Additional Information

See the adjacent Software Information

links for general details regarding LUSAS software products and

options.

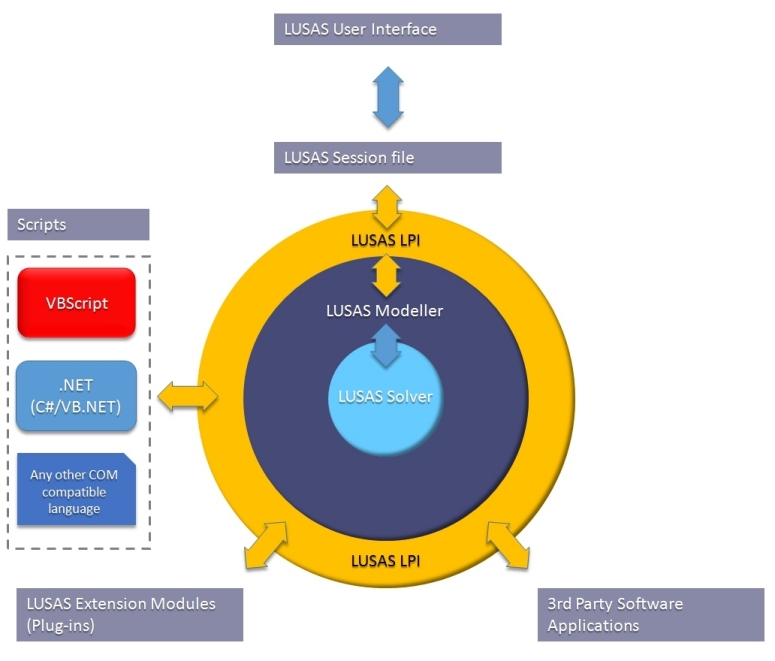

LUSAS Programmable Interface

The LUSAS Programmable Interface

(LPI) allows the customisation and automation of modelling and results

processing tasks and creation of user-defined menu items, dialogs and

toolbars as a means to access those user-defined resources. It can

also be used for transferring data between LUSAS and other software

applications, and to control other programs from within LUSAS Modeller,

or control LUSAS Modeller from other programs.

With LUSAS

LPI, any user can automate the creation of complete structures, either

in LUSAS or from third-party software, carrying out design checks,

optimising members and outputting graphs, spreadsheets of results and

custom reports. Because everything carried out by a user is recorded

in a LUSAS Modeller session file, anything that LUSAS can do can also

be controlled by another application via the LUSAS Programmable

Interface. This means that you can view and edit a recorded session,

parameterise those commands, turn them into sub-routines, add loops

and other functions to the scripts and create utilities, or a totally different

application or program - using the proven core technology of LUSAS.

LPI

languages and uses

By using any ActiveX compliant scripting language, such as VB.Net, C#, VBScript, C++, Python, Perl, JScript etc.

to access LUSAS facilities and functionality, you can:

- Create user-defined menu items, dialogs and toolbars

- Interrogate all aspects of a LUSAS model

- Customise modelling operations

- Create parameterised models

- Automate repetitive

tasks

- Import CAD geometry and properties

- Make direct links to Microsoft Word / Excel, or other programs for import or export of data

- Perform simple / codified design checks, and when used with automated iterative analysis, optimise structural member sizes and configurations, slab reinforcement quanties, etc.

- Control other programs from

LUSAS, and control LUSAS from other programs

LUSAS script files

In their simplest form

script files are used to store a sequence of LUSAS commands for later

playback. Some examples of use include the creation of start-up

templates to pre-load the Attributes Treeview of the LUSAS Modeller

user interface with selected attributes for a particular analysis; the

setting of default mesh or material types, or preferred colour

schemes; or defining specific model orientations for use when saving

model views for use in reports.

When LUSAS is run, a

session file is created recording each step of the model generation in

Visual Basic Script (.VBS) - one of the most commonly used and easily

understood languages. Editing of a session file can be used to define

a similar model with new parameters. When the script is re-run in

LUSAS, a new user-defined model can be easily and rapidly generated

from the parameters defined. A Macro Recorder facility in LUSAS also

provides the means to record a sub-set of commands for a task, for

saving and re-use. User-generated scripts can be controlled by

creating dialogs that may include parametric variables, check boxes,

drop-downs etc.

Varied uses of scripts

include reading of geometric data, such as column dimensions, section

properties and span lengths / storey heights etc., from a spreadsheet

to automatically build multi-span bridge or building models; rapid

generation of parametrically-idealised wind farm base structures, or

for automating the creation of numerous load combinations and

envelopes; and for slicing through a model to create results for

multiple loadcases, which can be automatically plotted on graphs and

in reports.

A set of example

scripts are provided in LUSAS to assist in the understanding of

standard concepts including file handling, how to access LUSAS

geometry / attribute data, and how to import / export data from / to

Microsoft Word or Excel, or other programs.

Visual Basic, as well

as JScript, Python and Perl are known as interpreted languages -

meaning that there is no need for compilers to be used.

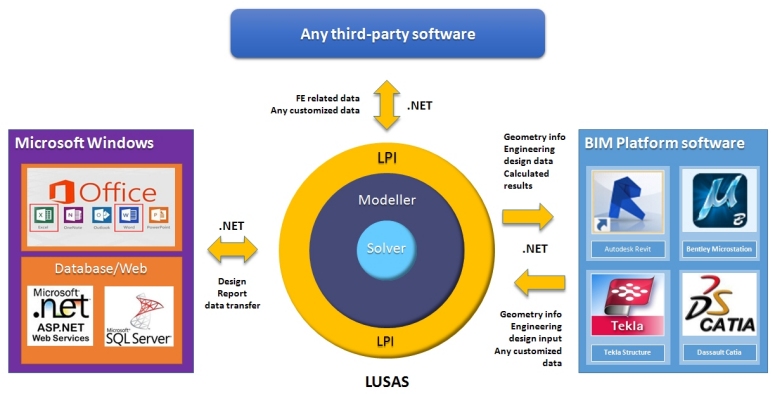

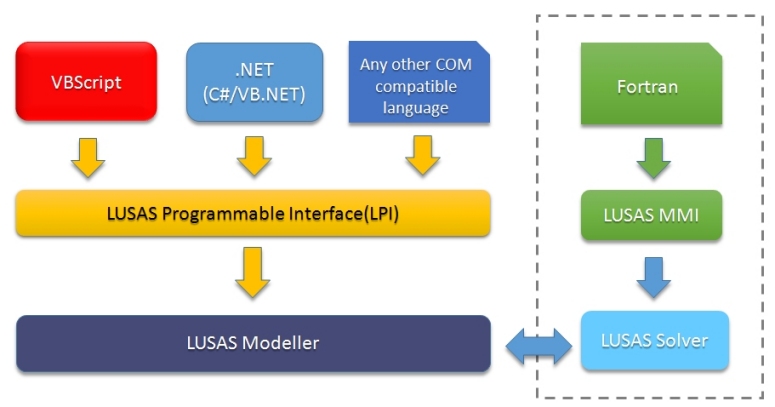

Component technology

| The

LUSAS Programmable Interface allows interfacing with other

compatible Windows programs through a Component Object Model

(COM) interface. This defines a set of rules by which two

programs can communicate and allows controlling those programs

as if they were part of LUSAS Modeller. LUSAS can also be used

as a component of another system (running transparently if

required) providing modelling capabilities, analysis solutions

and results viewing and processing options for that

application.

Examples

include controlling external programs for inputting data into

LUSAS, such as importing CAD geometry and properties for data

sharing, as well as for exporting data for post-processing

uses, such as exporting results into cells in a spreadsheet

for additional calculations to be carried out. Typical uses of

LUSAS as a component of another system include using LUSAS as

a part of an automated BIM design system to allow customised

design checks to be made within LUSAS before saving selected

model / results data in a BIM platform, such as REVIT or

Bentley. |

LUSAS being used

to provide results for a third-party application. |

This more advanced

customisation and use of LUSAS can make use of VB.NET, which (along

with C# and C++ languages) requires compiling before use. However, the

main benefit of using these languages over interpreted languages, such

as VB Scripting, is that they are more powerful and provide standard

plug-ins, controls and libraries of subroutines - avoiding the need to

write them in-house.

Programmable Interface Architecture

LUSAS provides a .NET

project template (also known as a plug-in), which can be customised by

users to ‘interrogate’ LUSAS Modeller. This allows the exchange of

design report data with particular Microsoft applications; the

exchange of geometry design and results data with BIM platform

software; and exchange of FE related and any customised data with

third-party software applications.

Overall, LUSAS provides

a rich programmable interface, with hundreds of programming interfaces

(each having associated subroutines) that provide an LPI user with

total control over all aspects of a LUSAS model - and not just for the

attribute and geometric data. As an example, it is possible to use the

interfaces to query a model and extract element results, perform

design code-related calculations, and then either export those results

into a spreadsheet format, or to make them available within LUSAS

Modeller to enable contouring of those results using standard results

processing and viewing facilities.

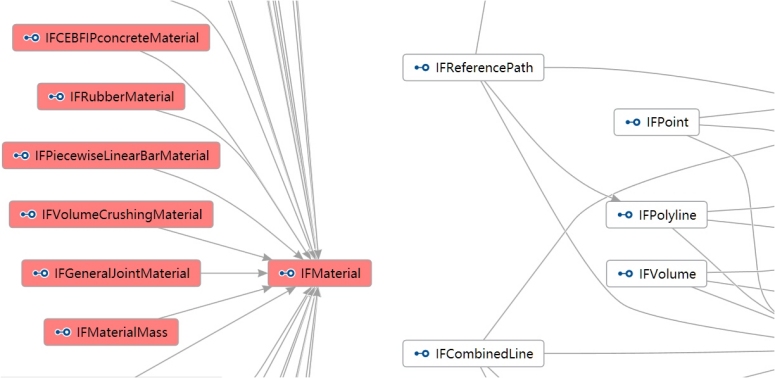

LUSAS Material Model

Interface

In addition to the

accessing and customising LUSAS Modeller via the LUSAS Programmable

Interface, user-defined material models (written in Fortran) can be

compiled and built into a customised LUSAS Solver executable by using

the LUSAS Material Model Interface (LUSAS MMI).

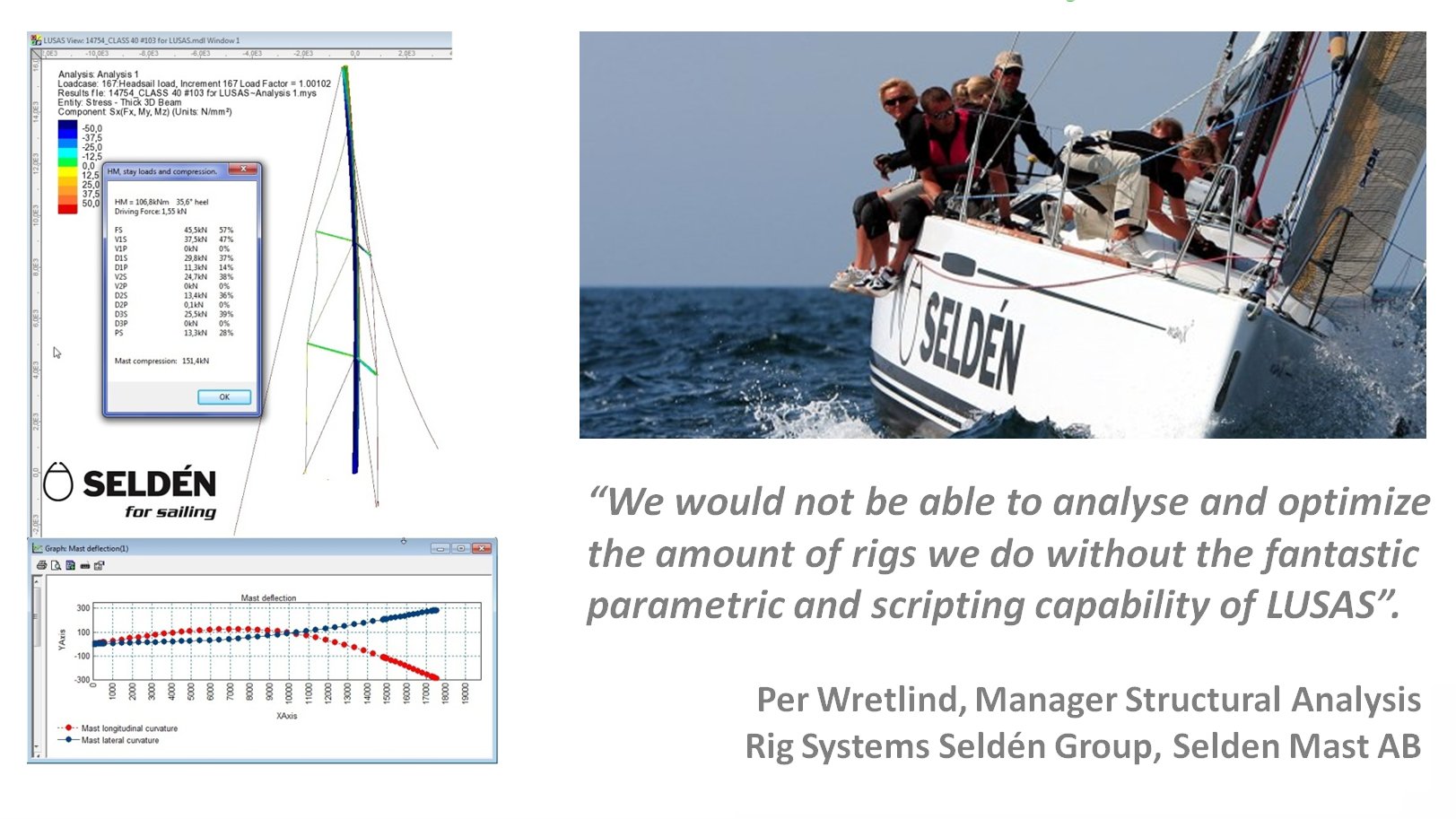

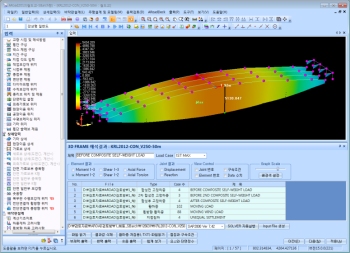

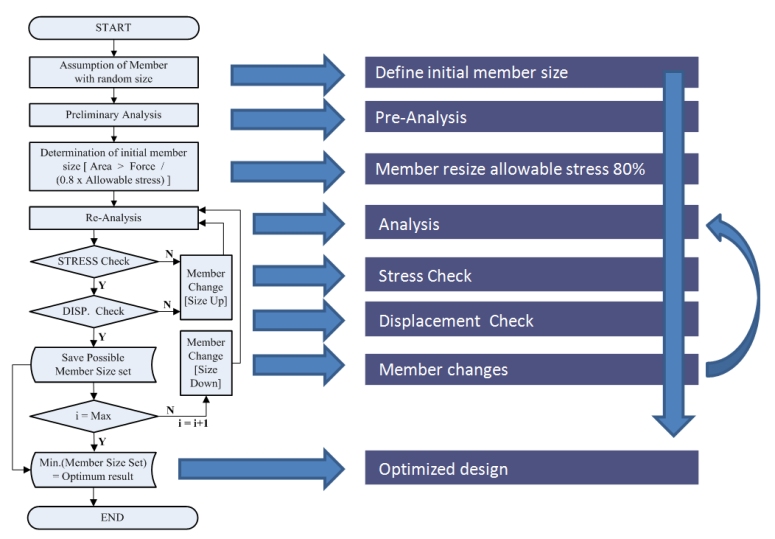

Case study: Optimised steel dome

modelling

FEA Korea wrote VB scripts to

automatically model and optimise the members in a chosen steelwork

dome arrangement on behalf of its client, Samsung Engineering and

Construction. Roof types supported by the software wizard included a

flat truss roof, a vaulted roof, and also circular, oblate, and

elliptical domes.

Span lengths and dimensional data are

user-defined for a chosen roof type. A preliminary LUSAS analysis is

used to assign initial section properties for each member based upon a

specified initial stress ratio. Optimisation target parameters are

then defined. From user-defined values, loadings appropriate to the

chosen design code are created and applied automatically to the

relevant parts of the model. A stress check and a displacement check

then take place to see if member sizes need to be increased from their

initial sizes, prior to saving the resulting member sizes as a

possible set for use. An iterative procedure than checks to see if any

members can be reduced in size before saving a set of minimum member

sizes as an optimum result.

For serviceability checks a model is

automatically converted into one with elements suitable for either an

eigen buckling analysis where buckling checks can be carried out for

distributed, concentrated or user-defined loadings, or for one

suitable for either a material, geometric, or material and geometric

nonlinear analysis. Graphs, diagram plots, and reporting can be output

for code-checked results, deflections, connections and many other

results quantities.

Other case studies

Other case studies on which LUSAS

scripting has been used to carry out automation and customisation

include:

Associated webinar

Back to Top

|

|

Software Information

|