Software Tour

Analysis software for composites engineering

LUSAS

Composite contains a comprehensive range of unrivalled

engineering analysis facilities to cater for all types of composite

design. LUSAS

Composite contains a comprehensive range of unrivalled

engineering analysis facilities to cater for all types of composite

design.

From simple failure prediction using a number of failure

criteria including Tsai-Hill, Hoffman and Tsai-Wu through to

advanced delamination failure modelling, LUSAS Composite will help

shorten your design and checking times giving reliable results every

time.

For structural and

bridge applications, model Fibre Reinforced Polymer (FRP),

laminated glass, reinforced concrete using

the smeared reinforcement technique, and carry-out gradual

through-thickness masonry arch cracking assessments using layered

shell elements.

The intuitive Windows

user interface gives easy access to the full range of powerful

modelling and results processing facilities, together with on-line

help. Regarded as a leader in engineering

analysis, LUSAS Composite is rich in powerful and advanced

features to meet your analysis needs and extend your design

capabilities.

Many real-life

illustrative uses of the software can be seen by visiting our

engineering case studies

page.

Why use LUSAS

Composite?

- Provides cost-effective structural modelling and analysis

of all types of composite component, in one

software package.

- Feature-based

modelling that allows mixing of element types in

the same model.

- Benefit from

advanced nonlinear

geometry, material and contact modelling

- Customise the

softtare using the LUSAS Programmable Interface.

- LUSAS is a

long-established and trusted provider to industry leaders, and

LUSAS Technical Support is stated, by its users, to be simply:

"The best in the business."

Ideal

for all types of composite analysis Ideal

for all types of composite analysis

By using the unrivalled

state-of-the-art element libraries and material models of LUSAS Composite

a host of composite engineering problems can be solved.

- Built-in associativity ensures

that if the model geometry is amended, all assigned loadings,

supports and other attributes are automatically moved to suit.

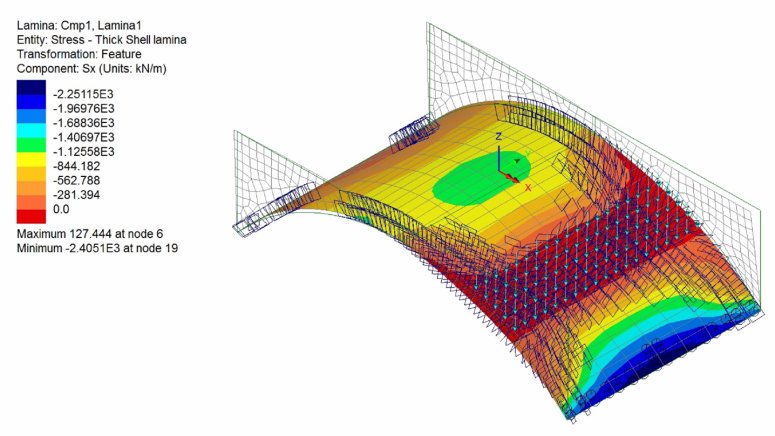

- Extensive GUI results processing

facilities allow extensive contouring, graphing and plotting of

composite specific results.

- By using the advanced scripting

language facilities, user-defined menus and forms can be added

allowing specific repetitive analysis tasks to be performed with

a minimum of user involvement.

- Complete analyses from modelling

to results processing can be automated - and all tailored to

your way of working.

Advanced analysis and

design

Advances in composite technology

require advanced software solutions. LUSAS Composite offers

these solutions now to give you the edge over your competitors.

LUSAS Composite gives you:

- An advanced element set.

- Use of all LUSAS material models.

- Fast Iterative Solver Technology.

- Access to advanced analysis

options.

A software key system means that you

can call us at any time for a key to unlock these powerful options

so that you can tackle new analyses straightaway.

Easy

lay-up definition Easy

lay-up definition

LUSAS Composite offers a

quicker and simpler way than ever before to define composite lay-ups

independent of the component to be analysed. The properties of each

laminate are defined in a table and each layer given a unique name

for use in results processing - extremely useful where ply drop off

occurs. A lay-up icon provides a useful visual check before the

lay-up is automatically assigned to the underlying geometry. These

unique lay-up procedures dramatically reduce the chance of errors.

Advanced analysis

technology

Because composite components have

different failure characteristics to non-composite components and

are often a complex combination of materials, they pose unique

analysis problems. The use of traditional modelling techniques for

composites can be prohibitively expensive due to the large number of

elements required. Whilst some analysis systems allow laminate

properties to be integrated together to form an homogeneous material

matrix, such systems can only predict failure with a linear

analysis. To model failure correctly, and to assess the residual

strength, nonlinear analysis with LUSAS Composite is

necessary in which the individual laminate behaviour is modelled.

Advanced

composite elements Advanced

composite elements

In addition to shell elements, the

LUSAS 3D solid composite element reduces the model size by allowing

a number of laminates to be modelled by a single element. Where

complex 3D components are built from a number of composite blocks

butted together LUSAS Composite can be used to

automatically generate constraint equations to tie dissimilar meshes

together. This powerful facility can also be used to provide rapid

mesh grading of elements in high stress areas giving you faster

solution times. In addition, linear and nonlinear modelling of

adjacent laminates is possible, allowing you to analyse mixed

material lay-ups.

Composite failure

criteria

Composite failure criteria provide a

means of predicting composite failure from the linear stress

distribution. Within LUSAS the commonly used Tsai-Hill, Hoffman,

Tsai-Wu (with Cowin extension), and Hashin (fibre and matrix)

composite failure criteria are available.

Composite matrix

failure modelling

The Hashin composite damage model has

been implemented to model matrix/fibre failure in composite

materials. The model can be used with the LUSAS solid composite

elements. A set of failure criteria have been used to represent

fibre and matrix failure. These failure criteria result in a

degradation of the Young’s modulus, shear modulus and Poisson’s

ratio where the damage has occurred. Unlike the composite failure

criteria, matrix failure modelling can model progressive failure

using a nonlinear analysis.

Composite

delamination Composite

delamination

Both 2D and 3D composite delamination

interface elements are used in LUSAS Composite. These

elements enable composite delaminations to be modelled using an

incremental nonlinear analysis. Interface elements are embedded into

the finite element model and assigned delamination properties using

a nonlinear material model. If the strength exceeds the strength

threshold value in the opening or tearing directions the material

properties of the interface element are reduced linearly as defined

by the material parameters and complete failure is assumed to have

occurred when the fracture energy is exceeded. No initial crack is

inserted so the interface elements can be placed in the model at

potential delamination sites where they will lie dormant until

failure occurs.

Comprehensive

nonlinear analysis Comprehensive

nonlinear analysis

LUSAS Composite has superior

nonlinear problem solving capabilities.

- Powerful facilities for geometric,

material and boundary nonlinearity are available for problems

involving large deformations, plasticity and collapse.

- Fully automatic load

incrementation, automatic recovery from convergence failure and

restart features are all designed to enable newcomers to

nonlinear analysis to quickly become proficient in solving a

wide variety of nonlinear problems.

- Results processing facilities

provide automatic load-displacement graphs and viewing of

yielded material.

Impact and contact

analysis

For low or high speed impact and

contact problems, contacting elements are automatically detected and

specially developed ‘slidelines’ and ‘slidesurfaces’ handle

the interaction that takes place at contacting regions greatly

simplifying your analyses in 2D or 3D.

Dynamic analysis

Forced response, vibration and

transient dynamics problems can be solved quicker with LUSAS Composite

and, if you wish, by calculating the response for selected loadcases

using the Interactive

Modal Dynamics (IMD) results processing facilities. This gives

shorter analysis times and reduced disk usage compared to a full

transient dynamics assessment.

Working with CAD data

Model information can be exchanged

with a wide range of CAD systems using industry standard exchange

formats such as IGES and DXF, as well as directly with specific CAD

systems using proprietary data exchange formats.

Structural

applications

For structural

and bridge applications, modelling of Fibre Reinforced Polymer (FRP),

laminated glass, reinforced concrete using

the smeared reinforcement technique, and gradual

through-thickness masonry arch cracking assessments can be carried out using

the advanced layered shell elements.

Software

products

LUSAS

Composite is

available as only one software product version, Composite Plus. The Windows user

interface provides for easy and rapid model generation, load

application and combining of loadcase results.

Usage

Element

sets

Software

options

The finite

element analysis capabilities of LUSAS Composite can be extended by

purchasing additional software options.

| LUSAS

High Precision Moulding

To accurately

predict the distortion of laminated composite parts during manufacture

and provide reverse engineered surfaces to create "right first

time" tooling LUSAS offers a consultancy service

using its specialist LUSAS High Precision Moulding (HPM) software

product. By using

this service considerable savings can be made in time to market,

manufacturing time and costs are less, assembly stresses are

lowered, and the time-consuming fitting of any shims is

eliminated. |

|

Global

coverage and support

LUSAS software is

marketed and supported globally by LUSAS and also through a network of

distributors and resellers that cover every continent.

Used by thousands of

users, LUSAS is highly regarded in industry, as demonstrated by an impressive list of

clients, which include many of the top international consultancies.

LUSAS software is also used extensively by government agencies, local

authorities and smaller to medium-size consultants, many of whom find

that the advanced analysis facilities not only expand their

capabilities but also give them a competitive edge.

Universities and

research institutions throughout the world use the academic version of

LUSAS, which provides a steady supply of proficient LUSAS users to

support your use of the software in your industry.

Find out more

|