Case Study Case Study

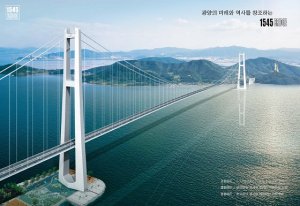

Deck segment analysis for Yi Sun-sin Bridge

-

4th longest

suspension bridge in the world

-

Linear

static analysis of twin box steel deck segments

-

Diaphragm

design strengthened and optimised

Yooshin

Engineering Corporation

used LUSAS Bridge analysis software to carry out a detailed analysis of a

6 metre long twin-box steel girder deck segment for use on the Yi

Sun-sin Bridge in Yeosu City,

Cheonnam, South Korea on behalf of its client the Cheonnam Provincial

Government. The bridge links Gwangyang to Yeosu city. The bridge is named in

honour of a famous Korean sea hero, Admiral Yi Sun-sin, an enormous

statue of whom will overlook the bridge. He was born in 1545 and

which, by deliberate design, is also the length of the main span of

the bridge in metres

Overview

The

bridge is a three-span suspension bridge of 357.5 + 1545 +

357.5 metre spans which, at a total of 2260 metres in length, and when

completed will be the fourth longest in the world. Concrete towers are H-shaped and at a

height of 270 metres are the highest in the world. The height from sea

level to the underside of the deck is in the order of 85 metres to

allow for the largest container ships in the world to pass safely

beneath the bridge. Preliminary design commenced in 2006 with detailed

design work taking place throughout 2007. Understanding how the twin

box girder deck section would behave under all loading conditions was

difficult to ascertain so LUSAS Bridge analysis software was chosen to

carry out a detailed analysis. The

bridge is a three-span suspension bridge of 357.5 + 1545 +

357.5 metre spans which, at a total of 2260 metres in length, and when

completed will be the fourth longest in the world. Concrete towers are H-shaped and at a

height of 270 metres are the highest in the world. The height from sea

level to the underside of the deck is in the order of 85 metres to

allow for the largest container ships in the world to pass safely

beneath the bridge. Preliminary design commenced in 2006 with detailed

design work taking place throughout 2007. Understanding how the twin

box girder deck section would behave under all loading conditions was

difficult to ascertain so LUSAS Bridge analysis software was chosen to

carry out a detailed analysis.

Modelling and Analysis

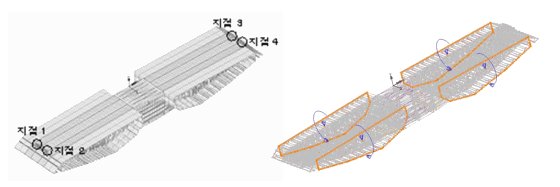

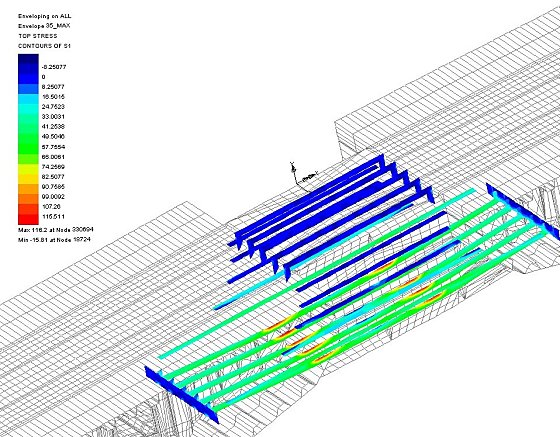

Using LUSAS, all webs, flanges, ribs

and other small members in the 6 metre long deck segment were

modelled. Vertical supports were placed at the hanger positions, and

moment supports were placed along edges where deck sections would join

to ensure the localised model would correctly match the global

behaviour of the bridge.

Four-lane Korean DB24

truck loading was applied as well as lane and distributed loadings,

and a linear static analysis was carried out. In all, 6 load

combinations consisting of 24 different vehicle loadings and dead

loads were analysed and investigated using the range of results

processing facilities available.

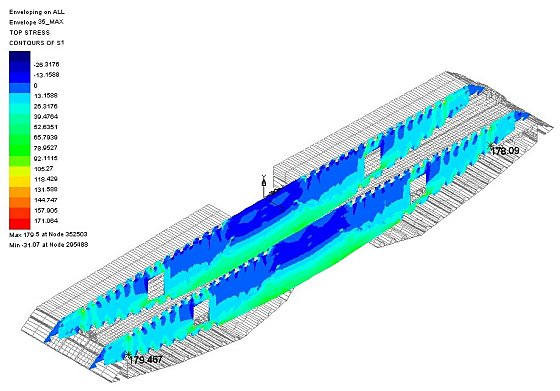

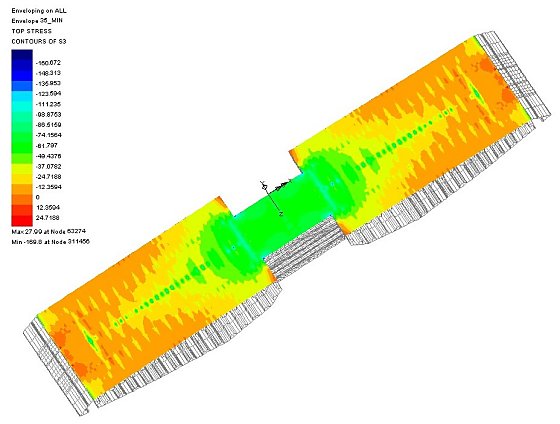

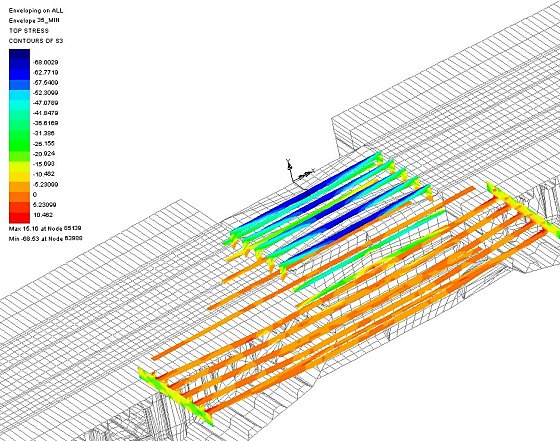

Slice sections through the diaphragm

were taken in areas of interest and both principal stress and

von-Mises stress were compared with the allowable stress for the SM490

steel members of the diaphragm and transverse box. From the detailed

LUSAS analysis it was seen that the main structural behaviour was in

the transverse direction, and, as result, it was seen that the initial

diaphragm design needed to be strengthened. Typical results plots

follow:

Construction of the bridge started at

the end of 2007 and completion is scheduled for early 2012. Total

project cost is in the region of 434 billion Won.

|