Case Study Case Study

Share this

article

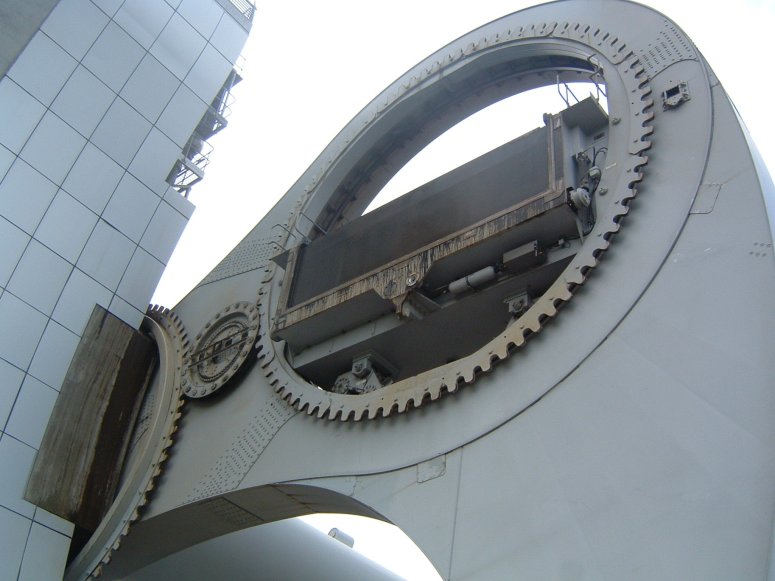

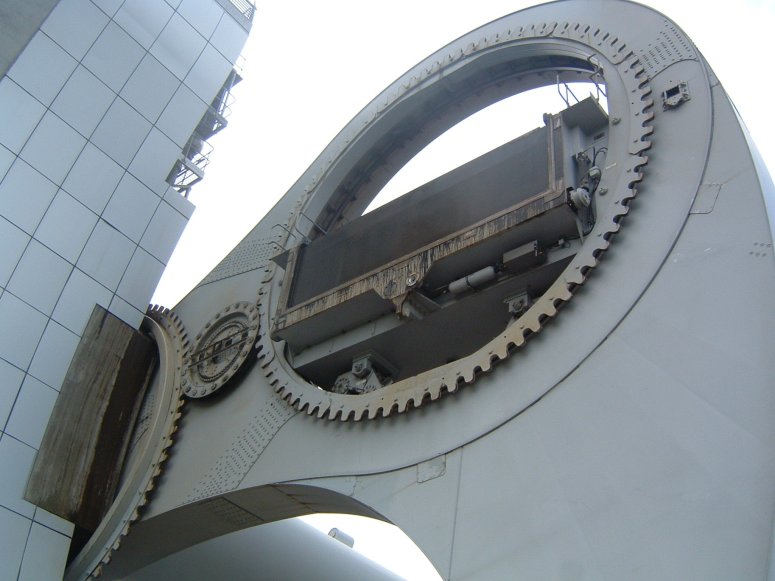

Falkirk Wheel

- unique steel rotating boat lift

- linear and nonlinear analysis

- solid element modelling of movement sensitive connections

LUSAS Bridge analysis software was used as the primary analysis

tool by Tony Gee and Partners (TGP) for preliminary and

subsequent detailed design work on the Falkirk Wheel. The Wheel (as it is known) is a

unique lifting bridge designed to reconnect the Forth & Clyde and Union canals between

Glasgow and Edinburgh in Scotland. It is the world’s first rotating boat lift and the

first boat lift to be built in the UK since 1875.

Overview

The project is part of a £78m British

Waterways scheme to restore the two canals to their former glory. Construction of the

interchange section, which comprises the Wheel, an elevated aqueduct at its upper end and

a holding basin at its lower, is being led by a joint venture of Morrison and

Bachy-Soletanche. Butterley Engineering, designers and manufacturers of the wheel, Tony

Gee and Partners, structural engineering specialists and Bennett Associates, M&E

engineering specialists and architects RMJM Scotland Ltd. complete the team.

The Wheel has an outside diameter of 35m, and comprises two 1.4m wide

steel, clawed arms rotating on a 3.5 m diameter axle. A pair of 25m long, 300 m3 water

filled caissons (or "gondolas") act as containers for boats which are lifted

through the 24m vertical distance between the two canals. Drive is provided at one end of

the axle through a system of hydraulic planetary gear units, with stability of the

caissons ensured by a network of synchronised gears. It is capable of carrying a total

payload of 600 tonnes in winds of Beaufort Force 6 (25-31 miles per hour). Boat transfer

time is about 15 minutes.

The uniqueness of the structure required TGP to employ some innovative

and unconventional design methods. UK design codes for bridges, buildings and floating

vessels were utilised, as well as Norwegian, German and American codes for such criteria

as thin walled cylinder behaviour and constrained ice loading. A 1:50 scale model was used

in a wind-tunnel for testing aerodynamic effects. Finite element analysis using LUSAS Bridge

aided the structural design and included nonlinear solid continuum modelling of movement

sensitive connections.

| Modelling with LUSAS

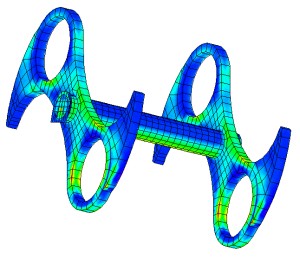

Detailed analysis made use of three separate LUSAS

models:

- A 3D

linear elastic shell element model allowed for analysing the axle and arms of the main

structure.

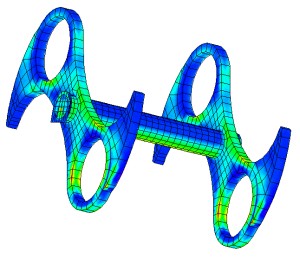

- A 3D linear elastic model using a combination of shell and beam elements

modelled one of the gondolas (shown below).

Both these models, as well as being the basis of the

material design (via the stress outputs), were particularly useful in estimating deflected

shapes and displacements, which can have a critical influence on the moving parts of the

structure.

|

|

|

A 3D nonlinear solid continuum model was used to analyse a small part of a joint

in the main axle situated just inside the clawed arm. Richard Prosser, project engineer of

Tony Gee and Partners, said: "We needed assurance that the axially loaded joint would

not prise apart, and the results from the LUSAS model formed a vital part of this

assurance."

|

|

|

|

"We needed assurance that the axially loaded joint

(

in the main axle situated just inside the clawed arm) would

not prise apart, and the results from the LUSAS model formed a vital part of this

assurance." Richard Prosser,

Project Engineer,

Tony Gee and Partners.

Share this

article

Other LUSAS Bridge case studies:

|

Case Study

Case Study