Software Option for LUSAS

Bridge Plus

Rail Track Analysis

Use the LUSAS Rail Track Analysis software

option to carry out track-structure interaction analysis to the

International Union of Railways Code UIC 774-3 and to the relevant

sections in Eurocode 1. Automatically build models from data

defined in Excel spreadsheets and quickly produce results in

spreadsheet or LUSAS results file formats. Because of the nature of

the analysis, the Nonlinear software option must also be accessible.

Modelling to International Union

of Railways Code UIC 774-3

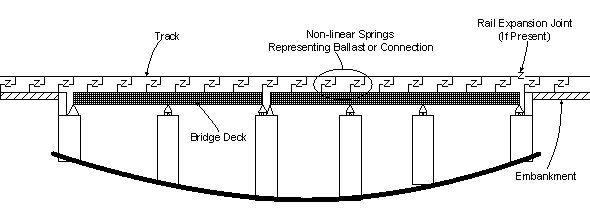

The UIC 773-3

Structural System

UIC 773-3

Track/Deck Modelling

Overview

High Speed and Light Rail projects

require modelling of the interaction of the track with respect to any

supporting bridge structures to ensure that the effects of temperature

and train loading is within specified design limits. To accurately

assess these track-structure interaction effects nonlinear analyses

are required to investigate thermal loading on the bridge deck,

thermal loading on the rail if any rail expansion devices are fitted,

and vertical and longitudinal braking and/or acceleration loads

associated with the trainsets. Ballasted or ballast-free tracks may

need to be considered.

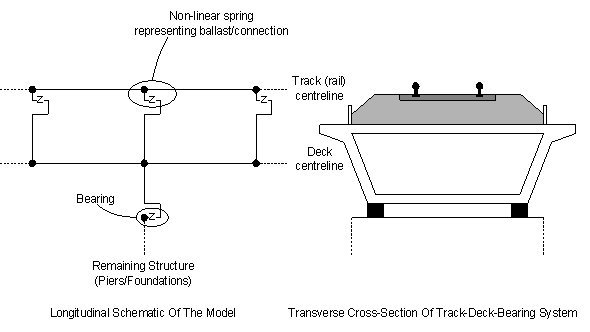

Modelling in LUSAS

Build 3D track and bridge

interaction models automatically from geometric, material property,

and loading data specified within a spreadsheet using conventeint SI

or US uinits. As per UIC774-3, a

user-specified element length is used to define the longitudinal

embankment and bridge features.

-

Define both thermal

loading to the track and train loading due to acceleration and

braking forces.

-

Include rail clips,

ballast movement, bearings and pier stiffnesses in the analysis

model, as required.

-

Consider one train

crossing one or more structures, or multiple

trains crossing the same structure on mixed decks / ballast.

-

Train

loads are permitted outside the extents of the model, allowing

long trains to be passed over structures without having to

have excessively large embankments to model the correct arrival

and departure of the trainset from the structure.

A key feature of the LUSAS Rail Track

Analysis software option is that it automatically updates the material

properties associated with the track/structure interface based upon

the position of the train or trains crossing the bridge.

|

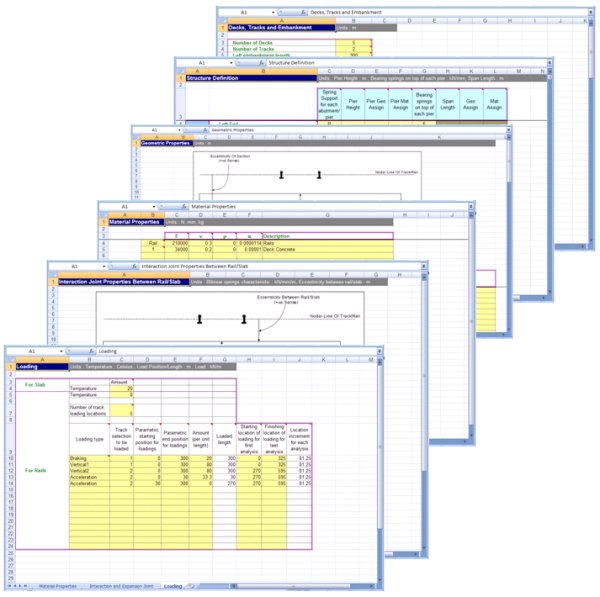

Spreadsheet

input data

Complete

embankment and viaduct model built by LUSAS

|

Enlarged

view of first span |

Exploded

isometric view of part of the model showing embankment

support and the beginning of the first span |

|

Analysis

Consider deck temperature loading in

isolation for subsequent analysis of multiple rail configurations, or

carry out a full analysis considering the combined temperature in the

deck and rail loading. Because the response of the ballast and/or track restraining clips is nonlinear

a nonlinear analysis always needs to be carried out. For

a complete rail track assessment, dynamic effects caused by the

passage of trains that affect the structure itself should also be

considered.

Results available

Produce results automatically in Excel

spreadsheet or standard LUSAS results file format. Envelope results

either inside Excel or by specifying user-defined load combinations

inside LUSAS.

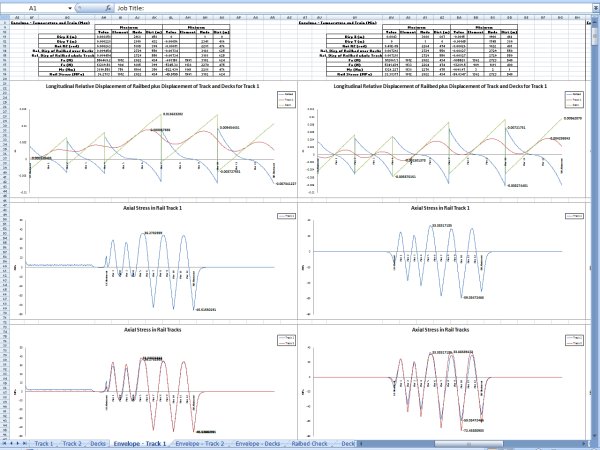

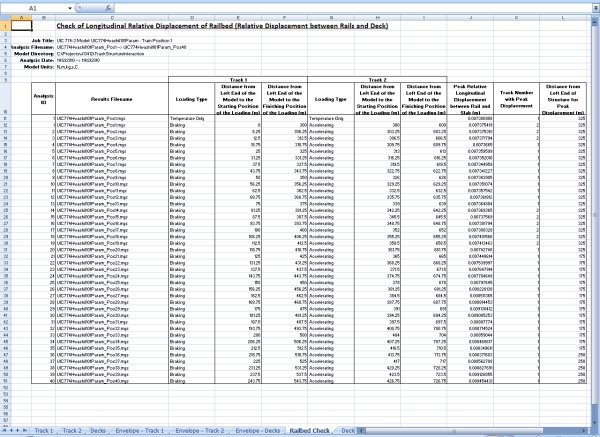

Viewing results in

Excel

Within the Excel results spreadsheet,

separate worksheets contain results for specific areas of interest.

These include:

- Raw results data in summary, graph and tabular form for each track and deck component

- Envelopes of raw track and deck data in summary, graph and tabular form for combinations of temperature and trainset rail loading

- Tables of railbed displacements

- Tables of longitudinal reactions

- Tables of rail stress values.

The three latter tables provide key

results in summary form and allow the quick determination of which

analysis is causing the worst effects for each of the checks that need

to be carried out to the UIC774-3 code. Some example results

worksheets follow.

Envelope of axial

stresses in a rail track

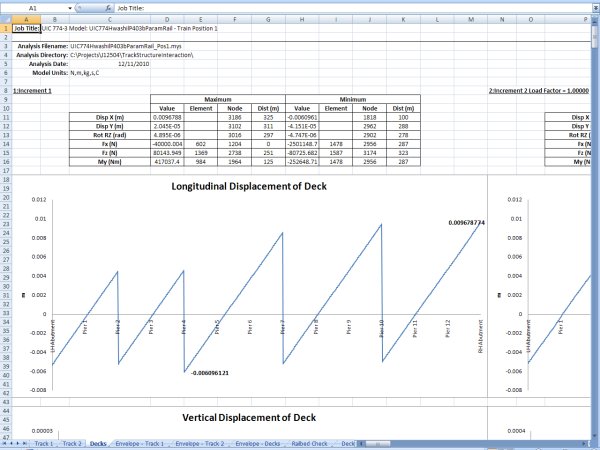

Extract of Deck

worksheet showing longitudinal displacement of deck

Table of relative

displacement of Railbed (relative displacment between rails and

deck)

Viewing

results in LUSAS

Using

LUSAS a variety of similar graphs, tabular listings and results plots

can be obtained to permit checking of most key values against UIC774-3

code, but the creation and viewing of results in the Excel spreadsheet

is superior in that it

provides automatic enveloping, summaries and graphing of the key

results for each loadcase.

Typical axial

force results plot from LUSAS showing force in continually

welded rails from

temperature loading to the deck.

For multi-span and multi-deck structures

such as that shown above the interaction between the embankments / abutments and other decks means that the behaviour can be complex.

As an example, when considering only thermal loading on

a structure having continually welded track it is common to see a

reversal of the axial force / stress in the rails.

Whilst

not apparent from the size of the model shown, the structure illustrated above

is 325m long and consists of two decks, each with two 25m spans followed by three decks, each with three 25m spans. One pier / bearing support for each deck is represented by a restraining spring which takes account of the deflection characteristics of the pier / bearing system in accordance with UIC774-3. All of the remaining piers / bearing supports are roller supports allowing longitudinal movement of the decks. Under the effect of temperature on the structure the axial force / stress in either of the tracks / rails

can be seen to vary. This is primarily due

to the interaction between the movable and fixed structural

components.

Compatibility

with Eurocode 1

Eurocode EN 1991-2:2003

Eurocode 1: Actions on structures - Part 2: Traffic loads on bridges

encompasses significant elements of the UIC 774-3 modelling approach

when evaluating the combined response of the structure and track to

variable actions. Limiting design criteria are the same as those

specified in the UIC 774-3 code meaning that Rail Track Analysis

software can be directly employed to meet Eurocode requirements.

Dependent software options

Because of the nature of the analysis

involved, the use of the Rail Track Analysis option

requires the following options to be accessible.

See also:

Find out more

|