Case

Study Case

Study

Pilsen Footbridge

- Analysis and assessment of the

behaviour of a dynamically sensitive footbridge

- Pedestrian load modelling to EN

1991-2 (Draft version)

- Optimisation and installation

of a tuned mass damper for pedestrian comfort

Pontex Consulting

Engineers Ltd. used LUSAS Bridge to assist with its analysis and

assessment of the dynamic behaviour of a slender decked, steel cable

stayed bridge on behalf of the Roads and Motorways Directorate of

the Czech Republic. Finite element analysis and dynamic loading

tests showed that the structure was susceptible to pedestrian

loading, and especially by vandalism, meaning that an energy

dissipation device needed to be installed. After the design and

installation of a tuned mass damper a second dynamic loading testwas

carried out, proving the effectiveness of the installed unit.

Overview

|

Pilsen Footbridge is a cable

stayed footbridge that spans around 65m across the D5

motorway near Plzen in the Czech Republic. The steel box

girder deck is supported by three pairs of 40mm diameter

fore-stays anchored into a 24m high, steel pylon which, in

turn, is anchored by three pairs of 50mm diameter back stays

into a substantial piled concrete foundation. The pylon has

a ball and socket joint at its base. The box girder is

supported by articulated steel bearings. During tender

design (by others) a tuned mass damper was seen to be

necessary. Final detailed design saw some re-design to parts

of the bridge but it remained very dynamically sensitive to

live load, showing that some form of passive damping was

still required.

|

|

|

|

|

Schematic

elevation of footbridge

|

Modelling with LUSAS

A 3D model was created in LUSAS to

examine the dynamic behaviour of the structure. Beam elements

represented the deck and pylon members and bar elements modelled the

cables. From the LUSAS analysis natural frequencies and mode shapes

for the structure were obtained and the first two modes in the

vertical direction were found to be within a specified problematic

range. As a result a pedestrian loading assessment was carried out

based on a draft copy of EN1991-2. This involved assessing three

pedestrian loading situations:

- A group of pedestrians modelled by

a pulsating single force. (Loading type 1)

- A constant stream of pedestrians

modelled by a pulsating constant uniform load (Loading type 2)

- Vandalism where a group of ten people are effectively

jumping up and down together at

problematic frequencies. (Loading type 3)

Two models of the footbridge, one

without a tuned mass damper, and one with, were created and an

optimisation of TMD parameters was carried out. Dynamic response of

the structure was investigated using the modal superposition method

involving step-by-step analysis.

|

|

|

|

1st vertical

bending mode (without a TMD installed).

Natural frequency = 1.33 Hz |

2nd vertical

bending mode (without a TMD installed).

Natural frequency = 2.93 Hz |

| |

|

Calculated

dynamic responses to pedestrian loading

Welded steel structures generally

have very low damping. A viscous

damping ratio of 0.5% was therefore used for all mode shapes

in the dynamic analysis. For pedestrian

comfort, and in addition to having to meet specified displacement criteria, an acceleration

comfort value of less

than 0.7m/s2 had to be met. From LUSAS analyses of the

three pedestrian loading types it was seen that this value was

greatly exceeded by the group of pedestrian loading (1.8m/s2),

let alone a moving stream of people (11m/s2), so the

installation of a tuned mass damper was

chosen as the best solution to reduce the structural response.

|

|

|

|

Displacement response from a

group and flow (stream) of pedestrians (loading types 1 and

2) |

Acceleration response from a

group and flow (stream) of pedestrians (loading types 1 and

2) |

|

|

|

|

Acceleration

response from vandalism loading

(loading type 3) |

Summary of

maximum accelerations and displacements for pedestrian

loading types 1,2 3 and 3 |

Tuned Mass Damper

assessment

| A

LUSAS analysis to assess the installation of a tuned mass

damper was carried out using TMD parameters that were chosen according to Bachmann and Weber

(1995). This resulted in a modal mass of 2 tonnes being used

along with a frequency of 0.95 of the natural frequency of the

structure that was to be damped. The results showed that vertical

acceleration at the critical location in the deck would be

reduced to just 0.1m/s2 for the pedestrian group

loading and 0.56m/s2 for the flow (stream) of

pedestrians. Acceleration response due to vandalism was

similarly reduced to a value of 0.5m/s2,

satisfying this particular comfort criteria. Maximum

vertical displacement values were also substantially

reduced. The maximum displacement caused by a flow of

pedestrians, for example, reduced from 158mm to just 6mm. |

Calculated

acceleration

response from vandalism loading

(with a TMD installed) |

In Situ Dynamic

Loading Tests

After the final construction works

had been carried out the bridge was subjected to an in situ dynamic loading

test. The aim was to measure the natural frequencies, derive mode

shapes, evaluate the response of the structure to different types of

human loading and assess initial damping requirements. A variety of

walking, swaying and running loadcases were undertaken at critical

frequencies of the first and second vertical bending modes and this

included a vandalism case of ten people swaying at the location where

the displacement in the deck would be greatest for the first

vertical bending mode. Measured results were compared against those

calculated by LUSAS and found to be in good agreement. At the

time of this first loading test the mass of the real footbridge was

less than the mass of the LUSAS models but allowance was made for

this in the final design of the TMD.

The installed tuned mass damper

parameters were based upon the results of the first in situ dynamic

loading test and on Pontex Ltd’s stated requirements. Four viscous

dampers with a combined damping value of 1500Ns/m were employed in

a pair of units that were located inside the deck 30.6m from the end furthest

from the pylon.

|

|

|

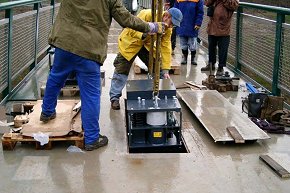

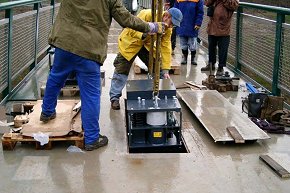

| Tuned

Mass Damper installation |

Following the installation of the TMD

the same dynamic pedestrian loading as used on the first test was

carried out on the footbridge. Measurements showed that, with the

TMD fitted and for the critical case of deliberate

vandalism, the acceleration in the deck was reduced to just

one-tenth of its previous value.

|

|

|

|

Measured

response of the deck to vandalism loading (without and with

TMD installed) |

|

|

|

|

Completed

structure |

"By using LUSAS we obtained a good correlation of the measured

frequencies and successfully designed and tested a tuned mass damper to restrict

deck movement for all the pedestrian loadings that were considered."

Milan

Kalný,

Technical Director, Pontex Consulting Engineers Ltd.

Find out more

Other LUSAS Bridge case studies:

|