Additional Information

See the adjacent Software Information

links for general details regarding LUSAS Bridge software products and

options.

Integral or Jointless Bridges

Integral or jointless bridges are well known to

eliminate the maintenance and salt corrosion problems associated

with bridges having movement joints and bearings. However, the

biggest uncertainty with the design of these types of structures

is the reaction of the soil behind the abutments and adjacent to

the foundation piles caused by seasonal thermal expansion of the

various bridge components acting together. LUSAS Bridge,

unlike some systems, allows you to accurately analyse the

soil-structure interaction of the piles and bridge structure in

one model and comprehensive results processing features give you with

all the tools you need to view and interpret your results.

Overview

Integral bridges,

or jointless bridges (as they are more commonly known in

the USA) are constructed without any movement joints between

spans or between spans and abutments. Typically these bridges

have stub-type abutments supported on piles and a continuous

bridge deck from one embankment to the other. Foundations are

usually designed to be small and flexible to facilitate

horizontal movement or rocking of the support. Integral bridges,

or jointless bridges (as they are more commonly known in

the USA) are constructed without any movement joints between

spans or between spans and abutments. Typically these bridges

have stub-type abutments supported on piles and a continuous

bridge deck from one embankment to the other. Foundations are

usually designed to be small and flexible to facilitate

horizontal movement or rocking of the support.

With integral

bridges thermal deck movements are accommodated by soil

structure interaction between the supporting piles and the

surrounding strata. Deck loading is also affected by the soil

which acts as both load and support system to the piles upon

which the structures are founded. Specifying a series of spring

supports along a pile to approximate soil behaviour is a

commonly used modelling method when the structural load effects

are the main item of interest. When the soil movement is of

interest continuum models are used instead.

Integral bridges

present a challenge for load distribution calculations because

the bridge deck, piers, abutments, embankments and soil must all

be considered as a single compliant system.

Integral

Bridge Types

There are two main types of

integral abutment bridge:

- Those with short stub-type

abutments that sit on piles and support the deck beams or

slab.

- Those with full abutment

walls, sitting on piles, that retain the ground behind the

wall as well as support the deck beams or bridge slab.

Whilst some analysis systems require

you to use a pile design package to analyse the soil-structure

interaction of the piles before passing results to and from the

structural analysis design package, LUSAS Bridge handles it all

within one analysis system - greatly simplifying your modelling and

analysis.

Modelling and analysis with LUSAS Bridge

With LUSAS Bridge you can model

and analyse

integral abutment bridges in a number of ways:

- 2D beam model with Winkler springs to

represent the horizontal soil continuum.

- 2D continuum model (plane strain) with

staged construction and nonlinear materials for drained and

undrained soil conditions.

- 3D beam analysis with Winkler springs

to represent the horizontal soil continuum.

- 3D shell and beam analysis with

Winkler springs representing the horizontal soil continuum.

- 3D shell analysis with 3D (volume)

continuum to represent the soil.

- Full 3D analysis.

|

|

|

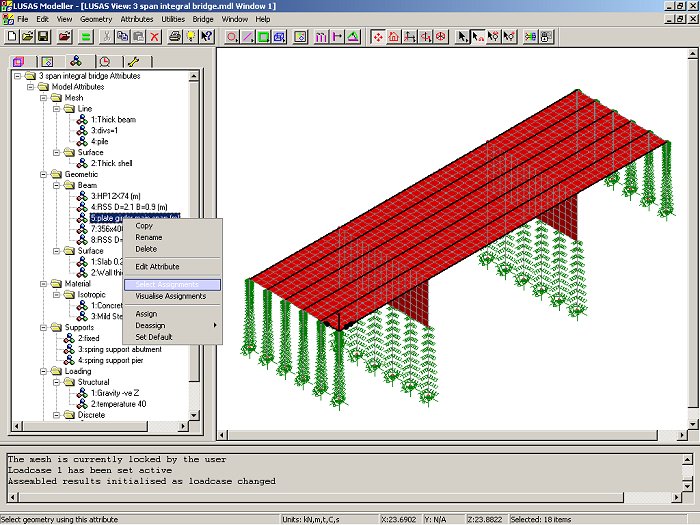

Integral

abutment bridge model using 3D shells and beams with spring

supports representing the horizontal soil continuum. |

Viewing of

results

The following

results are from an analysis of a 3-span integral composite

bridge comprising a concrete deck on steel girders with

concrete diaphragms and abutments supported on H-piles.

Additional

information

In the UK, the Highways Agency Departmental

Standard, BD57, "Design for Durability", requires

designers to consider designing all bridges with lengths of up

to 60 metres and skew angles of less than 30 degrees as integral

bridges. This advice is intended to prevent problems of joint

leakage over supports and reinforcement corrosion that typically

occur in non-integral forms of bridge construction.

In the UK, the Highways Agency Departmental

Standard, BD57, "Design for Durability", requires

designers to consider designing all bridges with lengths of up

to 60 metres and skew angles of less than 30 degrees as integral

bridges. This advice is intended to prevent problems of joint

leakage over supports and reinforcement corrosion that typically

occur in non-integral forms of bridge construction.

In the USA, integral abutment bridges have been built since the

1960s and are increasingly being used for replacement

structures. Lengths of integral abutment bridges are also

increasing and now the state of Tennessee builds steel

superstructure bridges up to 400 ft. (122m) long with no joints;

and concrete superstructure bridges of this type up to 800 ft.

(244m) and sometimes longer. One case in point is the bridge

carrying Route 50 over Happy Hollow Creek - at a total length of

1,175 ft. (358 m), it is the longest, jointless, integral

abutment bridge in the country.

In the USA, integral abutment bridges have been built since the

1960s and are increasingly being used for replacement

structures. Lengths of integral abutment bridges are also

increasing and now the state of Tennessee builds steel

superstructure bridges up to 400 ft. (122m) long with no joints;

and concrete superstructure bridges of this type up to 800 ft.

(244m) and sometimes longer. One case in point is the bridge

carrying Route 50 over Happy Hollow Creek - at a total length of

1,175 ft. (358 m), it is the longest, jointless, integral

abutment bridge in the country.

Paper

and Presentation: Integral Bridges and the Modeling of Soil-Structure

Interaction

-

Paper presented at IBC

2014 by Steve Rhodes and Terry Cakebread of LUSAS.

-

At the time of writing

the paper, no standard approach for the analysis of integral

bridges appears in AASHTO LRFD Bridge Design Specifications or

other international codes. This paper considers the approaches

most suitable for modeling common integral bridge forms, expanding

upon recent guidance regarding soil-structure interaction

approaches. Issues including material properties, initial stress

state and the incorporation of the effects of soil ratcheting are

discussed and both continuum and spring-type finite element models

are explored.

-

View

paper | View

presentation

Share this

article

|