Case Study Case Study

Share this

article

Rail track / structure interaction

analysis for the Dubai Metro light rail project

-

2D modelling of

rail / structure interaction modelling to UIC 773-4

-

Verification

of spreadsheet calculations

-

Potentially

problematic results proved by LUSAS to be within project design

criteria

The Red and Green

Lines of the Dubai Metro light rail scheme are being constructed

as a Design-Build contract by a consortium of international

contractors. Atkins,

one of the world’s leading engineering and design

consultancies, is the lead designer to the major civil

contractor of the Dubai Rapid Link (DURL) Consortium and is

carrying out the full multi-disciplinary design and project

management of the civil works for the project. Atkins used LUSAS

Bridge analysis software to verify its rail track interaction

spreadsheet calculations to the International Union of Railways

Code UIC 774-3, and to obtain more accurate and ultimately

design-complying results for situations that the spreadsheet

calculations had identified as exceeding project design values.

|

Overview

The

52km long Red and 24km long Green Lines of the Dubai Metro run mostly

on elevated single span pre-cast post-tensioned concrete deck units of

U-shaped cross-section. Deck crossbeams sit on elastomeric bearings,

with fixed and free guided sliding pot bearings being used for two and

three-span continuous decks. Standard spans are typically 28m, 32m or

36m in length, with each end supported on a flared pierhead sitting on

a single, circular, reinforced concrete column. Rails are continually

welded across all the decks and deck joints, and connected to concrete

plinths running the length of each deck using regular track fixings.

A detailed assessment of the

interaction of the track with respect to the deck structures was

needed in order to derive stresses in the rails and forces and

longitudinal displacements induced in the deck caused by both thermal

and train loading.

|

|

Spreadsheet calculations

Based upon the formulae and design

methods specified in the UIC 774-3 code Atkins set-up spreadsheets to

calculate rail track/structure interaction effects for around 1200

spans on both the Red and Green Lines. Whilst based on the simplified

techniques of the UIC code and producing generally conservative

results this spreadsheet approach had the benefit of allowing a large

number of span arrangements to be assessed relatively quickly.

|

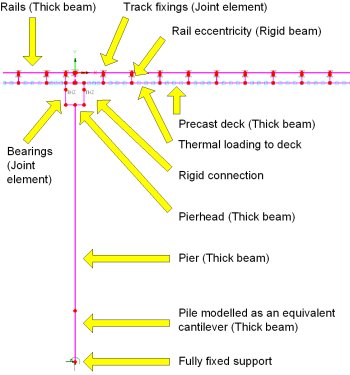

Modelling with LUSAS

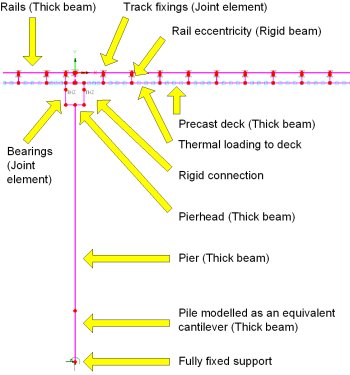

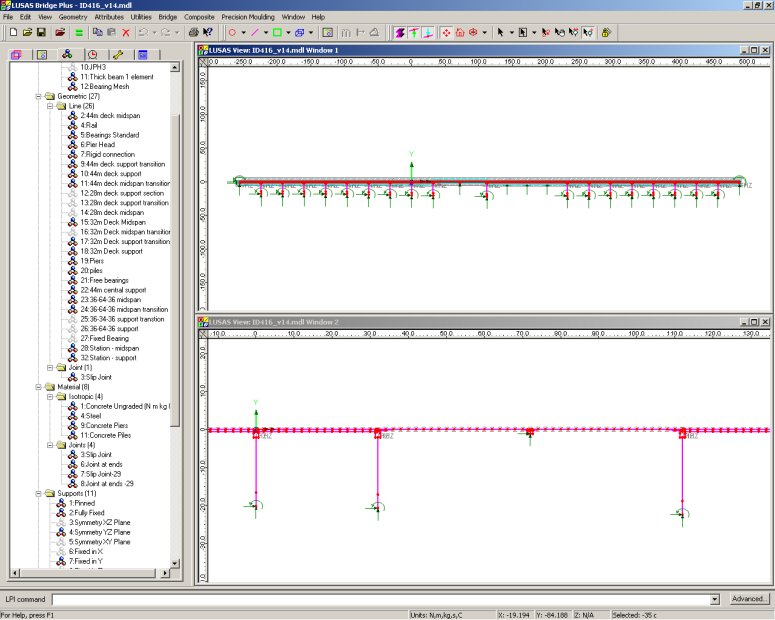

To

verify the results obtained from the spreadsheets Atkins used LUSAS to

model and analyse a number of representative span arrangements. Models

were built using thick beam elements to represent the piles, piers,

crossbeams and concrete decks. Pile modelling was done using the

equivalent cantilever method (as opposed to modelling the

soil/structure interaction as a beam with elastic springs). Joint

elements of an appropriate stiffness and at the required locations

modelled the elastomeric and other bearing types. A single thick beam

element offset by an appropriate eccentricity from the deck

represented both sets of rails. Nonlinear joint elements modelled the

track fixings. Thermal loadcases were applied to the elements

representing the deck according to the UIC 774-3 code. Train loading

of both vertical live loading and horizontal braking loads were

applied to the elements representing the rails at locations of

interest in the model.

|

|

|

|

|

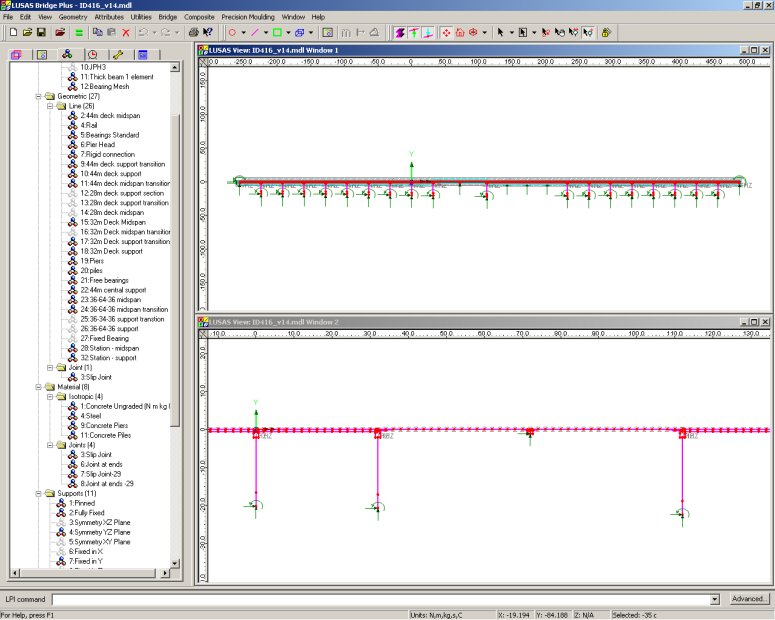

LUSAS modelling of

a multi-span arrangement including a 2-span and 3-span

continuous deck |

Rachel Jones, engineer on the project

said: "For the LUSAS verification modelling we chose a selection

of span arrangements that would give us a variety of effects for a

combination of single, 2-span and 3-span continuous decks. The

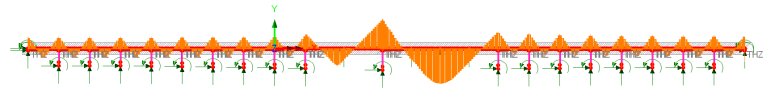

stresses in the rails obtained from the LUSAS analyses proved our

spreadsheet calculations were being carried our correctly".

However, for a small number of span arrangements the rail structure

interaction forces obtained from the spreadsheet calculations were

shown to exceed project design values. Each of these situations required

additional LUSAS models to be created for a detailed analysis to be

carried out. The primary difference between analysis to the UIC-773

code and using LUSAS is that modelling in LUSAS is more realistic

(using nonlinear joints to model the track fixings for example) and

makes no assumptions on the behaviour of the structure. Results

obtained from the LUSAS analyses showed that the rail/structure

interaction values of initial concern did not actually exceed the

project design values.

|

|

|

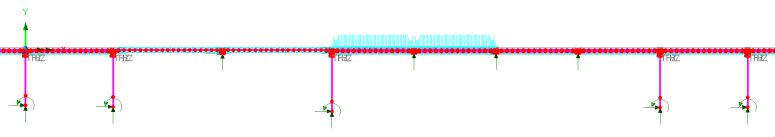

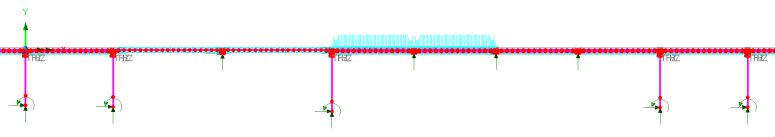

Loading

configuration: temperature loading to deck and vertical live

train loading with braking forces (not visible) in first two

spans of station |

|

|

|

|

|

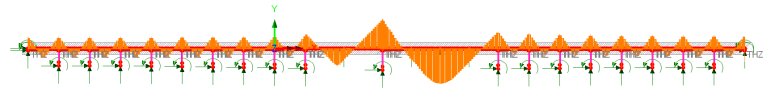

Stress in rails

from applied thermal and train braking loading |

"By using LUSAS to investigate

these span arrangements we got a more accurate assessment of the rail

track interaction effects and obtained values that did not exceed

design criteria"

Rachel Jones, Atkins

| Automated

rail track / structure analysis with LUSAS

If it had been available at the

time Atkins carried out its own manual

2D modelling and analysis of rail track / structure interaction

effects as described in this case study, the LUSAS

Rail Track Analysis software option for LUSAS

Bridge would have let Atkins carry out automated 2D modelling of track/structure

interaction analysis to the International Union of Railways Code

UIC 774-3.

With this option, track and bridge

interaction models are built automatically in LUSAS from

geometric, material property, and loading data defined in a MS

Excel spreadsheet. Both thermal loading to the track and train

loading due to acceleration and braking forces can defined. Rail

clips, ballast movement, bearings and pier stiffnesses are all

included in the analysis model. The model building dialogs allow

for either one train crossing one or more structures, or for

multiple trains crossing the same structure.

When running an analysis, deck

temperature loading can be considered in isolation for

subsequent analysis of multiple rail configurations, or a full

analysis can be carried out considering the combined temperature

in the deck and rail loading. Because the response of the

ballast and/or track fixing clips is nonlinear, a nonlinear analysis always

needs to be carried out. After running an analysis, results can

be quickly obtained in both spreadsheet or LUSAS results file

formats.

A key benefit of using the LUSAS

Rail Track Analysis software option is that it automatically

updates the material properties associated with the

track/structure interface based upon the position of the train

or trains crossing the bridge - something not easily done by

manual or other software methods. |

Other analyses undertaken by Atkins on

the Dubai Metro light rail project using LUSAS include:

Share this

article

Find out more

Other LUSAS Bridge case studies:

|

|

Software Information

|