Case Study

Design and analysis of Gota Tunnel (Götatunneln)

- Detailed 3D modelling of large concrete box tunnel structure

- Creation of customised scripts for results processing

- Smart load combinations and slice sectioning of model

Skanska Teknik AB, of Sweden,

used LUSAS Civil & Structural to help analyse and design a 128m long, reinforced concrete

section of tunnel which carries road 45 beneath the city of Gothenburg. Customised scripts

were developed by LUSAS Consultancy Services for specific use on the project to automate

the results processing operations, produce graphs and screen plots, and output results

data for spreadsheet calculations of reinforcement quantities using Skanska Teknik

AB’s own in-house software.

Overview

The main tunnel design contract

was split into three with the Western cut-and-cover

section at Järntorget being designed by Skanska

Teknik AB. This contract comprised a 96m open cross-section, a 128m long twin

reinforced concrete box tunnel with an integral access ramp structure, ventilation shaft

and 30m high chimney, and a 276m long twin-box tunnel. The 128m long access ramp/tunnel

structure carries two carriageways of traffic in both directions and is also subject to

vehicle loading on its roof due to a car park and access roads above. The tunnel walls and

roof slab are 1m thick. The floor slab varies in thickness from 0.8 to 1.5m. In all,

nearly 1000 piles support the structure.

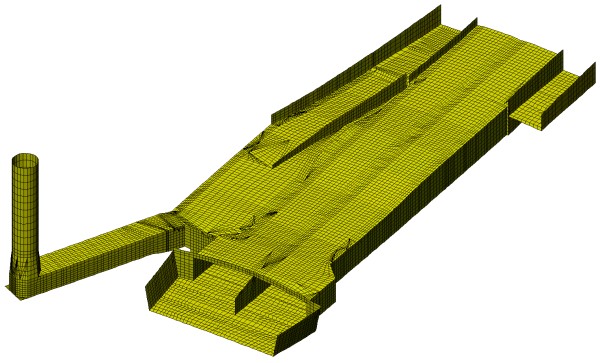

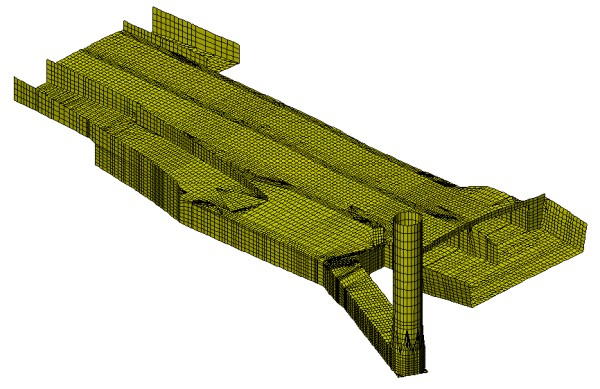

Modelling in LUSAS

Almost 22,000 elements were used to model the complex tunnel structure to the required

level of detail. Thick shell elements - used so that out-of-plane shears could be

extracted - modelled the concrete structure. Joint elements modelled the end bearing and

frictional piled supports.

Load cases applied to the model included:

- Differential settlement, modelled as a sine curve along and across the tunnel centre

line.

- Temperature gradient and shrinkage

- Soil and water pressure

- Varying water level

- Vehicle loads - manually evaluated

ULS

and SLS Load Combinations

In LUSAS, the Smart Combinations facility can automatically generate maximum and

minimum load combinations for any selected design code from applied loadings and allows

for adverse or relieving effects. From these load combinations, envelope, contour and

deflected shape plots and results graphs can be readily obtained for any loadcase under

consideration. However, on this particular project the Smart Combinations facility was

combined with customised scripts written by LUSAS Consultancy Services to automate the

output of the results processing and produce results for additional spreadsheet

calculations.

|

|

|

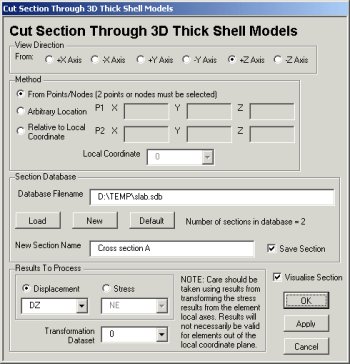

Scripting in LUSAS

Of many custom scripts written, a model sectioning tool was developed to allow a cut

section to be taken between selected points, nodes or at specified coordinates on the

model. The location of the section could then be stored and named in a database for future

use. Chosen results of interest for the selected loadcase were then automatically plotted

on a corresponding graph. In this way plots of either stress, shear or displacement could

be readily obtained for each active loadcase allowing rapid assessment of the structure

along its length. By changing the active loadcase and re-selecting the same cut name from

the database a whole series of results for the many load cases and load combinations could

be obtained.

To calculate reinforcement quantities Skanska

Teknik AB used stress resultants calculated by LUSAS in its own in-house Microsoft

Excel spreadsheets. A load combination listing script in LUSAS exported basic and smart

load combination definitions and envelopes (including load cases used and load factors

applied) to a spreadsheet for quality assurance, and cross-checking purposes.

|

|

Benefits of using LUSAS

Mathias Uhlán, Structural Engineer at Skanska

Teknik AB said: ‘Since the geometry was so complicated it

would have been difficult to model the tunnel in 2D, and in order to do so a far more

conservative approach would have had to be taken. But by using a 3D

LUSAS model we could slice

sections through the model and easily plot the results we wanted at our chosen

locations.’

He continues:

"Ultimately, the main benefit in using LUSAS for this project was to

be able to take into account the complex geometry of the structure and to

get all of the results we required from the one model."

"...the

main benefit in using LUSAS for this project was to be able to take into

account the complex geometry of the structure and to get all of the

results we required from the one model." Mathias

Uhlán, Skanska Teknik AB

Find out more

Other LUSAS Civil &

Structural case studies:

|

|

Software Information

|