Inspection and Assessment Whilst the bridge had been regularly maintained since its construction extreme weather and environmental conditions slowly took their toll. In 2000 an inspection by CIL engineers revealed areas of spalled concrete and reinforcement corrosion. In 2002, CIL appointed RPS (then M.C. O’Sullivan and Company Ltd.) to conduct a further inspection and in-depth structural assessment of the footbridge. RPS undertook material tests, observations and geometrical surveys to help establish the condition of the structure and to provide material and geometric parameters for use with maintenance, repair or strengthening scheme development. Defects noted during the inspections included rust staining, areas of hollow-sounding concrete, cracking and localised areas of missing concrete - all relating to corroding reinforcement. Various non-destructive and destructive tests were carried out on selected parts of the structure. These involved cover meter and hammer-tap surveys; chloride content testing; concrete core removal to derive equivalent cube strengths and for use with petrographic examinations; and localised breaking-out of concrete in the hangers to examine the condition of the reinforcement. In summary, very high chloride content levels were present throughout the structure which, whilst not affecting the integrity of concrete directly, provided a mechanism for reinforcement corrosion to occur. Based on the results it was concluded that the concrete, excluding the concrete in the cover zone, was of a sound nature. Modelling and Analysis Based on the original construction drawings and the information gathered during the principal inspection, RPS carried out a finite element assessment of the structure using LUSAS. Structural member stiffnesses were calculated neglecting the cover layer concrete. Structural member resistances were calculated using half the reinforcement as indicated in the construction drawings. The results indicated that the structure was still adequate for continued use due to good reserves of structural resistance to applied dead and live loading effects. However, because the central suspended span of the deck was relying on reinforced concrete hangers in direct tension and there was high chloride-induced steel corrosion throughout the structure, it was recommended that the hangers be strengthened and that measures be taken to halt the corrosion of reinforcement in the structure. A monitoring regime was set-up on the structure with inspections at six-monthly intervals.

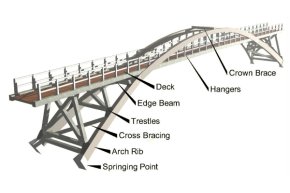

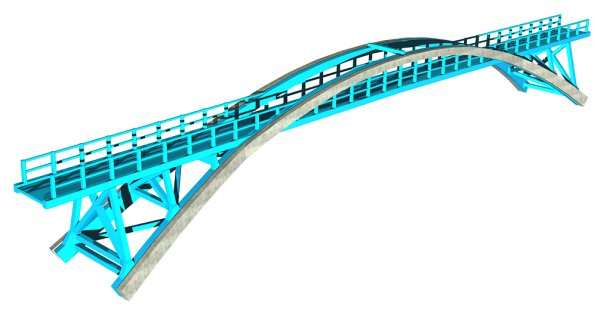

LUSAS Model of Original Mizen Head Footbridge In 2004, RPS produced a preliminary report for strengthening the bridge recommending the reinforcement of hangers with Near Surface Mounted Fibre Reinforced Polymer (NSM FRP) bars, concrete repairs to repair defects the installation of a cathodic protection system to stall the rate of reinforcement corrosion. But subsequent electrical continuity testing of reinforcement in the structure in 2005 by specialist contractors showed that there was insufficient general continuity of reinforcement steel to allow a cathodic protection system to be used, and as a result the footbridge was closed to pedestrian traffic. In June 2005, an access scaffold was installed to allow access to Mizen Head to be maintained until a permanent solution was developed. New Mizen Head Footbridge After considering a number of total replacement options, the construction of a new two-pinned concrete arch bridge with a 120 year design life was eventually chosen. This client-preferred scheme produced a visual replica of the existing bridge and had the benefit of a 700mm wider deck. It required the initial construction of new arch ribs parallel to and outside the existing ribs, using the existing ribs (which were strengthened as required) as falsework. The sequential demolition of the existing bridge could then take place, followed by the construction of new trestles, edge beams, hangers and deck slab. Existing mass concrete foundations at the arch springing points and deck ends were retained, and stainless steel reinforcement was used throughout. A 52m long, temporary steel truss was used to span across and above the existing bridge deck to provide support to the main scaffold and act as a fail-safe for the various temporary works.

Construction of new arch ribs alongside original Mizen Head Footbridge showing access scaffold supported from temporary truss. Modelling and Analysis Modelling and analysis for the new structure was again undertaken using LUSAS with design being carried out to British Standard BS5400. Live loading consisted of 5kN/m2 nominal pedestrian loading and a maintenance vehicle load case. The LUSAS model used for designing the new permanent structure was also a 3D thick beam model, but wider than the old model as the new structure was built outside the old one. RPS Consulting Engineer Ltd.’s resident engineer was also one of its design team and had a LUSAS model running on site to check the old and new bridges for all stages of construction and demolition process. Kieran Ruane, Technical Director of RPS Consulting Engineers Ltd. explains: We set up monitoring points on the old structure and modelled the loading situations as the temporary works loads came on, followed by the load from the new arch ribs. Once the new arch ribs were braced, they were used to support the temporary works and allowed the demolition of the old bridge." In summary he said: "It was a very interesting project to have been involved with, not only because of its complexity, but because of the project’s timescale we ended up using variations of our LUSAS model for assessment, design and construction over a period of 10 years. Open to the Public New Mizen Head Footbridge opened to the public on St Patrick’s Day, 17th March 2011. Fáilte Ireland, the Commissioners of Irish Lights, and Cork County Council jointly funded the Euro1.8 million rebuilding contract. It was delivered safely, within budget and stands as testimony to a very successful collaboration between the client, Cork County Council, the contractor, Carillion Irishenco Ltd, RB International - the contractor's construction engineer, and RPS Consulting Engineers Ltd. In the news: "It was a very interesting project, not only because of its complexity, but because of the project timescale we used variations of our LUSAS model for assessment, design and construction over a period of 10 years." Kieran Ruane, Technical Director, RPS Consulting Engineers Ltd. Share this article

Find out more

Other LUSAS Bridge case studies:

|

|

Software Information

|

||||||||

|