Case Study

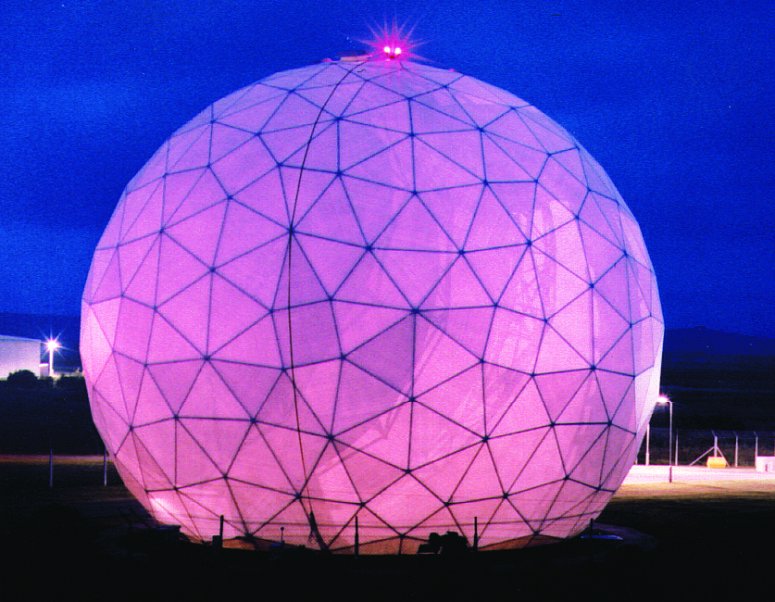

Composite Radomes

W & J Tod Ltd have been involved with fibre composites since 1948

and have a worldwide reputation for design and manufacture of large sonar acoustic

enclosures for ships and submarines. LUSAS Composite was used to analyse

high technology composite solutions for uses in Marine, Civil, Aerospace, Defence and Mass

Transport applications.

|

One such application

was a 3.7 metre diameter radome to suit a ship borne

antenna. The radome, when mounted on a ship superstructure, is subjected to shock loadings

greater than 15g as per MIL-S-901 and wind speeds in excess of 100 knots. The design

specifications require the radome mass to be kept to a minimum, the deflection from the

above combined loadings to be 50mm or less and all natural frequencies to be greater than

60 Hz.

The proposed construction comprises 29mm Nomex Aeroweb Honeycomb core clad both

sides with 1mm skins of biaxial glass cloth (with 0 & 90 degree fibres) laid in an

epoxy resin matrix, determined as much by the electrical performance requirements as by

the mechanical loadings. |

|

The model was constructed in semi-loof elements and a composite

data set was used to specify the material properties and lay up. The model was fixed at

the bottom edge and symmetric constraints were applied to the vertical plane edge. Several

loadcases were run to evaluate the effects of vertical and inclined plane shock loadings,

the natural frequency, and wind loadings as determined by Tod's own in-house software.

|

Other applications

LUSAS Composite has also been used for several other

composite application projects

at Tod's including:

- architectural domes for mosques

- helicopter radomes

- 2 metre diameter

butterfly valves for the power industry

- lightweight turbine blades

- composite pulley wheels

|

|

Other LUSAS Composite case

studies:

|

|

Software Information

|