Case Study

Modelling the replacement of degraded concrete on the Terra Nitram

prill tower

-

Complex concrete refurbishment work

-

Global modelling of tower to assess areas of high stress

concentrations

-

Local modelling of staged construction analysis using 'Birth and

Death' elements

| The Severnside prill tower

was operated by Terra Nitrogen (UK) Ltd to manufacture ammonium nitrate fertiliser. Despite

a history of regular maintenance and repair, parts of the reinforced concrete structure

deteriorated over the years due to the severe operating environment,

and eventually significant structural repairs were required. ABB formulated an outline repair strategy

and design and technology consultants Taylor

Woodrow were appointed undertake the complete project management including the design

and supervision of the remedial works.

Taylor Woodrow chose to use LUSAS Civil &

Structural to assist with the complex task of modelling the demolition and

re-construction sequences to replace the degraded concrete in the tower whilst keeping the

plant operational throughout.

History

The tower was constructed in 1964. It consists of a 86m high, 15.6m

diameter drop shaft of 178mm thickness. A five storey reinforced concrete plant house,

supported on the drop shaft, a lift shaft and a single braced column, forms the upper 75m

to 100m levels. Despite protective measures being undertaken during its construction a

number of concrete repairs have had to be made during the tower’s life.

|

|

Global

modelling

Prior to the detailed staged construction design a LUSAS analysis of the complete

structure was undertaken for dead, plant, circulation and wind loads to assess the

structural behaviour of the tower both in its as-built and current deteriorated condition

for checking with relevant design codes. Fine mesh divisions were used in areas of repair

and coarse mesh divisions used in areas remote from the plant house.

Results from the as-built model confirmed the behaviour of the structure and identified

areas where high stresses could be expected. Results from the model incorporating reduced

modulii of elasticity for all areas of degradation showed how initial as-built forces had

redistributed due to the ammonium nitrate attack and indicated an even more urgent need

for the remedial work to be undertaken. This latter analysis also proved extremely useful

in deriving subsequent repair sequences. In all, over 100m2 of drop shaft wall and damaged

areas of beams, columns, slabs and walls for a number of levels of the plant house

required replacing.

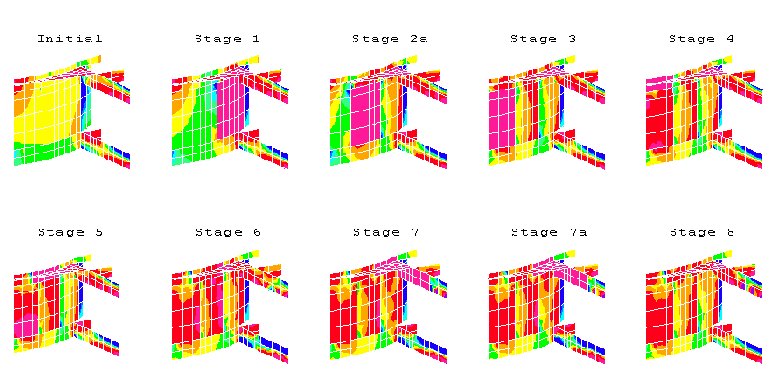

The LUSAS birth and death facility

The complex sequence of structural repairs was modelled in LUSAS using the birth and

death facility. This allows elements to be de-activated to simulate areas of concrete

removal, resulting in stress redistribution in the model. Following repair, the elements

are re-activated with corresponding new material properties. In this manner a structural

assessment was undertaken for all stages of the repairs to the tower including the use of

major temporary works such as support frames, props and jacks to ensure the structure

remained safe at all times.

Modelling of the staged repair sequences

While some local patch repairs were necessary at the lowest level of the plant house

the areas requiring most extensive repairs were between level 5 and the roof at 100m

level. Each level of the plant house presented different problems and required appropriate

repair sequences and temporary support arrangements. At each stage of the repair sequence

the forces in both temporary props and the support frame and the walls, columns, beams and

floor slabs of the plant house were examined in LUSAS to ensure the structure remained

safe. For the temporary support frame calculated deflections were compared with on-site

measurements to ensure nothing unexpected was happening. In general, good correlation was

achieved confirming the validity of the LUSAS modelling and design calculations.

Previous patch repairs to the drop shaft wall had

indicated that such repairs should be undertaken by a staged replacement of alternate

panels not exceeding of 1m x 2m in area. However, by using appropriate temporary works

including jacking, LUSAS confirmed that considerably larger areas could be broken out and

repaired in a single operation.

"Adopting the 'birth and death' technique

in the LUSAS analyses gave us a high degree of confidence that the structure would remain

safe at all times. This was of prime importance as the plant had to remain operational

thoroughout the duration of the repair contract."

Graham Anderson, Taylor Woodrow

Find out more

Other LUSAS Civil &

Structural case studies:

|