Case Study

Share this

article

Design

and analysis

of above-ground full containment LNG storage tanks

-

Development of the world's

largest above ground LNG tank

-

Static, dynamic, thermal and

nonlinear analysis

-

Strict design requirements

met

KOGAS Gas Technology Corporation (KOGAS-Tech)

is using LUSAS Civil & Structural software to help

develop and continually improve its range of above ground full

containment Liquified Natural Gas tanks. With the assistance of

LUSAS engineering consultancy services LNG storage tank sizes of

140,000m3 were initially developed but now, using LUSAS

Civil & Structural, an above ground full containment

LNG tank with a capacity of 200,000m3 has been analysed

and optimised. When completed it became the

largest above ground full containment LNG storage tank in the

world.

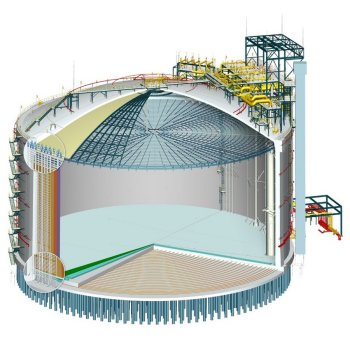

Tank development

Over

the years KOGAS-Tech has developed two distinct types of

above-ground post-tensioned concrete containment tanks. One

involves the use of a proprietary inner membrane system, and the

other comprises a steel nickel inner tank lining. Both are of a

140,000m3 capacity and have been installed at the

Pyeongtaek and Tongyeong facilities in South Korea. With the use of LUSAS software

KOGAS-Tech has now developed a 200,000m3 above ground

tank for the Pyeongtaek facility. Similar in nature to its smaller

brother it has a 37.6m high nickel steel inner tank of 84m

diameter insulated from a 86.4m inside diameter post-tensioned

concrete wall. The steel tank sits on a concrete base slab

supported by small diameter piles at close centres. The overall

tank height to the top of the roof slab is 52.8m.

|

Analyses undertaken

In analysing

and developing its range of tanks KOGAS-Tech performs

numerous finite element analyses with LUSAS including:

-

Static analysis

-

Wind loading

-

Modal and seismic analysis

-

Temperature modelling

-

Leakage modelling

-

Prestress / post-tensioning

-

Burn-out modelling

-

Relief valve heat flux modelling

-

Soil-structure interaction

|

|

Static

analysis

For static analysis, 2D axisymmetric solid element

and 3D shell element models are built and numerous static linear

analysis loadcases are defined for various parts of the structure

with the roof, the walls, the base slab etc being loaded

independently. Load combinations then allow the effects of the

multiple loadcases to be assessed.

Modal analysis

3D shell

element modelling and eigenvalue analysis of the LNG tank outer

shells and pressure relief platforms involves an examination of

both the uncoupled and coupled response of the two structures.

Lumped mass modelling is used for fluid/structure interaction of

the LNG and for soil/structure interaction of the pile

arrangements.

|

Wind load modelling

3D shell element

modelling is used to carry out wind load analysis of the LNG tank

outer shell. For this analysis, half-models can often be used due

symmetry of both tank geometry and loading. The wind load is

varied around the circumference of the outer walls using a Fourier

distribution providing a normal pressure on the forward face of

the structure and a suction to the rear face.

|

Seismic

analysis

Interactive

Modal Dynamics techniques are used in the calculation of the

dynamic seismic response. Operational Basis Earthquake (OBE) and

Safe Shutdown Earthquake analysis assessments are also run to

satisfy code requirements. The generated data from the structural

analysis is integrated to obtain base shear forces and bending

moments in the wall.

|

|

|

|

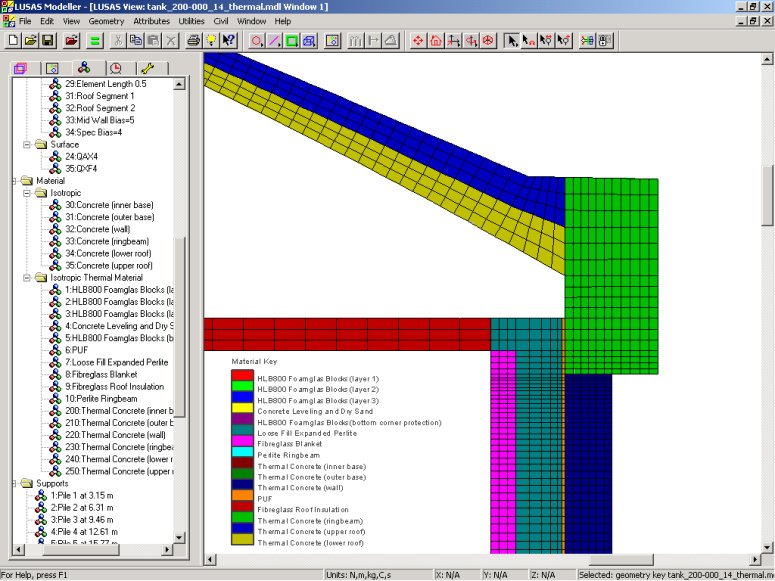

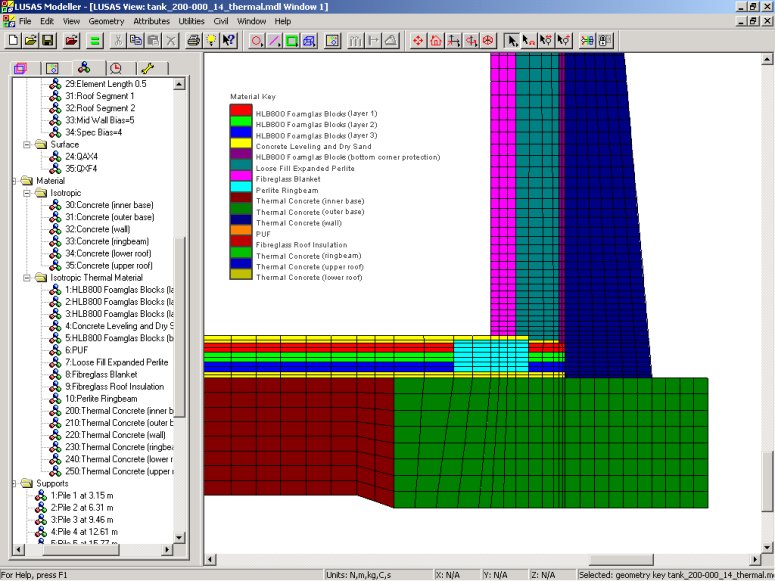

Thermal modelling

For thermal modelling, 2D

axisymmetric solid field and continuum elements are used and a

semi-coupled steady state thermal analyses of LNG tank outer walls

with insulation is performed. For this, an initial stress-free

temperature is applied to all elements, and combinations of

environmental conditions are considered for both the air and base

temperatures. Results plots of hoop stresses in the top and bottom

corners caused by a steady state thermal load are produced.

|

| Top corner

modelling |

| |

|

| Bottom corner

modelling |

Results plots of hoop stresses in the top and bottom

corners caused by a steady state thermal load are produced.

|

Leakage modelling

Leakage

modelling analysis investigates the effect of LNG spillage from

the inner steel tank onto the Polyurethane Foam (PUF) insulation

on the inside of the outer concrete tank at five different

heights. The tank insulation is assumed to have been completely

destroyed up to each level of the LNG under consideration. 2D

axisymmetric solid field and continuum elements are used to model

the tank outer walls and insulation down to the top of each

leakage level. A semi-coupled steady state thermal analysis is

carried out to assess the effects of the leakage.

|

|

|

Modelling

prestress tensioning

Large temporary

openings in the wall mean that it is necessary to limit the

effects of stress concentration caused by prestress forces.

Loadings for each set of cables, both horizontally and vertically,

are defined and assigned in separate load cases. These loadings

can then be combined in different ways to achieve the required

prestress sequence and/or loading pattern. Section slicing of the

model is used to obtain axial forces and bending moments in the

walls around the opening for selected load combinations.

|

|

Burn-out modelling

Modelling of a

burn-out scenario involves 2D axisymmetric solid field elements

and transient thermal analyses of the LNG tank outer walls. The

tank roof and insulation layers (except any PUF

layer), are assumed to have been destroyed, and are not included

in the analysis. Steady state conditions are initially applied for

a specified time. To model the burn-out situation, a temperature

load of a specified peak temperature reducing to -170°C over a

distance of 1.5m is moved down the inside of the tank at a

constant speed for the burn-out time under consideration.

|

Relief valve heat flux modelling

With

relief valve heat flux modelling, the tank bases are normally

excluded from an analysis because they are considered to be remote

from the heat flux loading. 3D solid field and continuum elements

are used for a semi-coupled transient thermal analyses of a

segment of an LNG tank.

An initial stress-free temperature is applied to all elements and

steady state conditions are established for an internal

temperature of –170°C and a specified mean annual external

temperature. A heat flux is then be applied to a specified region

on the top of the roof for the number of time steps under

consideration.

|

|

"Using LUSAS

allows us to continuously improve our analysis, research and

development capability especially in nonlinear analysis. With

LUSAS we can ensure that our range of LNG tank designs always meets

the strict design requirements of our clients."

Hag-Goo Sung, Civil

& Arch Dept Manager, KOGAS-Tech

Share this

article

Find out more

Other LUSAS Civil &

Structural case studies:

|