Software Tour

Analysis and design capabilities

Analysis and design capability is dependent upon the

product in use. Particular LUSAS Bridge software products can be

extended by using software options. For details see the

Software Specifications.

The main analysis capabilities

are summarised here.

Multiple analysis

and branched analysis

When designing your

structure, more than one type of analysis can be defined and solved independently

from within one model using the multiple analysis and branched

analysis facilities. This means that, in most cases, there is no

need to create separate models and maintain clone copies of a model,

in order to analyse and view results for different analysis

requirements.

Analysis

branches allow the creation and solution of one or more sub-analyses

to investigate the response of the model at a particular loadcase or

"stage". Use analysis branches to:

- Carry

out a linear moving load analysis of construction equipment during

each stage of the construction of a segmental bridge deck.

- Perform

an eigenvalue natural frequency analysis or a buckling analysis

during construction.

- Perform

a phi-c reduction analysis to derive safety factors for a

geotechnical model from each stage in an excavation process.

- Perform

an earthquake analysis where gravity is applied in a static

nonlinear step, then the earthquake is run as a transient branch.

Several sample earthquakes may be run in each branch.

Linear static

- Stresses, strains, displacements, moments, shears and axial

forces that result from static loading are easily calculated,

displayed and output from any model.

|

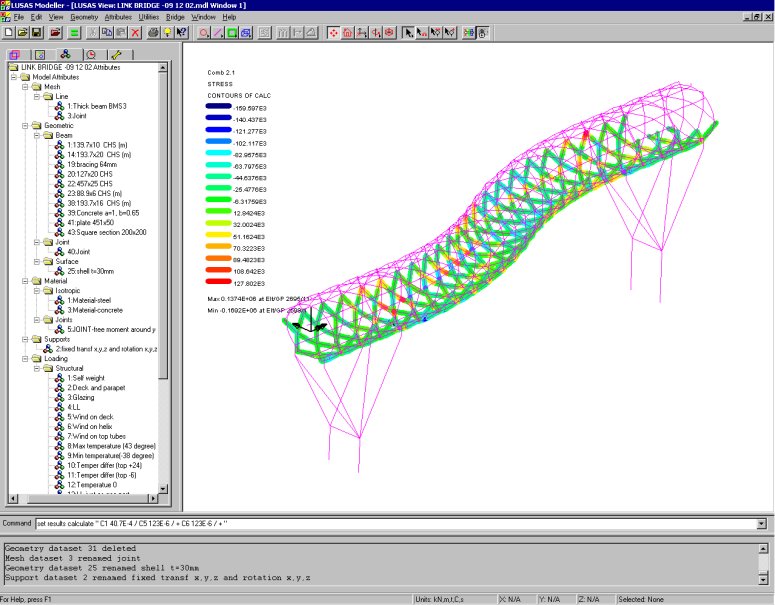

Cable tuning analysis

Perform

linear and nonlinear cable tuning analysis. Use

nonlinear

cable tuning when geometric, material or

boundary nonlinearity may exist, and for use in obtaining pre-stressed

states of existing structures, or for modelling catenary effects.

Both cable tuning

analysis facilities calculate load factors for cables in order to

achieve defined target values set for various feature types or results

components. An 'exact' method, an optimisation facility and two

best-fit solution methods are provided.

|

|

Target values analysis

Use the target values post-processing

facility to vary load

factors in a linear analysis to try and achieve target values

specified for particular feature types or results components. The target values

loadset created is similar to a combination, but the load factors are

automatically calculated by the program in response to the defined

targets.

|

Buckling

Carry out elastic critical buckling, which is required for the calculation of

member resistances. Often it is also required by some codes to

determine if a second-order analysis needs to be carried out. If so, a

full nonlinear buckling analysis can be undertaken.

-

For existing

structures, assessment or load rating to regional design codes can

give conservative results showing they ‘fail’ buckling checks,

but detailed buckling analysis with LUSAS can often reveal

additional ‘hidden’ capacity and prove a load capacity.

-

For new plate

girder, box or tub girder bridge designs, linear and nonlinear

buckling analysis using LUSAS can investigate the girder stability

during erection, look at the effects of a slab casting sequence,

and also help to optimise the size of the web and flange plates,

bracing, stiffeners and position of any temporary supports used.

-

See Linear

and Nonlinear Buckling Analysis for more information.

|

|

|

Fatigue

Carry out fatigue

calculations using the total life approach. Express fatigue life in terms of the damage that is done to

the structure by a prescribed loading sequence or as the number of

repeats of a sequence that will cause failure.

|

|

Direct Method influence

analysis

Direct Method influence analysis is a

general and powerful way of calculating influences for line beam,

frame, grillage, slab and deck models. The effect of a specified point

load is assessed at each node or grid location on a loadable area of a

structure. Calculate the influences for any results entity /

component according to the elements used, as well as for user-defined

results components, for many locations and

quantities within a single analysis.

|

|

|

|

Direct Method Influence

definition

|

Direct Method Influence

assignment

|

|

Dynamics

LUSAS Bridge excels in solving seismic and

general dynamics problems. Straightforward

modal dynamics problems can be solved using Interactive Modal Dynamics

(IMD) techniques which are provided in selected LUSAS Bridge products.

The Dynamics software option

contains the facilities required to solve a wider range of dynamic

problems in the time domain with a step-by-step solution.

Additionally, by combining the LUSAS Dynamic and LUSAS Nonlinear

options both high and low velocity nonlinear impact problems can be

solved using either implicit or explicit solution techniques.

The natural frequency

of structures, the effect of dynamic loading, such as pedestrian

loading on footbridges and responses due to earthquake or impact

loading can all be readily calculated.

|

|

|

|

|

|

Capabilities include:

|

|

|

|

-

Blast

loading

-

Ship impact

-

Seismicity

|

Forced response, vibration and transient dynamics problems can also

be solved, if you wish, by calculating the structural response for selected loadcases

using the Interactive Modal Dynamics (IMD) results processing facilities.

Interactive

Modal Dynamics (Modal superposition)

Interactive

Modal Dynamics (IMD) allows the natural vibration behaviour of a

structure to be combined with a loading regime in order to calculate

the dynamic response of a structure to a range of applied excitations.

IMD produces results an order of magnitude faster than traditional

time-step solutions. Multiple and more advanced loading events

(including moving loads and nonlinear behaviour) can be modelled with

the IMDPlus and additional software options.

|

The

IMDPlus software option extends the

Interactive Modal Dynamics (IMD) techniques available in all LUSAS

products, and which model a single loading event in a single

direction, to allow multiple loading events with more advanced loading

conditions to be solved.

The

IMDPlus option is used for two primary uses: seismic response analysis

of 2D and 3D structures subjected to acceleration time histories of

support motion, and for the analysis of 3D structures, such as

bridges, subjected to constant moving vehicle or train loads, and

moving mass and moving sprung mass.

|

|

Staged

construction analysis

See LUSAS Bridge Staged Construction Modelling

Prestress

analysis

See LUSAS Bridge

Load types and combinations

Vehicle

load optimisation

See LUSAS Bridge

Load types and combinations

Nonlinear

An

analysis will often have to take account of nonlinear materials,

geometry, and support boundary conditions to accurately model the

structural behaviour. The LUSAS Nonlinear

software option provides the very latest powerful techniques for

solving problems having:

- Geometric

nonlinearity (large deformations, finite rotations and large

strains)

- Material

nonlinearity (concrete, steel, rubber and geotechnical material

models)

- Contact nonlinearity

(point and surface).

Local and

global nonlinear analysis with LUSAS helps ensure that bridges are

designed economically and safely for any imposed loading. Automatic

nonlinear solution procedures simplify the analysis process for

applications such as:

-

Modelling

lift-off

of bearings and halving joints

-

Lead-rubber

bearing analysis, bearing collapse

-

Elasto-plastic

large deflection plate buckling

-

Large

deflection cable analysis

-

Soil-structure

interaction / integral bridge design

-

Masonry

arch analysis

-

Time-dependent

dynamic analysis

-

Vehicle

and boat impact assessments

-

‘Push-over’

analysis

-

Large

deflection in cable structures

The Nonlinear option

can also be combined with the LUSAS Dynamic and Thermal / Field software

options to solve problems in which the effects of time and temperature

are important.

P-Delta

analysis

P-Delta analysis

is available for bar, beam, thick and thin shell, and 2D and 3D

continuum elements with GNL capability. P-Delta analysis is an

approximate geometrically nonlinear (GNL) analysis typically used to

take account of the interaction between vertical and horizontal (sway)

loading on tall, slender buildings. Vertical constant loads (usually

dead loads) are used to form the geometric stiffness (stress

stiffened) matrix for the structure; additional live load cases can

then be applied and load combinations used to capture the effects of

the interaction between lateral and vertical loading.

Creep

modelling

-

Concrete creep

including fib (formerly CEB-FIP) and Chinese model codes

-

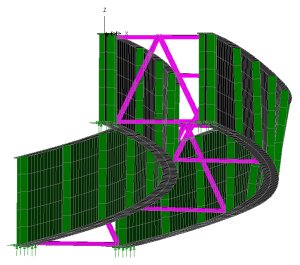

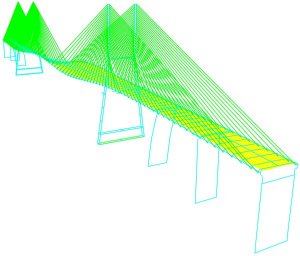

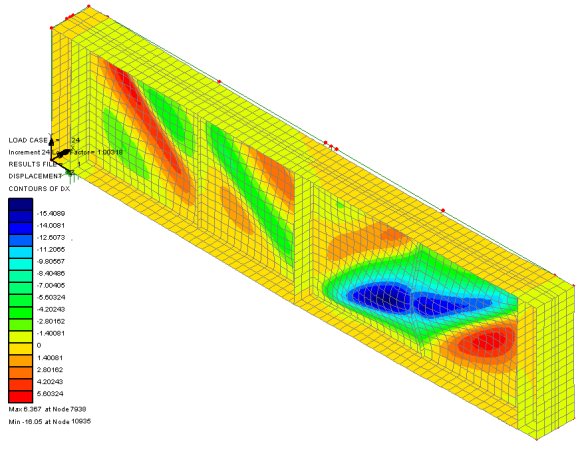

The image

(right) shows just a few exaggerated deformed shapes of a beam and

shell model used to carry out a staged construction analysis

(incorporating creep and post tensioning) to simulate the

construction of the deck of a proposed bridge across the

Mississippi River.

|

|

|

Soil-structure

interaction

-

Useful

geotechnical capabilities make use of a range of soil

models.

-

Residual

soil stress varying with depth can be accommodated providing

useful facilities for soil-structure interaction for integral

bridges and culverts.

-

Rock

joints, pore water pressure dissipation, consolidation modelling,

geotechnical problems involving long term excavation, construction

in clays, and temporary works can all be solved.

See Geotechnical

/ Soil-structure modelling

for more information.

|

|

Thermal

/ field analysis

The Thermal

/ Field software option contains extensive facilities for both

simple and advanced steady state, and transient thermal / field

analyses. By combining the LUSAS Thermal / Field option with other

appropriate LUSAS options, heat transfer due to conduction, convection

and radiation can be analysed. In addition, the effects due to phase

change of material may also be included.

|

Heat of

Hydration

Modelling

of heat of concrete hydration can be carried out for a variety of

cement types using the using the Heat

of Hydration software option. Effects due to the addition of fly

ash and ground granulated blast furnace slag can also be included.

When used in conjunction with Nonlinear, Dynamic, and Thermal software

options the heat of concrete hydration can be computed during a

thermo-mechanical coupled analysis and the temperatures and degree of

hydration can be read in to the mechanical analysis.

|

|

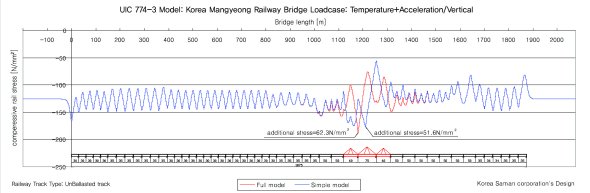

Rail Track

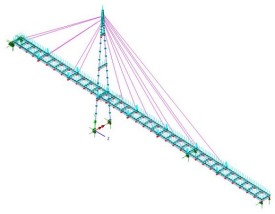

Analysis

When used

with the Nonlinear software option the LUSAS Rail

Track Analysis software option automates track/bridge interaction

analysis for light and high speed rail projects to the International

Union of Railways Code UIC 774-3. It allows you to automatically build

models from data defined in Excel spreadsheets, run an analysis, and

quickly calculate stresses and forces induced in the track from both

thermal and train loading. Parametric positioning of train loading is

supported, results graphs are automatically created and exported to

Excel spreadsheets, and code checking results tables are generated.

Faster

solution times

The Fast

Solver option comprises additional solvers for use with particular

LUSAS Bridge products.

-

The

Fast Multifrontal Direct Solver can provide solutions several

times faster than the standard Frontal Direct Solver for certain

analysis problems.

-

The

Fast Multifrontal Block Lanczos Eigensolver can, similarly, return

results.

several times faster than the standard Frontal Eigensolvers for

certain problems.

-

The

complex eigensolver provides efficient solutions for large-scale

damped natural frequency problems.

-

The

Fast Parallel Direct Solver and Fast Parallel Iterative Solver

will solve large sparse symmetric and non-symmetric equations on

shared memory multiprocessors.

Design

code facilities

Find out more

|

|

Software Information

|