Case Study

Stress

and thermal analysis of the 'Muela Dam, Lesotho

- Linear, thermal and nonlinear

analysis

- Crack propagation evaluation

- Dam stability and optimum

curvature proved

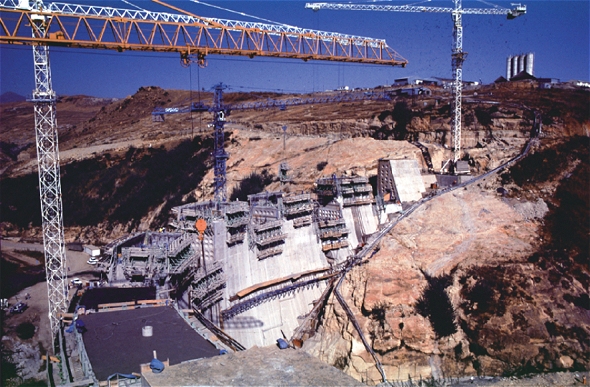

LUSAS Civil & Structural analysis software has been used by

consulting engineers Mott MacDonald

in conjunction with FEA's consultancy services department to prove the stability and

optimum curvature and profile of the 'Muela Dam, part of the Lesotho Highlands Water

Project. The 55m high dam with a crest length of 200m forms the tailpond of the 'Muela

hydropower project.

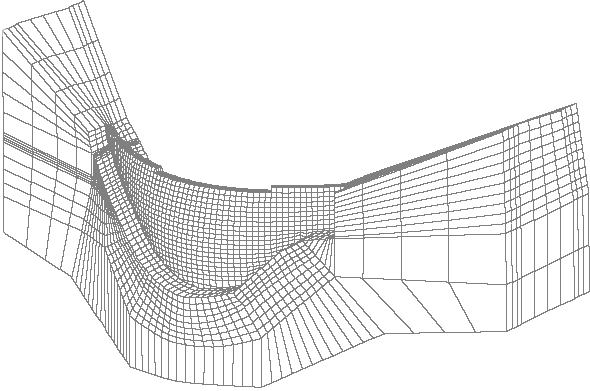

A full 3D model of the dam and its rock foundation was defined in LUSAS Civil & Structural using 8-noded enhanced strain elements with 4

elements across the width of the dam and at 2.5m height intervals. In all 9528 elements

were used to define the dam model including 5880 elements in the rock foundation.

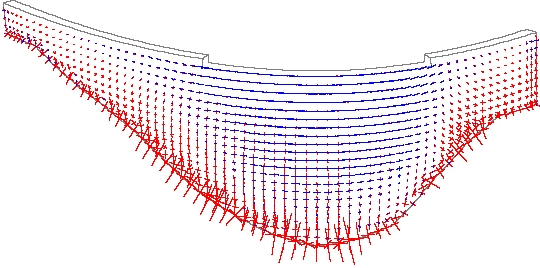

The linear elastic analysis of the dam covered a wide

range of different load cases, including reservoir full and empty, silt and temperature

effects. In view of the low seismicity of the area, dynamic analysis of earthquake

loadings was not considered justified. However, the influence of earthquake loadings was

examined by the pseudo-static method, on the basis of a ground acceleration of 0.2g. This

acceleration was distributed throughout the structure on the basis of a damping ratio of

3.

Monthly mean temperatures at 'Muela can range between 6 and 19

degrees centigrade in an average year and as low as 3 degrees centigrade in a cold year.

In addition, the transfer water from the Katse reservoir was expected to be at about 6

degrees. A thermal analysis was carried out using Schmidts method to

establish the in-service temperature gradients within the dam and also the requirements

for artificial cooling, on the basis of Fouriers's law of unsteady heat flow through

solids and using a step-by-step integration process. This analysis covered the initial

placing temperature of the concrete, variations in air and reservoir water temperatures,

heat gain in adjacent concrete pours, solar gain, lift height and intervals and heat of

hydration.

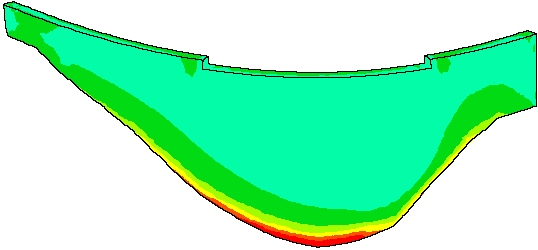

The linear analyses under the various load cases

indicated maximum compressive stress of 6N/mm2 under normal conditions, well within the

maximum permissible stress of 8N/mm2 after allowing a safety factor of 3 on the

characteristic concrete strength of 25N/mm2. Tensile stresses also occurred under several

load cases, primarily at the upstream heel. The extent of distribution of tensile stresses

is more critical than the actual magnitude at any particular node and this was examined

further by a nonlinear 'no tension' analysis where a crack was allowed to propagate at

areas of tensile stresses. This was carried out for the most critical load case of

reservoir full and average-year winter temperatures and with uplift under the reservoir

head applied at the crack. This 'no tension' analysis indicated that the maximum crack

propagation would be solely over the upstream quarter of the dam/foundation contact, which

is acceptable.

Find out more

Other LUSAS Civil &

Structural case studies:

|