LUSAS High Precision Moulding (HPM)

Consultancy Service

|

To accurately predict the distortion of laminated composite parts during manufacture

and provide reverse engineered surfaces to create "right first

time" tooling LUSAS offers a consultancy service

using its specialist LUSAS High Precision Moulding (HPM) software

product.

By using this service considerable savings can be made in

time to market, manufacturing time and costs are less, assembly

stresses are lowered, and the time-consuming fitting of any shims is eliminated.

|

|

Background

to Composites

Manufacture

During the cure of a composite part

residual stresses develop resulting in distortion of the component

from its moulded shape. This causes potential difficulties in its

use in product assembly. In aircraft airframe applications it is

estimated that a high percentage of the costs associated with

composite parts occur during the assembly process. This is mainly

due to the distortion of individual components and the time

associated with the rework and shimming processes required to

accommodate these distortions. As an example, an aircraft assembly

may require a significant amount of shimming to correct errors due

to component distortion. Historically trial and error tooling

changes have been carried out in order to try to achieve the desired

post-cure part shape but a more accurate and less ‘hit and miss’

method needed to be found. As a result, LUSAS High Precision

Moulding software was developed.

Modelling

Data defining the geometry of the

composite part and tool is first imported into LUSAS in either IGES or

STEP format. Once in, the HPM user interface (which has been designed

in collaboration with composite manufacturers), allows tooling

engineers to define all aspects of composite layup and cure simulation

modelling. High-performance linear and nonlinear elements are assigned

to the model along with boundary conditions, material properties and

layup orientation. Temperature profiles and analysis controls must

also be specified.

Several materials from commercial

suppliers are available. In the HPM material database the properties for

resins and fibres are stored separately to allow individual selection

according to use. Laminate properties are calculated from the resin

and fibre data properties using sophisticated micro-mechanics

equations. Weave construction details and fibre-volume fraction are

also defined via the HPM user interface. LUSAS HPM interfaces with FiberSim,

which gives seamless transfer of material information in XML format.

Linking of LUSAS HPM with CATIA Composites Design is possible via Simulayt’s

Composites

Link product. Visualisation of fibre direction and skew

angles allows for detailed checking of layup orientation. Nonlinear contact

algorithms can model slip and lift off between Part and Tool during

cure simulation.

|

|

|

|

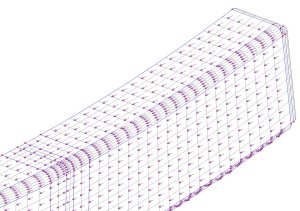

Visualisation

of layups |

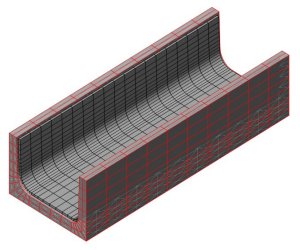

Contact

modelling of Part and Tool |

Analysis

A coupled thermal-mechanical analysis

is carried out in LUSAS to model thermal curing and calculation of

residual stress. The temperature and degree of cure throughout the

manufacturing process caused by the internal heat generation during

cure is calculated using a transient thermal analysis. This data is

then passed to a transient nonlinear stress analysis to compute the

deformations due to temperature change and chemical shrinkage. Results

are viewed in LUSAS HPM where displacements from the stress analysis

can be factored to provide updated tool geometry. The revised tooling

geometry calculated by the LUSAS HPM software can be exported in IGES

format for use directly in the CNC tool cutting environment and will,

in turn, produce a part that will cure into the correct shape for

intended assembly purposes.

Benefits in using

LUSAS HPM

By using LUSAS HPM software in the

design process competent design engineers can now extract master model

and tooling surfaces "right first time" ensuring that

correctly sized post-cure components are obtained without iterative

guesswork. As a result the product development cycle is significantly

improved. With the use of accurately calculated master and tooling

surfaces it is anticipated that the cost and time required to assemble

composite components could be greatly reduced. The ability to build

composite components accurately will also enable larger components to

be manufactured, reducing the part count and provide further savings

in manufacturing costs.

The revised tooling geometry

calculated by the LUSAS High Precision Moulding software can be

exported in IGES format for use directly in the CNC tool cutting

environment and will, in turn, produce a part that will cure into the

correct shape for intended assembly purposes.

Software Validation Modelling

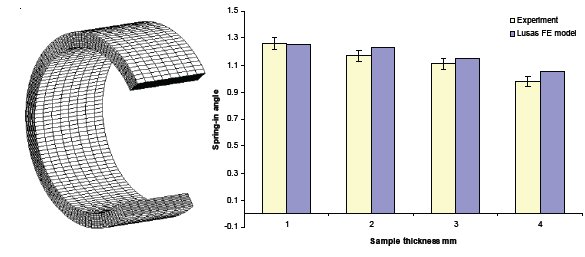

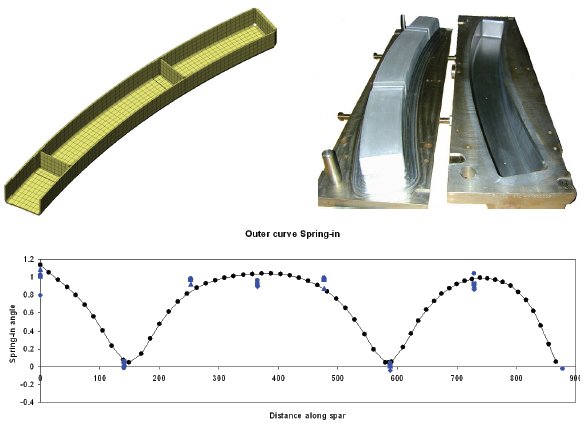

During the course of the development of

LUSAS HPM numerous models were created to validate results obtained

against manufactured items. LUSAS HPM results for models of C-shaped

laminates, exterior panels, cleated curved spars and curved spars with

ply-drop off all produced very good correlation with experimental and

manufactured test components.

C-Section model

showing good correlation of LUSAS and test results

C-Spar model and

tooling above spring-in results for outer curve of spar showing good

correlation between LUSAS and manufactured part.

Validation Components

The following images show just some of the

validation components used during the development of LUSAS HPM

software:

|

|

|

| Fan

cowl doors |

Exerior

panel |

Spar |

|