Case Study

Approach

viaduct design for the Vasco Da Gama bridge

-

reinforced concrete diaphragms

-

prestress analysis and seismic loading

-

reinforcement quantities calculated

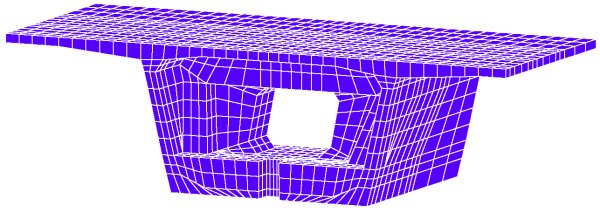

Kvaerner Technology Ltd is one of a consortium of companies designing

the New Tagus Crossing in Lisbon, Portugal. It used the extensive solid modelling

capabilities of LUSAS Bridge for analysing reinforced concrete diaphragms on the

6.5km long central viaduct section of the crossing.

Each 77m long viaduct span unit consists of 8 precast box sections that

are assembled, prestressed and concreted together before floating out and jacking into

position onto piers initially on temporary supports. Once adjoining spans are in place,

continuity prestress tendons are fixed through the diaphragm walls into adjacent units and

a 1m wide 'working-room' gap between units is infilled with concrete to match web and

flange thicknesses of adjoining units. A pair of 1m x 1m permanent bearings are installed

directly under the infill concrete and all temporary supports are removed.

Three different diaphragm designs were required to

cater for standard span units; special 'lay-by' units - with wider decks and with thicker

walls; and for units with movement joints. Different LUSAS models were required for each

diaphragm type in order to analyse the stresses due to deck loadings, anchorage forces

from prestress and bearing reactions. Models of the end 6m of each span unit type were

built using 8-node enhanced strain solid brick elements. Spring supports represented

bearings and dead, supported, live, and seismic loadings all had to be considered.

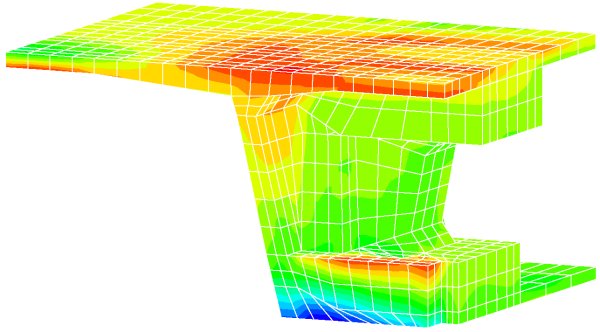

LUSAS was used to analyse 3 stages of

construction: Stage 1 prestress in the casting yard; Stage 2 prestress once the units are

in final position with infill zones concreted; and Stage 3, to give bearing reactions

under normal and seismic loading. A linear static analysis was completed for the various

loadcases and, by use of the LUSAS slice section facility, moments and forces at critical

sections through the webs and flanges of the diaphragms were easily obtained to allow the

diaphragm reinforcement quantities to be calculated.

"This was the first

time I had used LUSAS. I found it easy to use and by using the slice

section facility we obtained a better understanding of the behaviour of the structure.

This helped us to produce a detailed design which could not have been done easily using

alternative simplified methods".

Walid Mahmoud,

Senior Bridge Engineer, Kvaerner Technology Ltd

Find out more

Other LUSAS Bridge case studies:

|