Software Option for

Plus versions

Heat of Hydration

The Heat of Hydration software option

allows for modelling the heat of hydration of concrete for a variety

of cement types. Effects due to the addition of fly ash and ground

granulated blast furnace slag can also be included. When used with the Nonlinear, Dynamic,

and Thermal software options the heat of concrete hydration can be

computed during a thermo-mechanical coupled analysis, with the

temperatures and degree of hydration used by a structural analysis to

determine a range of time and age-dependent effects.

In summary

LUSAS has long been

known for its advanced analysis capabilities, with a concrete cracking

and crushing material model developed over many years in collaboration

with top researchers in the field. Using the time-dependent creep and

shrinkage concrete material model allows for better assessment of

existing concrete structures and better predictions for concrete

placed quickly or adjacent to existing material.

For early age concrete, hygro-thermal

analyses allow the determination of heat of hydration across a body of

concrete, taking into account the availability of water for the

exothermic reaction with time, based on the concrete mix, shape,

exposed faces, insulated surfaces, environmental conditions etc. This

avoids the use of "typical" heat generation curves, although

these can still be drawn upon for comparison purposes.

When a hygro-thermal analysis is

coupled with a structural or "mechanical" analysis, the

cracking, crushing, creep and shrinkage capabilities of LUSAS can be

employed.This allows the determination of time- and age-dependent

deformations, stresses, crack-widths and more, working to - and beyond

the scope of - international Codes of Practice.

In detail

The Heat of Hydration

software option allows for 2D/3D modelling of coupled

thermal-mechanical behaviour of concrete due to its curing, and can

also allow for inclusion of formwork and other materials that might

act as insulators. The analysis results in thermally induced strains

that can be used to calculate crack widths and crack patterns. Heat of

Hydration analysis can be undertaken on mass or reinforced concrete

with detailed geometric modelling of reinforcement within the concrete

section being possible. The user has full control over the ambient and

casting temperatures at the start of the analysis and can also allow

for fluctuations in temperature. The internal inclusions of artificial

cooling or heating can be done at discrete locations in a 2D analysis

or along pipe lines in a 3D analysis. Results from LUSAS have been

validated against academic research and also against a third party

heat of hydration program.

|

Heat of hydration example

In the simplistic example shown

right, a cube of concrete is modelled with an 8x8x8 mesh of

HF8/HX8 elements and the concrete curing process is simulated.

Temperatures due to the heat of hydration can be obtained by

examining the hourly timestep results.

From the half-model results it

can be seen that the greatest temperature differential occurs at

34 hours.

A structural analysis using a

concrete cracking model based upon mechanical properties for

this time interval is then carried out and cracks can be

observed when differential expansion is enough to cause

principal stresses that lead to material failure.

|

|

|

Animation of

temperature change in mid-section of concrete block |

|

|

|

|

Crack planes at 35

hours |

Maximum principal

stresses at 35 hours |

Hygro-thermal analysis of a dam

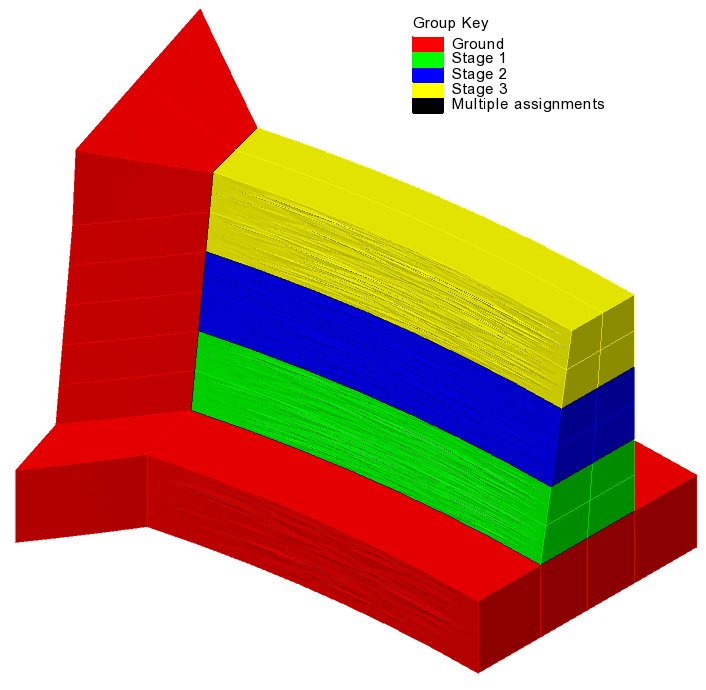

For the

staged construction of a dam, the effects that formwork and

environmental conditions have on the curing concrete can be examined

and The temperatures and stresses for each

time step for each construction stage can be obtained.:

|

|

|

| Staged

construction model |

Modelling

formwork during a stage |

|

|

|

| Temperature |

Stress |

|

|

Graphs of results such as the changing

of concrete temperature over time, shrinkage and thermal strains, or

water distribution, and more can be obtained:

And calculated crack widths for each

time step in each construction stage, both internally and externally,

can be visualised:

Dependent software options

Use of the Heat of Hydration software option

requires the following other software options to be accessible.

Find out more

|