Software Tour

Staged construction

modelling

Staged construction

modelling is essential for many forms of bridge design and

construction, whether it be for carrying out a detailed analysis of an

incrementally launched segmentally constructed box girder bridge,

modelling cable or hanger replacements for cable stayed and suspension

bridges, or modelling a demolition process.

LUSAS provides you with

the means to model the construction, rebuilding or demolition of your

structure over time, and evaluate the effects of structural changes,

load applications, and any time-dependent material changes.

The

modelling process

With LUSAS

Bridge, unlike some software, only one model file need be created and

this can contain all of the information required to carry out an

analysis of every stage of construction. The effects of geometric and

material nonlinearity, and time-dependent material effects such as

creep and shrinkage can all be included.

-

Control

a complete staged construction modelling process inside the

Analyses panel of the LUSAS treeview.

-

Use

branched analyses to investigate the structural response at chosen

stages.

-

Activate

and deactivate the chosen parts of a model, and their associated

element and attributes.

-

Carry

supports forward between loadcases, or introduce or remove them to

accurately represent each stage.

-

Produce

construction history tables containing displacement history and

incremental displacement results.

Time Management

Use the

time management facility to manage a simple construction schedule and easily adjust

the duration of pre-defined construction stages in a staged

construction analysis. Easily and

automatically update the total response time values in nonlinear and

transient controls that have been previously specified for each

loadcase of a staged construction analysis.

Staged construction with

LUSAS

-

Model full staged construction

with beams, shells and solid elements (some software only

permits beams to be used)

-

Full activation and

deactivation of elements is supported

-

Model any support condition

and add or remove supports as required during the

construction sequence

-

Sliding bearings may be modelled using nonlinear contact (slidelines)

-

Support and loading facilities

including temporary/traveller loads

-

Apply loads anywhere onto any

model

-

Change loading/stress/strain

over time and lock- in stresses, if applicable, between stages

-

Prescribed displacements or jacking loads may be used as spans

are completed

-

Time-dependent material

properties include stress related concrete creep and

shrinkage to CEB-FIP Model Code 1990, (and others) and includes creep

recovery

-

Custom time-dependent curves

for particular material properties and codes

-

Use single or multi-tendon

wizards to define and assign tendon properties and

time-stages to features of a model.

-

Steel relaxation, time effect

on elastic modulus, tendon post-tensioning losses from

creep, shrinkage, and superimposed loads

-

Cumulative effects can be

reported separately for each loadcase, such as

post-tensioning effects, or for the effects of just creep and

shrinkage

-

Incremental effects can also

be specified allowing you to view and assess the net changes

to the structure since the previous stage.

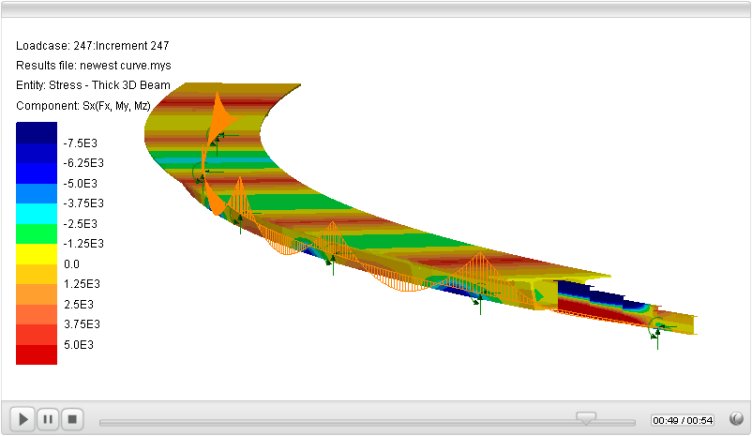

Animation of axial

forces in members during dismantling of the San Francisco-Oakland Bay Bridge East Main Span.

Use for

Use for

all types of staged construction methods and bridge types including:

-

Staged

placement of beams and slab for continuous structures

-

Cast

insitu span-by-span construction of continuous beams

-

Precast

segmental span-by-span erection

-

Cast

insitu balanced cantilever construction

-

Precast

segmental balanced cantilever construction

-

Progressive

erection of precast segmental decks

-

Incremental

launching

-

Balanced

placement for cable-stayed bridges

-

Composite

decks

-

Extradosed

bridges

-

Suspension

bridges

Span-by-span example

The erection of all segments

for a span in a set, which is then aligned, jointed, and

ultimately, usually, longitudinally post-tensioned together to

make a complete span. In LUSAS, this can be modelled

as a line beam model with optional fleshing of the deck

cross-section to show results contours.

The

animation below shows the construction sequence for the twin rib

span-by-span example shown (substructure not included).

The

analysis can incorporate post-tensioning

between stages, and creep effects as construction

continues, as required.

Balanced cantilever

The building of a bridge

superstructure from both sides of a pier in a scales-like

fashion.

Using LUSAS, creep

/ shrinkage analysis can incorporate an age attribute (for precast elements)

and checks on robustness

can also be made as, for example, where a segment may be

inadvertantly dropped by crane and where dynamic effects (impulse)

are important. 2nd order (P-delta) effects could also be included.

|

Incremental launching

Incremental launching

involves the casting of a continous

chain of bridge segments on-site adjacent to the actual

location of the bridge and then pushing the growing

superstructure out over temporary and permanent supports at

the bridge's location - as used in the construction of the Blackwater

Viaduct in the Republic of Ireland.

Using LUSAS, incremental

launching can be carried out for both in-line deck launching,

or for a curved deck launch. Modelling of incremental

launching can be done by activating and moving a

series of supports backwards under a model that is

incrementally being added to. This can be done via general

modelling facilities, or by scripting methods to automate the

modelling process.

|

|

An example of this method for a

box girder bridge with a simplified nose is shown below.

Curved deck

launching

Click to play movie (in new window).

Staged

Construction Modelling : Case Study

The initial

proposed I95

Mississippi

River Bridge was designed to be a record-breaking, cable-stayed structure

linking the States of Illinois and Missouri in the USA, helping to

relieve traffic on existing bridges across the river. Designed

by Modjeski & Masters for its clients Missouri and Illinois

Departments of Transportation, staged construction facilities in

LUSAS Bridge were used to model an 800 day construction

period, followed by a 10000 day period to allow for creep

over that length of time.

Geotechnical / Soil-structure interaction modelling

Find out more

|