- Time history seismic analysis

using lumped-mass stick (beam) models

- Static and peak seismic loading

application using shell models

- Coupled thermal-structural

analysis for spillage plus aftershock event using solid models

Costa Norte LNG Terminal, Panama.

LUSAS

Consultancy Services has extensive experience in carrying out a wide range of

analyses for large storage LNG tanks. Over the years its specialist

engineers have assisted

Korea

Gas Technology Corporation

(KOGAS-Tech) on various projects and analyses including, more recently,

the seismic isolation analysis of a 180,000m3

full-containment tank for the Costa Norte LNG Terminal project in Panama. On completion in 2018, it

became the first LNG reception terminal in Central America.

Overview

Panama and Central America are seismically active regions and LNG

tanks represent critical structures with stringent design

requirements under accidental and earthquake conditions. In this

context, base-isolation systems have become a cost-effective

solution to cater for increasing seismic demands in the design of

large storage tanks.

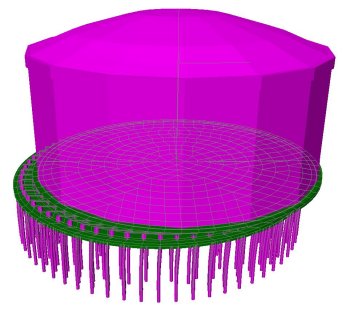

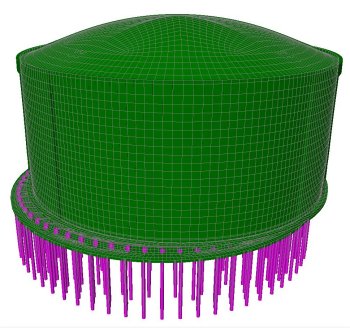

This

above-ground full containment tank comprises a 32.7m high, 9% nickel steel inner tank of

89m diameter - where the LNG is stored under

normal operating conditions - insulated from a 91m inside diameter post-tensioned

concrete outer tank intended to

contain any accidental spillage of LNG product. The base insulation sits on a concrete base slab

supported by 400 pedestal-mounted isolators, which are cast on top

of a reinforced concrete piled raft foundation. The overall tank

height to the top of the roof dome is 53.4m.

Analyses undertaken

LUSAS Consultancy

developed several finite element models to perform a detailed seismic assessment

of the LNG tank under different earthquake and accidental

conditions, including:

- Time history seismic analysis

using lumped-mass stick (beam) models

- Static and peak seismic loading

application using shell models

- Coupled thermal-structural

analysis for spillage plus aftershock event using solid models

|

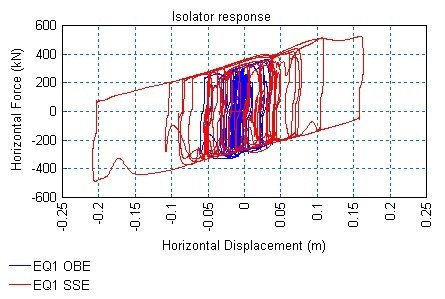

Isolation system

Triple friction

pendulum bearing (TFPB) isolators were located under the tank

bottom slab in order to decouple the tank from the earthquake

ground motion and reduce the transmission of seismic energy to

the tank components.

In all, 400

pedestal-mounted TFPB were used, with 4 sliding concave

surfaces and 3 friction coefficients. These were modelled in

LUSAS using specialised joint materials which included

hysteretic damping and the variation of friction with sliding

velocity and normal pressure. As friction properties are

variable with time and also axial force, lower and upper bound

properties were used for the empty and full tank cases.

Under peak conditions, the

base-isolation was able to provide an overall effective damping of

up to 33%, with peak displacements of around 200mm, well within the

605mm bearing capacity.

|

Installation

of base isolation system

(Image: AES Colon)

|

|

|

|

|

|

| Isolator

force-displacement curve |

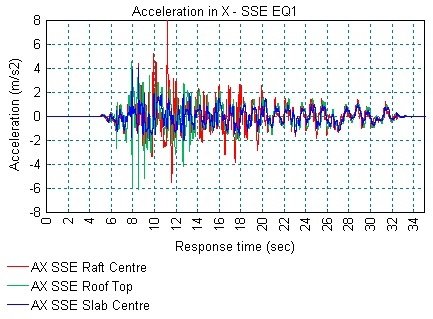

Acceleration-time

reponse in horizontal direction |

|

|

|

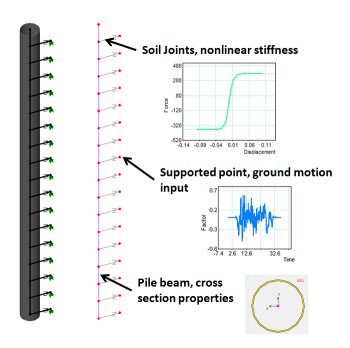

Soil-structure

interaction

The tank

foundation included a large number of closely spaced steel

piles, fully embedded in rock.

Piecewise linear joints

materials varying with depth were used in LUSAS to simulate

the nonlinear response of soil, including lateral bearing

capacity, skin friction and end bearing resistance.

Liquefaction

potential, cyclic loading, group effects and soil damping were

considered in the computation of the axial and lateral

stiffness of the soil support.

|

|

|

Pile modelling |

Time-history seismic

analyses

Lumped mass modelling

was used for fluid/structure interaction of the LNG and for

soil/structure interaction of the pile arrangement. The

nonlinear hysteretic behaviour of the isolation system required a

detailed dynamic analysis. Using nonlinear transient dynamic

analyses in LUSAS, time-history responses were obtained under

simultaneous horizontal and vertical ground motion.

Bedrock input motions of

0.33g (Operational Basis Earthquake) and 0.54g (Safe Shutdown

Earthquake) from the seismic hazard analysis provided by KOGAS-Tech were

used to develop multiple ground motion records to satisfy code

requirements.

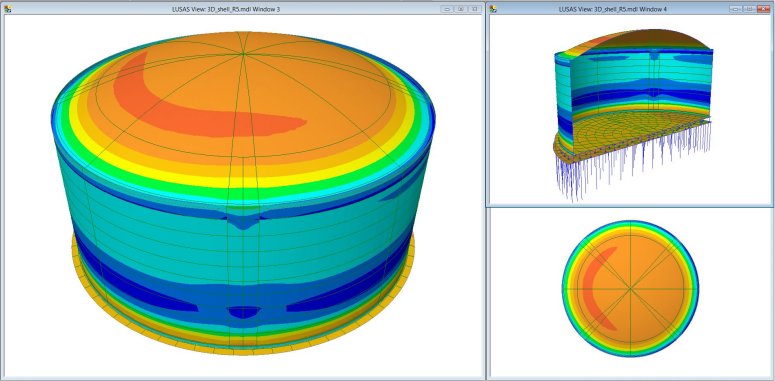

The peak averaged results from the

dynamic analyses were combined with normal operation static loading

to perform a detailed stress analysis on a 3D shell model of the

structure.

|

|

|

| Lumped mass model

deformation |

Shell model

deformation |

|

|

|

|

| Hoop

axial forces in shell model |

Spillage and

aftershock

A critical design

condition of LNG tanks is the aftershock (SSEaft)

event following an accidental spillage, which is assumed as a

result of a prior SSE earthquake that has damaged the inner

tank.

The aftershock earthquake was

estimated as 50% of the SSE, and the time-history analysis was

repeated on the lumped mass model considering that in this

case the LNG is in direct contact with the outer tank.

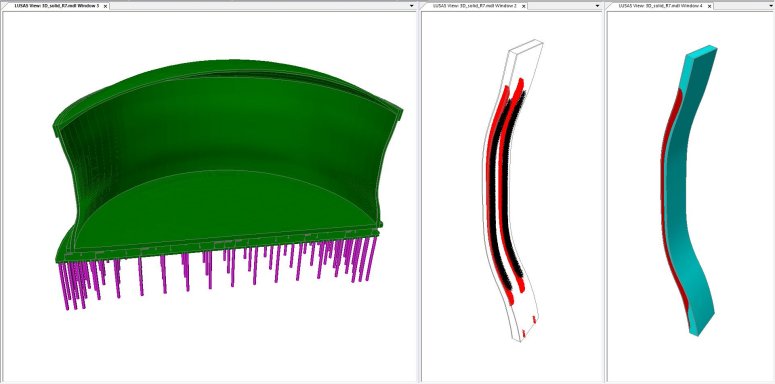

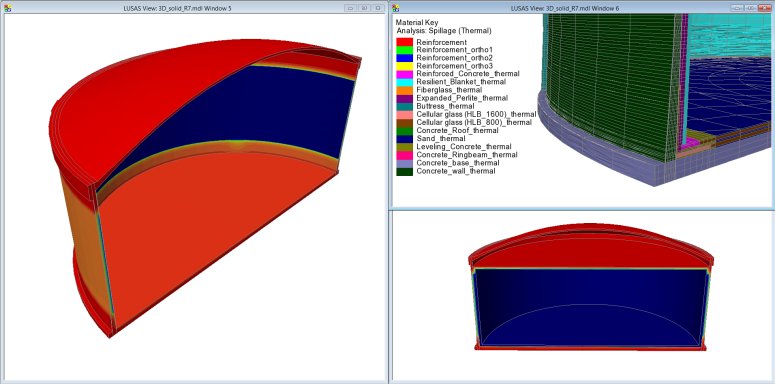

A 3D solid model

that included a state-of-the-art

nonlinear concrete material was developed to carry out a

semi-coupled steady state thermal analysis to assess the

effects of the spillage on the tank wall. Similarly, as for

the shell model, peak hydrodynamic pressures were subsequently

applied to the solid model and the liquid tightness and

collapse prevention of the concrete tank were assessed.

|

|

| Solid model

deformation | Cracking / crushing | Compression zone

|

|

|

|

|

| Spillage

temperature results and tank material modelling

|

In summary

Using the most advanced

finite element analysis/modelling techniques for isolated LNG tanks, LUSAS

Consultancy Services was able to provide KOGAS-Tech with a design basis

for the tank checks under OBE, SSE and SSEaft conditions;

including relevant results for foundation forces, isolator response,

freeboard, concrete tank forces, liquid tightness, crack widths, and

more.

"LUSAS has

provided us with a powerful design capability and advanced technical

support for over 20 years. On the Costa Norte LNG Terminal

project, the

use of LUSAS successfully verified our tank design for a highly

seismic region. With LUSAS, we can always ensure that our LNG tank

designs meet the strict design requirements of our clients."

Jung-Hoe

Kim, Civil & Arch Dept Manager, KOGAS-Tech.

Share this

article

Find out more

Other LUSAS Civil &

Structural case studies: