|

|

|

Support Hinge Assemblies for the

Gateshead Millennium Bridge

Support Hinge Assemblies for the

Gateshead Millennium Bridge

|

|

"With

LUSAS, we optimised the distribution of material to give the

minimum weight and cost for the applied loading and got more

accurate answers than we would have done by other

means."

Phil

Snowsill, Senior Design Engineer, Kvaerner Markham |

|

|

|

Stress

and thermal analysis of a marine LNG loading arm

Stress

and thermal analysis of a marine LNG loading arm

|

| "By

employing LUSAS as an independent consultant Woodfield

Systems were not only able to confirm or adjust their

designs to ensure that they met the best possible design

conditions but were also able to provide complete confidence

to their client that the designs used would provide trouble

free operation, improve vessel turn-around and give

longevity of service." |

|

|

|

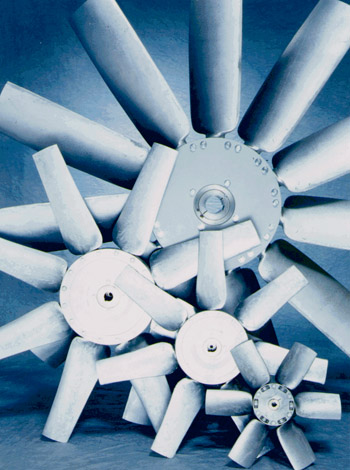

Design optimisation of an axial impeller hub

Design optimisation of an axial impeller hub

|

|

|

|

|

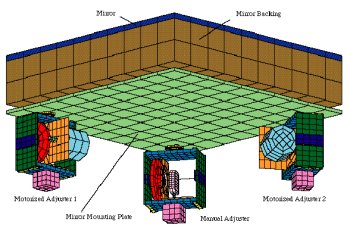

The design

and analysis of a laser mirror assembly

The design

and analysis of a laser mirror assembly

|

|

|

|

|

Optimising reciprocating gait

orthoses

Optimising reciprocating gait

orthoses

|

|

|

|

|

Enabling Rammer to hit harder

Enabling Rammer to hit harder

|

|

|

|

|

Innovative cable tie

design

Innovative cable tie

design

|

|

"The results produced from LUSAS

Analyst made it

possible for us to optimise the shape and dimensions of the cable tie cells to give the

performance we required for the specified loading conditions."

Andy Harsley, Technical

Director, Millepede Cable Ties

|

|

|

|

Contact analysis of artificial hip joint

components

Contact analysis of artificial hip joint

components

|

|

|

|

|

Faster vibration analysis of vehicle exhaust systems

Faster vibration analysis of vehicle exhaust systems

|

|

"Our evaluation of proposed new exhaust systems can

now be performed at least twice as fast as previous methods with greater accuracy also

being achieved."

Ian Rutherford, CAE Team Leader,

Arvin Exhaust R&D

|

|

|

|

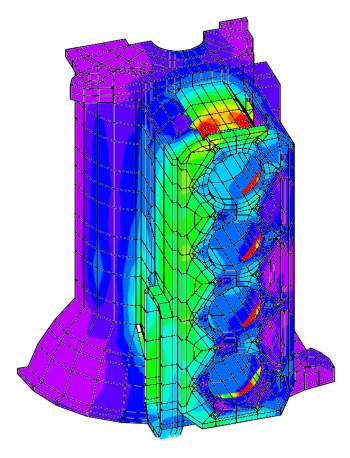

Engine analysis with

LUSAS and lasers

Engine analysis with

LUSAS and lasers

|

|

|

|

|

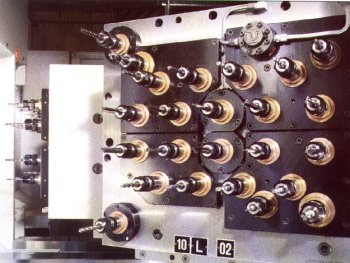

Automated dynamic

analysis of high speed drill spindles

Automated dynamic

analysis of high speed drill spindles

|

|

|

|

|

Innovative dynamometer

design

Innovative dynamometer

design

|

|

"We specialise in undertaking novel

engineering challenges so we need analysis software that provides reliable answers for any

type of analysis problem. LUSAS Analyst meets our needs in this respect and helps

to enhance our in-house design skills in a very cost-effective way".

Bill Coleman, Director at Design & Projects

|

|

|

|

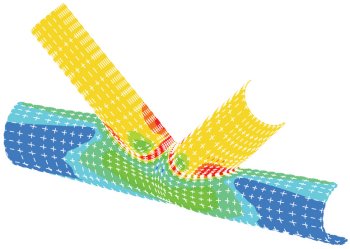

Offshore

centraliser design

Offshore

centraliser design

|

|

|

|

|

Fatigue analysis of tubular joints

with single-sided welds

Fatigue analysis of tubular joints

with single-sided welds

|

|

|

|

|

Pressure sensor for

monitoring mine safety

Pressure sensor for

monitoring mine safety

|

|

"The solutions to

these problems were far from obvious so we turned to FEA (Australia) Pty Ltd for advice.

The support we got was marvellous, with FEA coming up with some truly innovative solutions

and not resting until we had achieved our objective".

Ken McNabb, Mincad Systems

|

|