Case Study

The assessment of box girder diaphragms with weak welds

- box girder crossheads on viaduct structures

- nonlinear yield check analysis

- strengthening work proved unnecessary by LUSAS

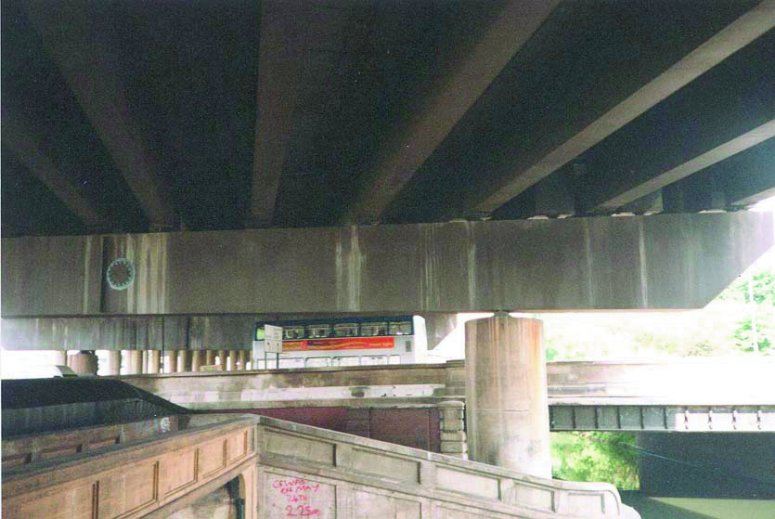

The Midland Links Viaducts carry the M5 and M6 Motorways around

Birmingham. A number of spans are supported on steel box girder crossheads and contain

strengthening details, added in the period following publication of the Merrison Report, which are not easily amenable to assessment using

codified methods. Maunsell Ltd

have

undertaken detailed nonlinear analysis using LUSAS Bridge, and have proved the

integrity of the diaphragms at the ultimate limit state.

Initial hand calculations to the methods in BS 5400 Part 3 indicated

that panels within the support diaphragms of these box girders would yield below ultimate

limit state loading. In addition, simple analysis suggested that the intermittent welds

between the diaphragm and the vertical stiffeners were also liable to yield. A linear

elastic analysis using LUSAS Bridge confirmed this, and a detailed materially and

geometrically nonlinear analysis was undertaken to prove the integrity of the diaphragms

at the ultimate limit state.

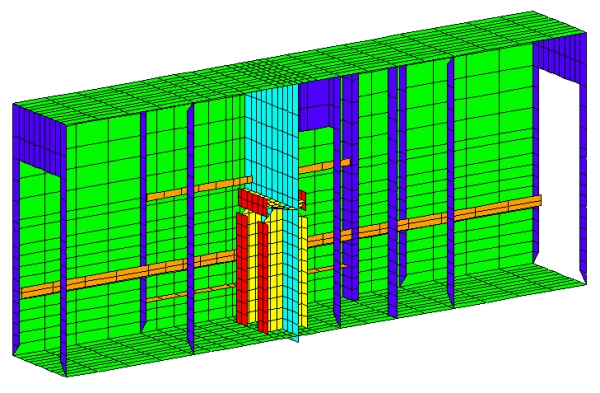

The diaphragm and the adjacent steel

plates of the structure were modelled using four noded thick shell elements. The diaphragm

stiffener welds were modelled using elastic / perfectly plastic joint elements with six

degrees of freedom. Elastic, plastic, and tension-hardening properties were assigned to the

shell elements. Yield forces for the joint elements were specified so that the resultant

forces in the joints were limited to values corresponding to the weld yield stress

predicted by assessment code BD21/97. The stiffnesses of the joints were chosen so that

onset of yield in the joint elements corresponded to a resultant weld deformation of no

more than 0.10mm, a value supported by research evidence.

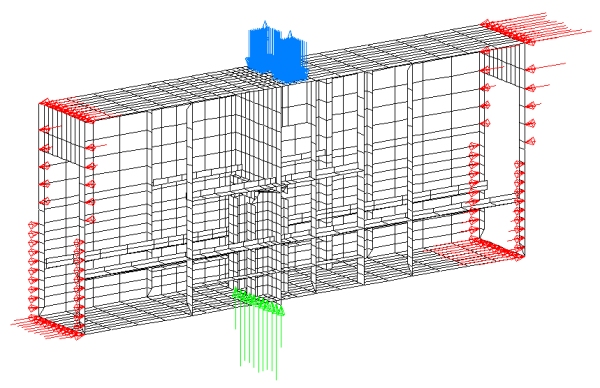

| Moments, shears and torsions at the ends of the

shell model and the reaction at the diaphragm base for the critical loadcase were

determined using a line beam analysis. These loads were applied to the model as

concentrated nodal loads. The load datasets were specified using variations, to simplify

input of the linear stress distribution produced by bending in the plane of the webs. To

allow for geometric imperfections within the diaphragm plates, a suitable deformed mesh

shape was created by analysing a through thickness temperature variation within the

diaphragm as an elastic loadcase. The resulting deformed mesh was then tabulated with the

structural loads.

|

|

|

|

| The extent of yield within the structure

was identified at each load increment by plotting yield flags. Animations of the deformed

mesh shape and stress contour plots at successive load increments showed how the diaphragm

redistributed load as it approached its limiting strength. Out of plane nodal displacement

histories for nodes within the diaphragm were plotted against total load factor to confirm

that buckling was not appreciable. The movement of the joint elements were output at each

load increment and a spreadsheet was used to plot graphs of the displacement profile along

the weld line for every load increment. These graphs proved that the deformation of the

welds would not exceed the limiting value of 1.0mm set as a safe limit, and showed that

potentially difficult strengthening work was unnecessary.

|

|

The Merrison Report was

the product of a Royal Commission set up following a number of high profile, catastrophic

collapses of box girders during the late 1960’s, including the Westgate Bridge in

Australia and Milford Haven in South Wales. The report included detailed design and

workmanship rules for box-girder bridges which were used to check all existing box

girders, and then used for detailed design until the introduction of BS5400: Part 3 in

1978. The Part 3 rules for diaphragms, in particular, are simpler to implement in a

"blank sheet of paper" design situation than the Merrison interim rules.

Find out more

Other LUSAS Bridge case studies:

|

|

Software Information

|