Case

Study Case

Study

Share this

article

Erection engineering

analysis of a replacement roof for the London Olympic Stadium

-

Erection

engineering analysis for what is believed to be the longest

cantilevered roof in the world

-

Modelling and

analysis of compression truss, columns, cable-net and roof

steelwork using nonlinear methods

-

Structural members of the permanent works and stability of the

structure during roof installation confirmed adequate

COWI (previously Flint & Neill

Limited) was appointed by principal contractor Balfour Beatty to

provide erection engineering services for the deconstruction of the

original roof of the London Olympic Stadium and subsequent

construction of a new long-span replacement roof for what is now

called the London Stadium. This work was required as part of

transformation works carried out on behalf of the London Legacy

Development Corporation. LUSAS was subcontracted by COWI to perform

independent checking of the various deconstruction and construction

stages involved, and confirmed the adequacy of the structural

members which formed the permanent works and global stability of the

structure under applied loads.

Overview

Subsequent conversion of the stadium

into a mixed-use venue required a new roof to be constructed. COWI

used its own in-house package NODLE to carry out a deconstruction

analysis of the original roof involving dismantling of the lighting

towers, removal of the membrane, and lowering of the cable net, and

roof deconstruction was completed in February 2014. Whilst LUSAS also

carried its own deconstruction analysis of the original roof, this

case study is limited to the erection engineering analysis performed

for the replacement structure.

|

|

|

|

London Olympic

stadium as originally constructed.

|

Original stadium

roof.

|

|

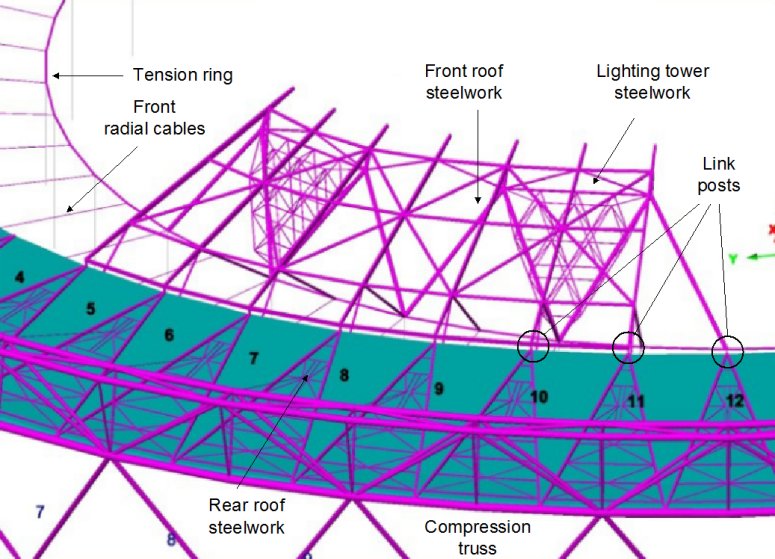

The new roof

consists of a primary cable net structure supporting

articulated steel trusses which create the upper roof

profile and in turn support the roof coverings. The existing

compression truss connections and raked V-columns required

strengthening to bear the increased loading from the new

roof structure which, at approximately 48,000 square metres,

and with a maximum cantilevered length of 84m, is twice the

area and three times the span of the original.

The

construction sequence and hence modelling and analysis

requirements for the new roof took place in

three distinct phases:

-

Phase

1: V-column strengthening / replacement

-

Phase

2: Installation of cable net

-

Phase

3: Construction of rear and front roof

|

|

|

New and

original roof configuration.

|

|

|

|

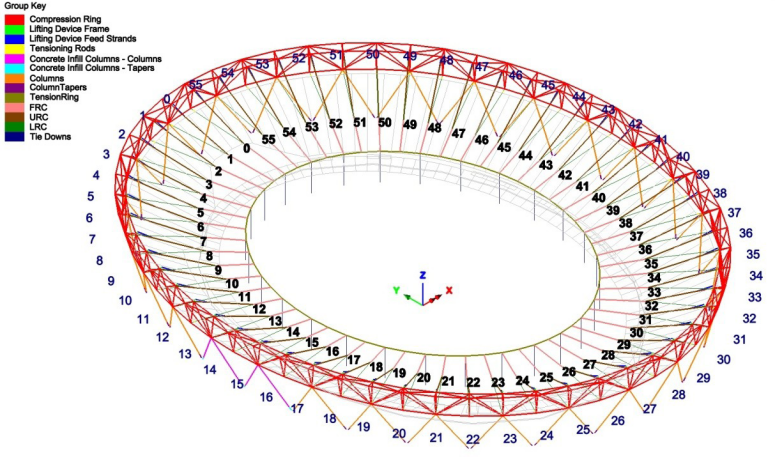

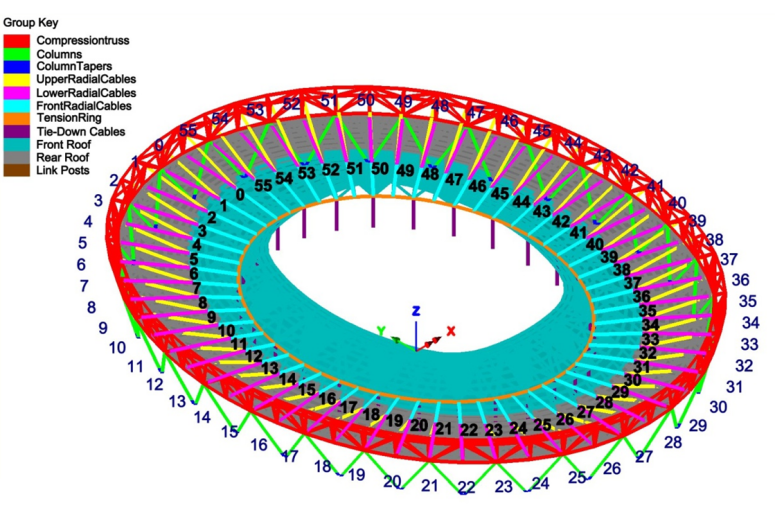

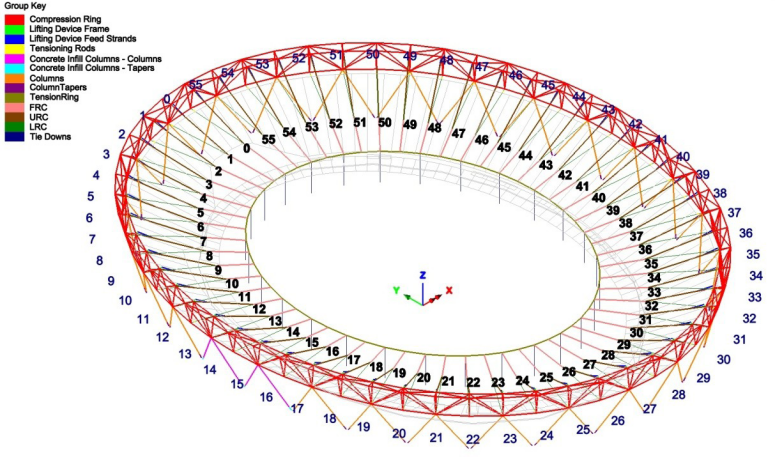

Key components

of the new London Stadium roof.

|

Overall analysis

and modelling requirements

LUSAS was required to verify the

adequacy of the global structure and structural members at critical stages of construction. This involved:

-

Ensuring that the

starting LUSAS finite

element model (used in a reverse analysis) satisfied the reference stressed state reflecting the permanent condition of the

completed stadium roof.

-

Analysing the staged replacement of

the V-columns and providing an envelope of member forces on connections for

use and verification of local connections by others.

-

Analysing the roof structure at various

stages in order to verify that all structural

members designed for permanent condition were adequate for the

proposed construction methodology and that structural stability

was

maintained throughout.

-

Providing internal forces, enveloped

erection force effects and utilisation factors for critical

members in the roof members, cables, compression truss and column structure

for various stages of the construction process; and displacements at

key locations for various stages.

In all analysis cases, the LUSAS models

generated were subjected to loads based on British Standards as

appropriate to the structure and its location. Generally:

-

The compression truss and columns of

the stadium were modelled and analysed using appropriate large

displacement nonlinear methods, using thick nonlinear beam elements

in which shear deformations were included.

-

Cables were modelled using multiple

elements to distribute self-weight loading along their lengths,

and to include

the geometrically nonlinear effects of the cables sagging. Cable

element end releases permitted free rotation at the cable

connections, and a low bending stiffness along with using

nonlinear joints at their end allowed the cables to behave as

tension-only members.

-

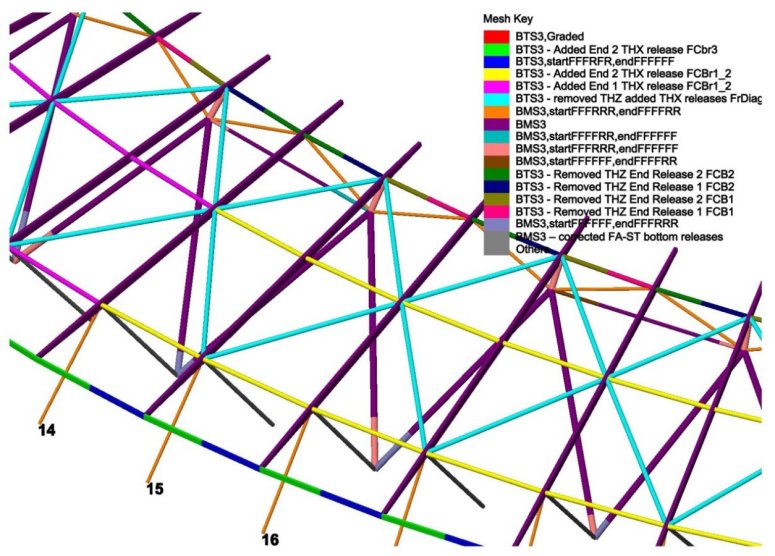

Beam end releases were used to

model the individual connection requirements for each

member.

-

For modelling and

analysis of all construction phases extensive use was made of

LUSAS Visual Basic scripting facilities to automate procedures

such as loading assignment, creation of load combinations, and

the carrying out of design checks.

Phase 1

- V-column

strengthening / replacement

|

This required

the strengthening and replacement of the

original raked

V-columns.

Replacement of

the original raked V-columns was simulated using a

geometrically nonlinear static analysis to take into account

the effects of the changes in position and angle between

column and truss members. To model each column

replacement, first, the

support at the bottom of the adjacent column (which was not

being removed) was changed to be pinned and the framing-in

column removed. Then, a total imposed displacement load was

applied to the upper node of the removed column to return the deformed mesh to its

original position (modelling the jacking-up process). A new

column was then activated with pinned supports. Removal of jacking

simply required removal of the imposed displacement, before

permanent loading only was re-applied to reinstate the original loading conditions.

Member

resistances/utilisations were calculated using

BS5950-1:2000 for all members in the compression truss using

the appropriate section properties. To do so, two global models were

developed; one having diagonal members of the compression ring pinned about both axes of rotation

such that end moments would be zero, and the other with diagonal and

radial members pinned about one axis and rigidly fixed about the second.

For summarising truss connection force envelopes, the fully pinned

model was used, but for all other results the model with one

fixed end condition was used.

Results

obtained

Checks carried

out for Phase 1 included those

appropriate for shear, moments, axial tension/compression

and combined effects as appropriate. Results plots and

spreadsheets of utilisation factors for all truss members

and loadcase combinations based on design code were obtained

and confirmed the adequacy of the permanent

works and the stability of the structure during column

replacement.

|

London

Olympic Stadium as built, in 2012

|

Phase 2

- Installation of cable-net

The tension ring was

lifted into place by using strand jacks installed on the inner top

chord of the compression truss. This was followed by installing and

stressing the lower radial cables using hydraulic jacks. Temporary

tie-downs were installed to pull the tension ring into a predefined

geometry.

|

|

|

LUSAS model

for Phase 2 analysis. |

Modelling

and analysis

The initial lay-out positions on the

ground for the lug plates and tension ring connectors were one of

many items to be

determined as part of the Phase 2 analyses. From inspection

of the roof geometry and member connections to be used when

modelling the construction of the rear roof (Phase 3A), it was seen that a

reverse construction (deconstruction) modelling approach could be

taken, and this was critical to being able to start the analyses

from the supplied reference condition for the final form of the

structure. As a result, the lifting and stressing analysis was

therefore carried out in a reverse order starting from the end

of the

stressing phase, and modelling the lowering of the cable net system

until the cable-net lug plates and tension ring connectors had come

to rest on the seating tiers and the ground. Joint elements with

nonlinear smooth contact properties were used at the intermediate

nodes and tension ring nodes to model contact in a direction normal

to the ground and upper or lower seating tiers as appropriate.

The

bases of the V-columns were

modelled as pinned during the stressing phases. At the end of the stressing phase

the bolts at the bases of the columns were fully tightened and these

were modelled as fully fixed in translation and rotation from the

end of the stressing phase and during the tying down and roof

steelwork erection phases. The Upper Radial Cables (URC), Lower Radial

Cables (LRC), Front Radial Cables (FRC), tension ring and lifting

device feed strands were modelled in LUSAS using multiple thick

nonlinear beam elements with end release to allow free rotation at

the cable connections. Cables were modelled with multiple

elements to include

the geometrically nonlinear effects of the cables sagging. Lug plates at

intermediate nodes and the tension ring connectors were modelled as

a single node with their self weight applied as a concentrated point

loading at each appropriate location. Tie-downs were modelled using

a single bar element per tie-down. Tie downs (without any anchorage)

were to be allowed to lift with the tension ring, and as a result

the weight of these tie downs and their connections was modelled as

a concentrated load at each tie down location. For anchored

tie-downs, the weight of each kentledge was applied as a

concentrated load at the supported point at the tie down location in

the model, to allow reactions to be checked more easily.

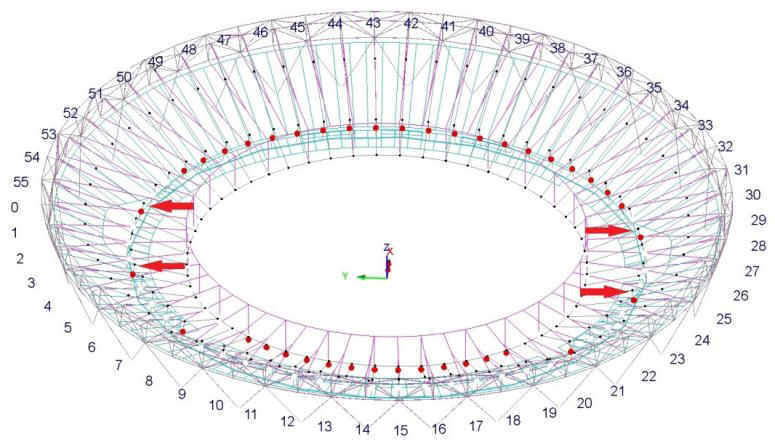

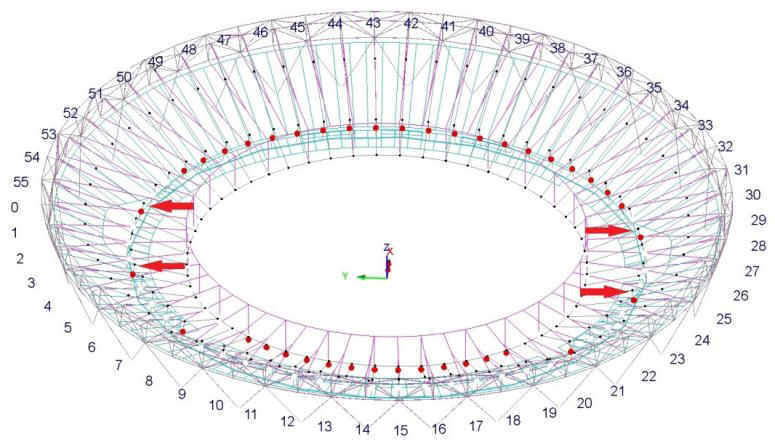

|

| Cable-net

lift (red circles show contact locations). |

| |

|

| Animation

of cable-net

lift: aerial view. |

| |

|

| Animation

of cable-net

lift: view along y-axis. |

| |

|

| Isolated

animation of cable-net lifting at grid line 0. |

| |

|

| Cable-net installation

and tie-down complete.

|

Results obtained

For Phase 2, LUSAS provided the

following results from global models of the new roof for various

stages of the cable-net installation process:

- Cable forces and angles

- Utilisation factors for all truss members, columns and cables

- Forces applied indirectly to the

seating tiers

- Feed strand lengths during the

lifting phase

- Verification of the stress free

layout geometry of the cables, lug-plates and tension ring

- "Lift-off" position of

each lug plate and ring cable connector

- Verification of the geometry at

the end of the lifting, stressing and tying down phases

- Verification of the target

geometry and tie-down tensions at the end of tie-down

- Verification that the safety

factor against kentledge lift-off was adequate

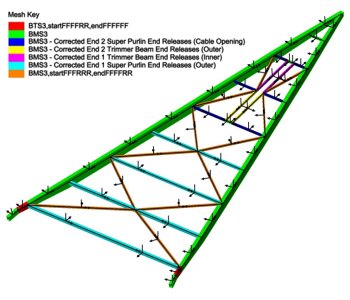

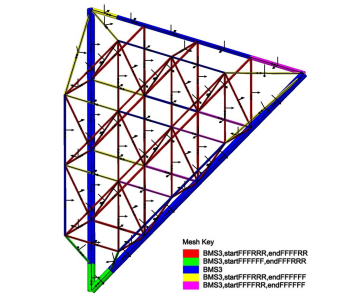

Phase 3

- Construction of rear and front roof

In

Phase 3, roof erection started with the installation of the rear

roof and on two construction fronts, with the installation of

the rear roof cladding following one-eighth behind the

construction fronts. Once the main steelwork and three-quarters

of the rear roof was clad the erection of the front roof

started, with its associated lighting towers and cladding

following a similar sequence. To aid the erection process to

achieve the target roof configuration, temporary link posts were

installed at the apex of the rear roof back diagonal beams where

the rear and front roof were temporarily linked. The outer ends

of the front radial beams were connected to these to allow the

front roof to be held as further elements were installed.

Using LUSAS Civil & Structural a

geometrically nonlinear static forward analysis was carried out to take into

account the effects of the changes in position and angle between

members and to account for nonlinear effects in cables. The column, truss

and cable net configuration was inherited from the Phase 2 analysis, so that identical stressing and tie-down stages

could be incorporated into the Phase 3 analyses, and additional steelwork and cladding of the

front roof was

incorporated into the analysis.

When modelling in

LUSAS, the link posts were considered to be very stiff to obtain the

forces-moments in these members and ensure that the correct relative positions of the rear and

front roofs were maintained. These link posts, along with the tie-down

cables installed in Phase 2, were removed once the roof erection

process was complete. By using a forward construction analysis as

opposed to a reverse one, after

removing the link posts and tie downs the circumferential beams of the front

roof steelwork would be in axial compression on completion, and a

predicted constructed geometry would be obtained.

|

|

|

Modelling of

rear and front roof erection sequences.

|

| |

|

| View

of rear and front roofs showing upper, lower and front

radial cables connecting to lug plates and tension ring. |

Results obtained

For Phase 3, numerous results from

global LUSAS models of the new roof were obtained to check the various

stages of the roof steelwork installation process. These included:

-

Utilisation factors for

all truss members, columns, cables and roof steelwork

-

Link post forces and moments under

SLS and ULS loading combinations for the whole erection of the front

roof

-

Connection forces for the connection

of the rear roof back diagonal beams to the compression truss,

which are affected by the temporary connection of the front roof to the

rear roof through the link posts during the erection of the front

roof

-

Verification of the geometry at the

end of each notional erection stage

-

Estimation of the lack of fit

adjustment to the circumferential members

-

Verification that the kentledge, used

to hold down the tension ring,

would not lift-off during the erection process

|

|

|

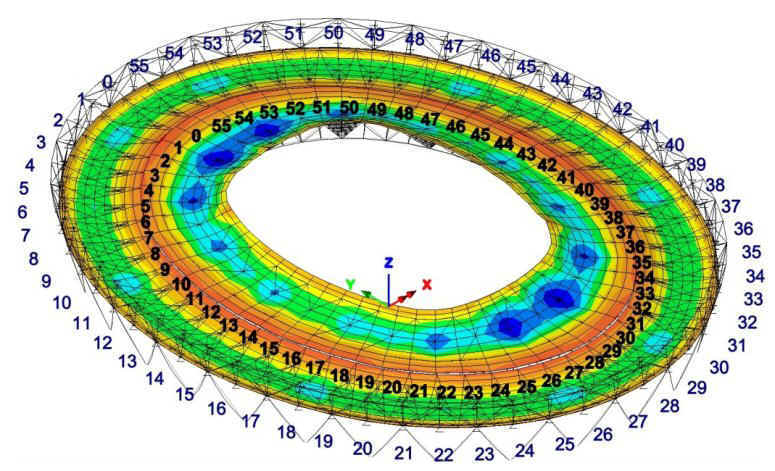

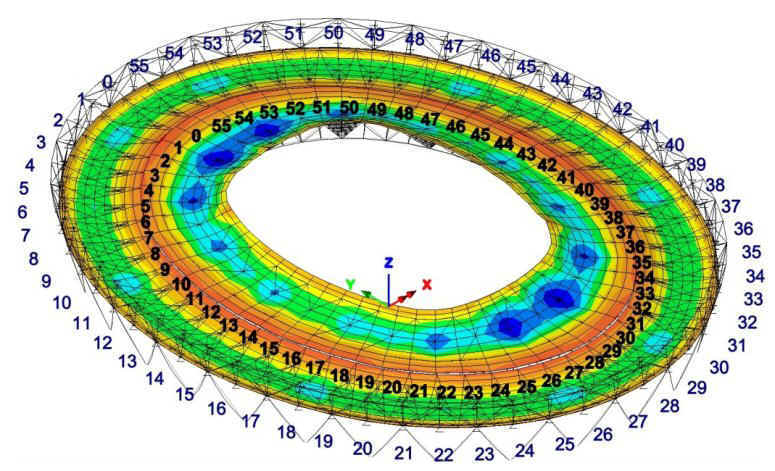

Vertical displacement

contours for final roof position (for cladding speed case

1). |

|

|

|

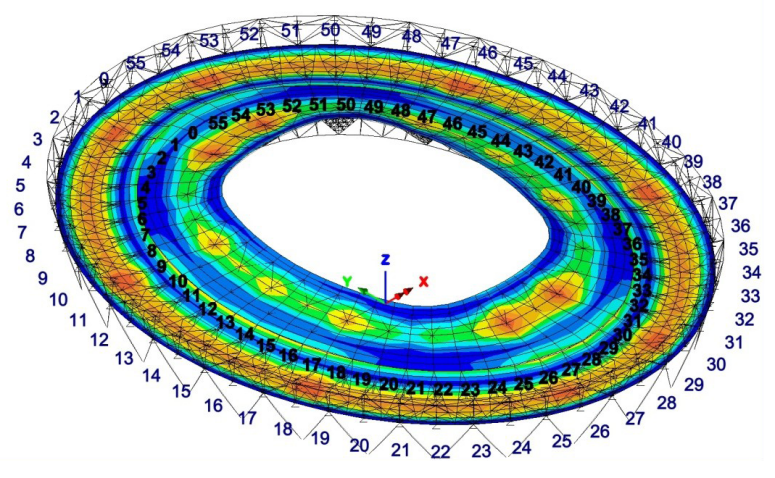

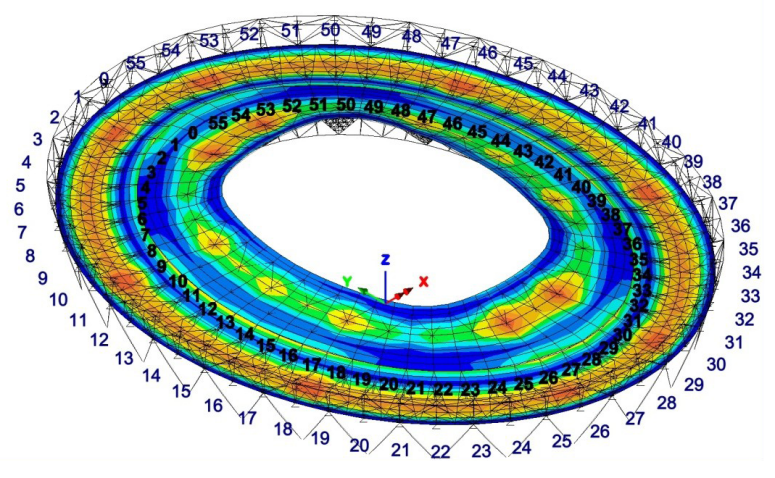

Resultant

displacement contours for final roof position (for cladding speed case

1). |

Summary

The transformation of the former London

Olympic Stadium into what is now known as the London Stadium is now

complete, and its replacement roof is believed to be the longest

cantilevered roof in the world. From 2016 it became the new home for

West Ham United Football Club, and the National Competition Centre for

athletics in the UK.

|

|

|

Roof erection

completed.

|

|

|

|

As viewed from the

adjacent ArcelorMittal Orbit structure in Queen Elizabeth

Olympic Park.

|

Project team

-

Principal contractor:

Balfour Beatty

-

Structural engineer:

Buro Happold

-

Erection engineer:

COWI

-

Steelwork

subcontractor: William Hare Limited

-

Cable-net

subcontractor: Pfeifer

-

Cladding

subcontractor: Lakesmere

-

Architect: Populus

"The use of LUSAS VB

Scripting techniques to customise the software and to automate the extensive

modelling and checking procedures required, allowed us to save a great

deal of time and ultimately confirm the

adequacy of the structural members which formed the permanent works

and global stability of the structure under the applied loads."

Dr Ahad Kolahi,

Project Manager, LUSAS

Share this

article

Find out more

Other LUSAS Civil &

Structural case studies:

|

|

Software Information

|