin deep ribs, using shell and beam elements and

constraint equations to tie the surfaces and beams

together to ensure composite action. Tendon profiles

are defined and assigned to the model, requiring

specification of tendon properties, prestress force

and jacking details, and selection of the lines of the

model to which they apply. The deformed shape from

self-weight and prestress loading is viewed for each

in isolation, prior to looking at the effects of both

in a load combination. (Version 15.1)

|

|

|

Staged

construction modelling of a dam (20:08)

Staged

construction modelling of a dam (20:08)

-

Illustrates

the procedures involved in preparing a dam model (that

has been imported from an IGES file) for an initial

linear static structural analysis - as required prior to

developing the model further. The assignment of a

volume mesh to the model, and the applying of

structural material, supports, and gravity loading

only is covered. Activation and deactivation of

elements is used to represent the staged construction

process of pouring individual lifts of concrete. After being solved the stresses in each lift

are investigated. A time-history response graph for a

selected location is produced to show stress changing

with each loadcase. An animation of the construction

stages is produced. A separate model is used to show

heat of hydration modelling involving the use of

thermal material properties with corresponding thermal

temperatures and stresses arising from the analysis

being visualised. (Version 15.1)

|

|

|

Modelling

and results / reporting overview for a 3-span box

structure (18:15)

Modelling

and results / reporting overview for a 3-span box

structure (18:15)

-

An initial

import of a DXF and an IGES file showing automatic

meshing and rendering facilities is followed by line

beam modelling of a 3-span box beam structure. The

assignment of user-defined section properties is shown

for standard, linear and tapered box sections, and a

method for finding model geometry without material

assigned is highlighted. Results are viewed for

bending moments and stresses both on the fleshed model

and in a tabular results format. A report is created

showing user-defined outputs and how saved views of

the model and results are automatically updated each

time a report is created. (Version 15.1)

|

|

|

Interactive

modal dynamics and rail track-structure interaction

analysis (14:04)

Interactive

modal dynamics and rail track-structure interaction

analysis (14:04)

-

Overview

of the features and capabilities of the LUSAS

Interactive Modal Dynamics software option (IMDPlus)

with specific reference to rail use, and of the LUSAS

Rail Track Analysis software option, which permits

track/structure interaction analysis to the

International Union of Railways Code UIC 774-3 and to

the relevant sections in Eurocode 1. (Version

15.1)

|

|

|

Saved

views, results

extraction and report generation (8:50)

Saved

views, results

extraction and report generation (8:50)

-

A simple

integral bridge model is used to show the creation and

use of Saved Views, graphing of results data, the

setting of threshold values for results listings,

one-click member reporting, and auto-updating of the

saved views and one-click member reports for a revised

model. (Version 15.1)

|

|

|

Construction

table reporting (5:31)

Construction

table reporting (5:31)

-

Use of the

LUSAS construction table facility on a box cantilever

model to report tables of displacement data for a

staged construction analysis. Tables shown include a camber table

- as used to set-out a structure towards a target (as-built) profile;

a displacement history table, which reports the absolute displacement of a series of key-points at each stage with reference to an undeformed geometry

'datum'; and an incremental displacement table, which reports the stage-by-stage deformation of a

structure and tabulates the relative displacements between each

stage. (Version

15.1)

|

|

|

Defining

rigid zones (9:32)

Defining

rigid zones (9:32)

|

|

|

Easy-to-use

lift-off supports and RC slab design to AASHTO (7:36)

Easy-to-use

lift-off supports and RC slab design to AASHTO (7:36)

|

|

|

Direct

method influence analysis and Traffic Load Optimisation for

beams to AASHTO (5:51)

Direct

method influence analysis and Traffic Load Optimisation for

beams to AASHTO (5:51)

|

|

|

Easy-to-use

lift-off supports and RC slab design to Eurocode (9:32)

Easy-to-use

lift-off supports and RC slab design to Eurocode (9:32)

-

A simple

bridge model is used to show the use of the multiple

analysis facility, the use of lift-off supports, and

slab design showing bar reinforcement details and

crack checking based on EuroCode 1991-2. (Version

15.0)

|

|

|

Direct

method influence analysis and Traffic Load Optimisation for

beams to Eurocode (7:37)

Direct

method influence analysis and Traffic Load Optimisation for

beams to Eurocode (7:37)

|

|

|

Cable

tuning analysis for linear structures (8:15)

Cable

tuning analysis for linear structures (8:15)

-

For many

structures it is vital control the deflected shape

during construction or under imposed loading. Here,

the cable tuning analysis facility is used to

calculate cable forces in a cable stayed footbridge

to meet a user-defined pre-cambered profile, as well

as limiting the main tower displacement and bending

moment to acceptable values. (Version 15.0)

|

|

|

Modelling

of active/passive soil behaviour with multi-linear joint

material (5:53)

Modelling

of active/passive soil behaviour with multi-linear joint

material (5:53)

-

Shows a soil-structure

interaction (SSI) problem where structural-element

and ground displacements are dependent upon one

another. An Active / Passive soil joint is set up

for an embedded retaining wall to cater for

lateral pressures increasing with depth, and the

joints are also pre-loaded with an at-rest pressure

at the beginning of the analysis. A parametric

investigation of soil properties and the effects on

bending moments in the wall is also done. (Version

15.0)

|

|

See also:

LUSAS

conference papers and presentations LUSAS

conference papers and presentations

LUSAS

webinar recordings LUSAS

webinar recordings

|