Case

Study Case

Study

Share this

article

Design of canopy

structures for Miami Central Station

-

Elliptical steel

arch canopy for Miami

Airport Metrorail Station

-

Moment resisting

steel frame for an access/entrance canopy

-

Aerofoil-like bus

station canopy

Miami

Airport Metrorail Station, designed by architects and planners Perez

& Perez, is the first main component being built for the Miami Central Station in Florida.

Genesis Structures used LUSAS finite element analysis to assist with

its design of a variety of canopy structures and roof panel components

for the project on behalf of its client, internationally acclaimed

engineering and fabrication company, Zarner.

Overview

Located next to the Miami International

Airport, the Miami Intermodal Center is a massive ground

transportation hub being developed by the Florida Department of

Transportation. The Miami Central Station forms a major part of this

development that, when complete, will connect the various

transportation systems of Palm Beach County, Fort Lauderdale, Miami,

and the Florida Keys.

Zahner was awarded

the construction contract for the engineered roof system for the main

canopy of the Metrorail Station, the South canopy and the bus station

canopy structures. Genesis Structures was selected by Zahner to

provide structural and erection engineering services for this work.

Metrorail Station

Canopy

The slotted canopy of the Metrorail

Station is the most prominent feature in the station complex. With a length of

nearly 500 feet, the structure consists of eleven structural steel

ribs, each of an elliptical profile, that are connected via baseplates

to an in-situ concrete framing support system. In designing the ribs

Genesis worked closely with the steelwork fabricator Columbia Wire

& Iron to develop details that accommodated their preferred

fabrication methods. Specially designed structural aluminum roofing

panels span between ribs to provide protection for the station

concourse.

|

|

|

|

Rendering of the

Metrorail Station structure |

Rendering of the inside of the

Metrorail Station |

Perez & Perezís design of the

canopy called for a planar roof structure that twists along the

horizontal axis of the canopy. This roof structure was designed with

Zahner as a structural aluminum box system approximately 60 inches in

depth, spanning approximately 43 feet, with full-depth slots to allow

natural light penetration into the station beneath.

|

|

|

Erection of

elliptical steel arches for main canopy |

|

|

|

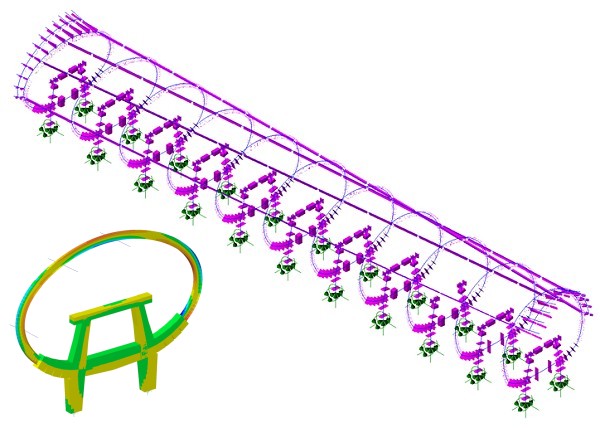

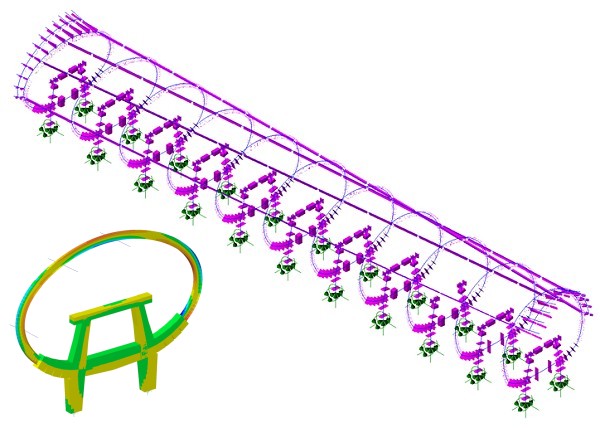

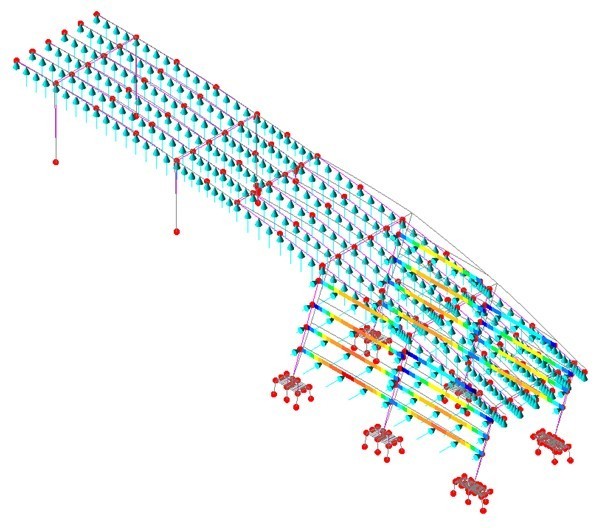

LUSAS modelling

of Metrorail Station structure |

South Canopy

The South Canopy contains elevators,

stairs and escalators which provide access from ground level to the

main canopy. It is designed as moment resisting steel frame supporting

the aluminum wall and roof panel system.

|

|

|

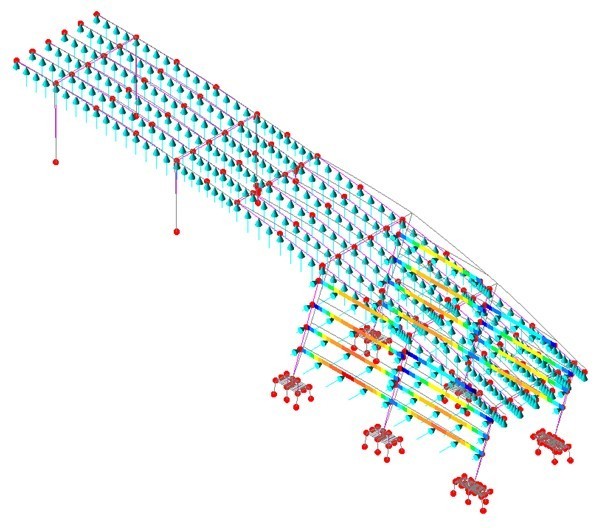

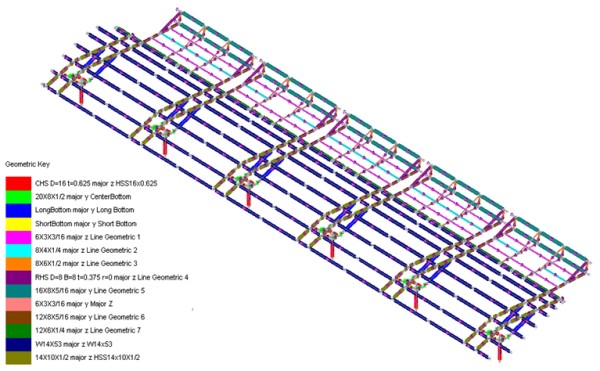

LUSAS model of

South Canopy |

Bus Station Canopy

The

aerofoil-like Bus Station Canopy structure provides access to

the main transportation hub for bus passengers. It consists of

a structural steel frame covered with full-depth aluminum roof

panels clad in a propriatory stainless steel finished skin.

Its design required careful coordination between Genesis

Structures and the engineer of record for the lower portion of

the Main Canopy due to the partial support conditions

provided. Special evaluation of wind loading on the large

horizontal surface was also undertaken and coordinated with

the wind consultant, RWDI.

|

|

Rendering

of Bus Station Canopy |

|

|

|

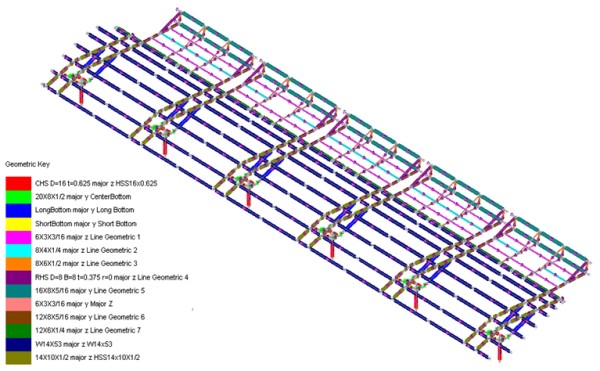

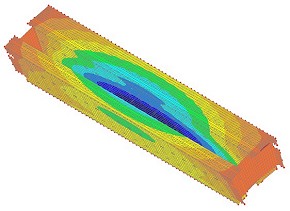

LUSAS model of

Bus Station Canopy |

Roof panels

Designing the various roof panels for

this project presented a particular challenge. Because of the stationís

location the structural components are subject to some of the most

severe wind loading in the United States. From scaled wind tunnel

analysis performed during the preliminary design phase of the project,

design wind pressures were arrived at for use on the structural and

cladding portions of the structures. The maximum design wind speeds of

150 mph that were used generated design cladding pressure loading of

nearly 130 pounds per square foot. LUSAS models of representative

panels were built and used to assess deflection and other criteria.

|

|

|

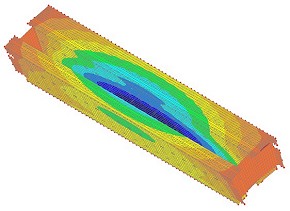

| LUSAS

model of typical roof panel |

First roof

panels in position on the main station canopy |

"We used LUSAS to model all

components of the Miami Airport Metrorail Station structures that we were

involved with. It allows easy importing of complex geometry models and

lets us apply all code-required load combinations in a very

straightforward way."

Dave Byers, Principal, Genesis Structures

Share this

article

Find out more

Other LUSAS Civil &

Structural case studies:

|

Case

Study

Case

Study